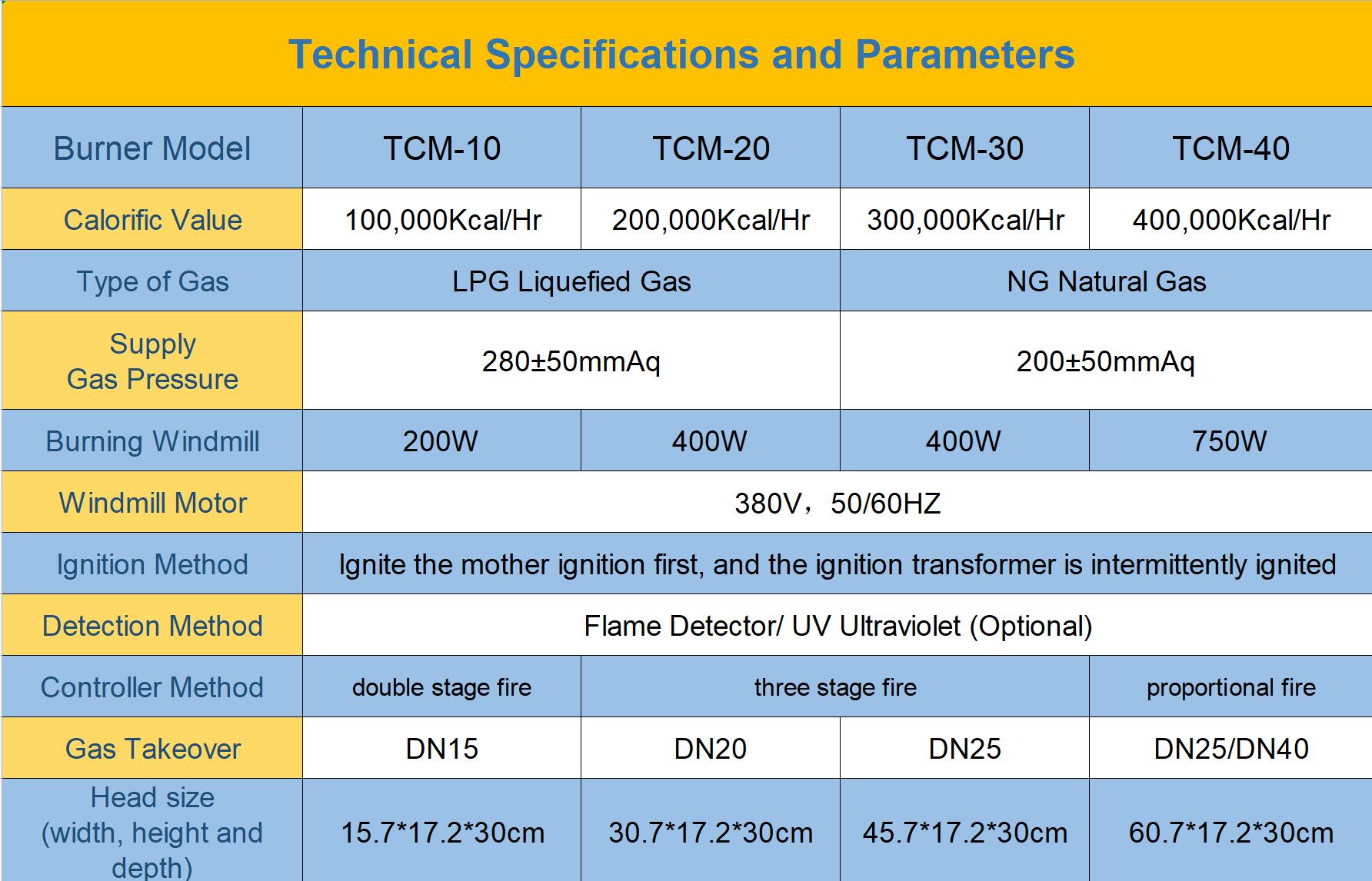

Two-Stage Gas Burner JATE TCM-10M1F Airflow Industrial Gas Linear Crossfire Burner with Fan Power 200W

-

Supplier: Shenzhen Jate Burners Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Jeanie Liu -

Price: $1020.00 / 1 - 1 pieces

$970.00 / 2 - 4 pieces

$943.00 / >=5 pieces -

Min. Order: 1 piece

Product details

| State of health: | new | total weight: | Roll weight about 99KG |

| Burner head: | 15.7*17.2*30cm | Video shipment inspection: | if |

| brand: | Jeter | Types of: | gas stove |

| Warranty: | 12 months, 1.5 years | Mechanical test report: | if |

| Model: | TCM-10M1F | Serve: | Online Video Support |

| port: | Shenzhen | place of origin; place of origin: | Guangdong, China |

| product name: | Linear Burner | Main caliber: | DN15 |

| Packaging Details: | Wooden packing | brand: | Jeter |

| Applicable industries: | Manufacturing Plants, Construction Works, Energy and Mining, Others | Supply capacity: | 100 pieces per month |

| Fan power: | 200W | payment terms: | Western Union, T/T, MoneyGram, Online Payment |

| deliver goods: | 3-5 days after shipment in full payment | Marketing Type: | normal product |

| Showroom location: | not any | Weight (kg): | 42 |

| Package preview: |

Product overview

Model | TCM-10M1F |

total weight | Roll weight about 99KG |

combustion head | 15.7*17.2*30cm |

Fan power | 200W |

basic introduction:

