socks knitting machine socks machine

-

Supplier: Taizhou Jiaojiang Zhongwei Sewing Machine Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr. Zhu Chaozhi -

Price: $3500.00 /set -

Min. Order: 1 set

| Applicable Industries: | Building Material Shops; | Warranty: | 1 Year; |

| Packaging Detail: | export carton; | Payment Terms: | L/C,T/T; |

| Power(W): | 0.75kw; | Supply Ability: | 100 Set/Sets per Month; |

| Voltage: | 380v; | Port: | Ningbo; |

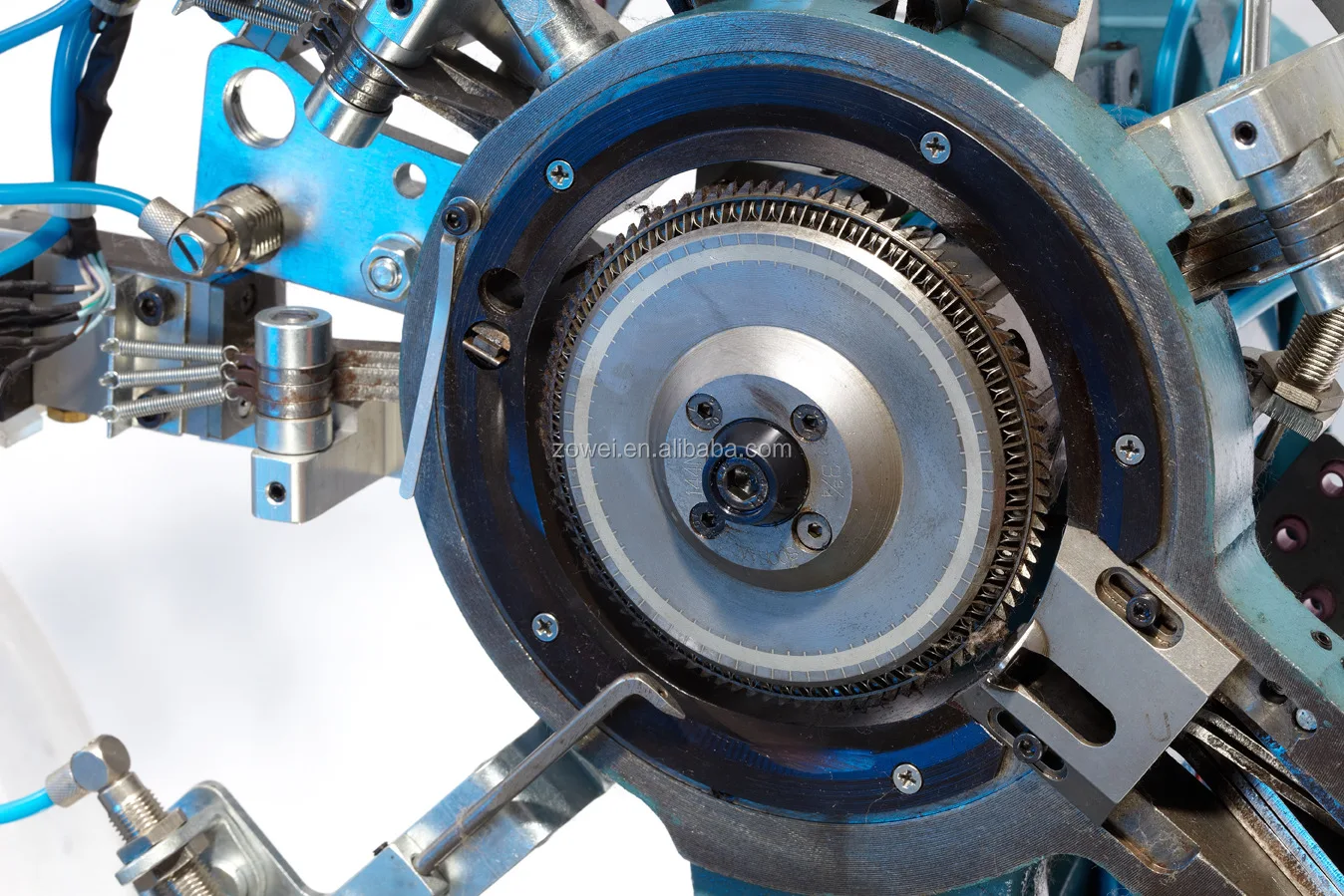

| Weight: | 380KG; | Type: | Jacquard Knitting Machine; |

| Socks Machine: | Knitting Machine; | MOQ: | 1set; |

| Dimension(L*W*H): | 110*120*250CM; | Brand Name: | ZOWEI; |

| Condition: | New; | After-sales Service Provided: | Free spare parts; |

| Place of Origin: | Zhejiang China (Mainland); | Certification: | CE; |

socks knitting machine socks machine

Main Character

1. It adopts computer controlled device, coder comes to zero position automatically, easy to operate.

2. It adopts clear and big display screen.

3. The system of lubricating oil adopts the Computer controlled procedure to add oil to guarantee the steady of it.

4. Problem checking is perfect, and protection system of thread-broken and needle-broken are very sensitive.

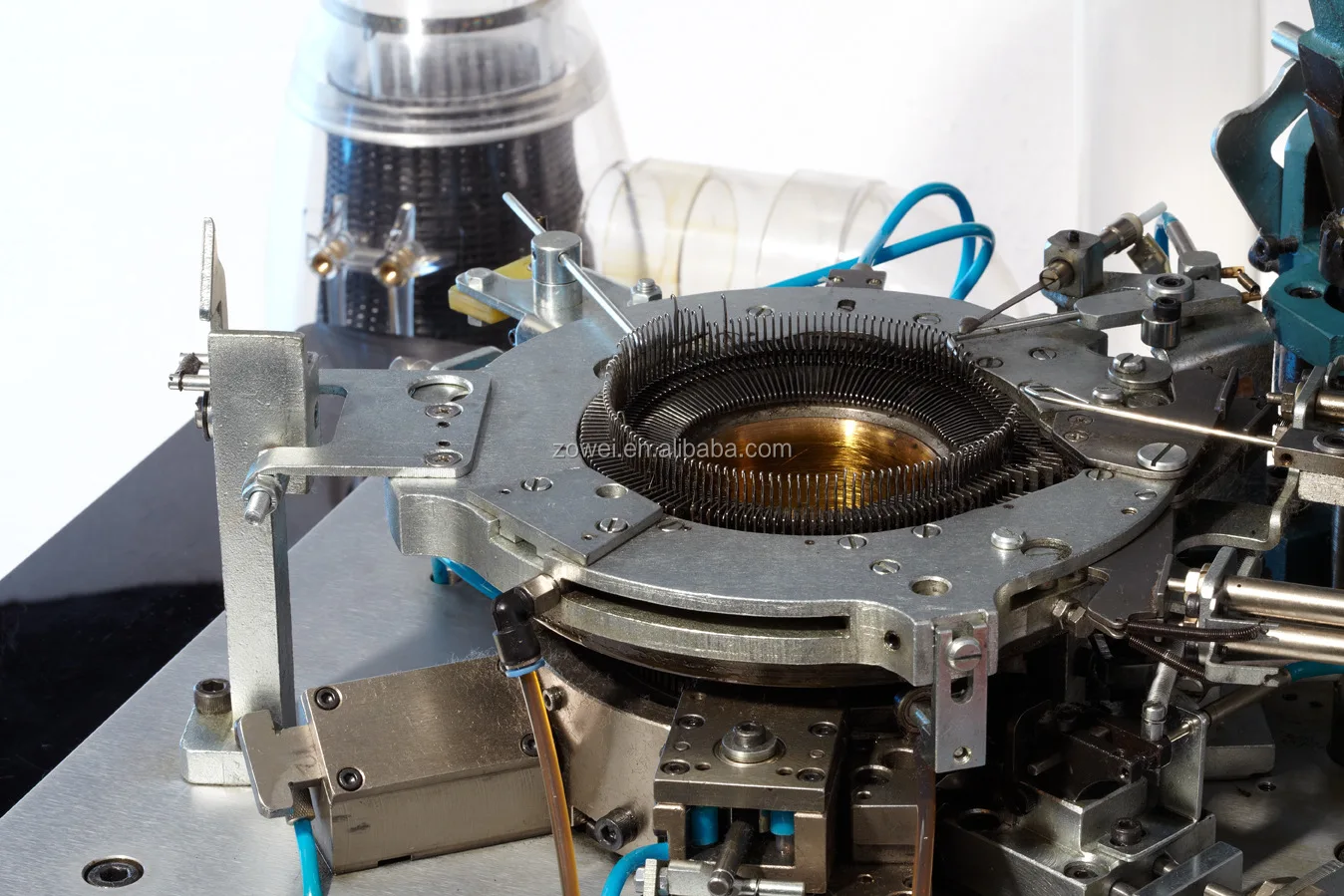

5. Higher speed cylinder cam, lower noise, and new type traction system.

6. High output double input yarn.

7. Adopts IC-transmit, the device of 12 suits electronic jacquard blade.

| PRODUCT PARAMETER | ||

| Model Number | ZW-606 | ZW-607 |

| Cylinder diameter | 4 '' | 4+1/2'' |

| Needle speed | 84~176N | 72~120N |

| Rotation speed | 250~300r/min | 200~260r/min |

| Power | 0.75KW | 0.75KW |

| Dimension | 110×120×250 (W×L×H,cm) | 110×120×250 (W×L×H,cm)

|

| Weight | 380KG | 380KG |

| Weavable | can knit plsin, rib, piwue socks | can knit plsin, rib, piwue socks |

| Control | Controlled by computer | Controlled by computer |

| Protection System | Fault detection, broken wire, broken needle | Fault detection, broken wire, broken needle |

| Lubrication System | Computer controlled refueling | Computer controlled refueling |

| Line entrance | High output double input yarn | High output double input yarn |

| Payment | T/T,L/C | T/T,L/C |

| Port | Ningbo/Shanghai | Ningbo/Shanghai |

Needle barrel diameter

3.5 inches

Pin number

72N-220N

Maximum speed

Three hundred and thirty

Drive Control Servomotor

Voltage 220V/380V

Main motor 1.1KW

Fan (> 1.1KW)

Control cabinet 0.8KW

Covering area 150'120'240 cm

Net weight 300 KG

Gross weight 350KG

Packing volume 111'77'176 cm

Main features and functions:

1. Each row can be woven with one main color and four auxiliary colors.

2. A sock can be woven into 15 colors.

3. All-computer control without drum. The main motor adopts 1.0RW servo motor.

4. All functions are controlled by electronic valves, rubber bands and density are accomplished by stepping motors.

5. High sensitivity protection device for wire breaking and needle breaking of full automatic lubricating oil system is adopted.

6. Using LCD, Chinese and English can choose by themselves.

7. Power failure or other reasons can preserve the pattern. Using USB pattern transmission USB can store multiple patterns, making the pattern change more reliable and stable.

8. The drawing system can be designed by WINDOW98/2000/XP.

9. Self-check the fault and stop automatically. The cause of the fault can be displayed on the LCD screen.

10. Double pins, reduce the turning distance, increase the output, more suitable for the production of three-dimensional socks.

11. Fuel refueling is controlled by full automatic program. After changing the needle barrel, the needle number and needle spacing are modified on the keyboard.

12. The machine uses suction nozzles specially designed for this machine to reduce the blockage of suction nozzles causing injection. The machine also uses reasonable waste silk recovery and double filters to make it easy for you to solve the blockage problem of suction doors and reduce the loss of suction fans.

13. All braiding processes are operated by computer-controlled air valves to reduce mechanical wear, which affects performance and increases maintenance burden.

14. The computer control area box can store two patterns at the same time, and can rotate freely. The left and right foot socks can automatically change their work after setting up.

15. Computers can also adjust scores automatically according to the structure of the human body to make the product more suitable.

16. Can knit plain weave, rib, mesh, ring, rubber jacquard, heel, anti-sock head, heel yarn change, multi-layer groove, sole reinforcement, left and right pattern socks.

-

Wanghu Sports 3.75 Inch Terry Socks Making Machine Kids Socks Machine

-

Zhengbao Automatic Round Sock Machine Price Sock Knitting Machinery For Making Socks

-

ROSSO-7F cotton socks knitting machine price is same as lonati machine

-

WLT-6F828 WEKNIT SOCKS MAKING MACHINE

-

HN Low Price Fully Automatic Computerized Socks Machine Making Socks

-

Quick Service Sock Making Knitting Machine Sock Knitting Machine

-

SOCKS MACHINES G615 High Quality Tights SANGIACOMO SANTONI Electronic Machine Best Quality Tights Socks Comfortable

-

Fully automatic computer hosiery machine with good quality and excellent price

-

Rosso 636 Straight Socks Automatic Threading Machine Sewing Machine Good Price

-

China Automatic Sock Knitting Machine Price