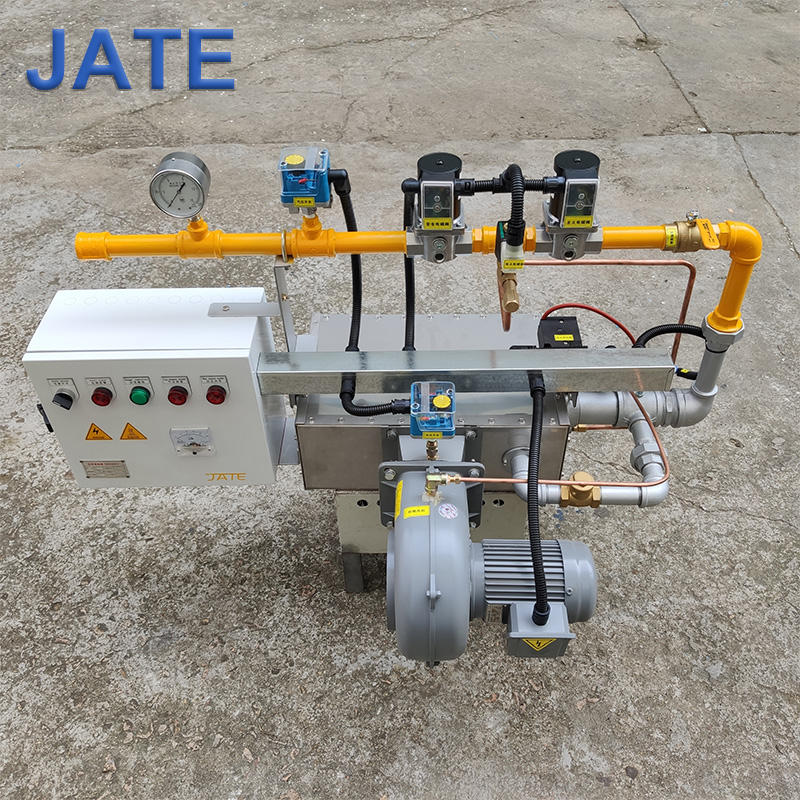

It is a linear burner, and the design of the linear gas nozzle makes the heat energy distributed evenly in the hot air system; The high-ratio firepower stepless adjustment saves energy, achieving the effects of precise temperature control, rapid heating and energy saving. High-efficiency air-heated fully automatic gas burner, a new type of burner designed to generate a large amount of hot air in industrial processes. It adopts a variety of air and gas mixed combustion methods, complete combustion, and saves energy (gas), which is incomparable to ordinary gun burners. A complete combustion fan is installed behind the burner steel casing. By providing appropriate air volume and air pressure, when the flow velocity in the air duct changes within a wide range, the fan can operate stably without installing deflectors around the burner.

List of functions

Proportion adjustment, realizing a high turndown ratio of 40:1; Short flame design, about 0.5m under standard conditions, and a safe burning distance of 2m; Simple operation, reliable operation year after year, small maintenance, and convenient repair; Integration Blower and steel casing, providing unparalleled air heating performance; Low-cost industrial-grade burner, easy to adjust the burner setting, good hot air uniformity; Stable combustion, wide application range, simple igniter structure, reliable action; Module Anti-corrosion and anti-corrosion design, can adapt to harsh environment, long service life;Dual Stage Gas Burner Jeter TCM-10M1F Linear burner with fan power 200W

Working principle: After the power system is connected, the gas and air pressure are detected synchronously, and the combustion fan starts to purge the furnace for 30 seconds. After everything passes normally, the ignition transformer is discharged according to the set time, and the main safety solenoid valve and the main fire solenoid valve are opened. Gas enters the nozzles from the main fire pipe. When encountering the open flame emitted by the ignition electrode, the gas is ignited and fully mixed with air. The flame detection rod or ultraviolet photoelectric cell can stably detect the flame signal. After the ignition is successful, the main gas valve is opened and the burner enters the normal working state. After the burner enters the normal working state, the PID adjustment method is adopted after the oven temperature is detected, and the gas flow is adjusted by the proportional motor to realize the control of the oven temperature. The safety system has been tracking and monitoring flame signal, gas pressure and combustion air pressure signal. If the flame goes out halfway or the gas pressure does not reach the specified value, it will automatically cut off the gas supply and give an alarm. After the burner alarms, it will not automatically re-ignite, and must be reset and checked manually. Only after the cause of the fault is identified and cleared, can a new round of ignition procedure be entered, and the new round of ignition procedure will repeat the entire ignition process to ensure the safety of personnel and equipment to the greatest extent.

positive image

back picture

real image

Control method introduction:double fire: There are two outputs of high fire and low fire. The small fire is also ignited as the main fire, and the constant fire works according to the instructions of the thermostat (switch). Adjustment.

Three stages of fire:There are three outputs: mother fire, small fire, and high fire. The main fire is ignited as a constant fire, and the rest work according to the instructions of the thermostat (switch). Shutdown adjustments.

Proportional adjustment type: On the basis of the standard progressive combustion, a proportional motor and a proportional butterfly valve are added to become a proportional regulating burner, so that the burner can stay at any point within the working range according to the signal of the sensor (thermostat 4-20MA current) , the system can always work in a balanced state, the fire turns smoothly, and the adjustment range is large.

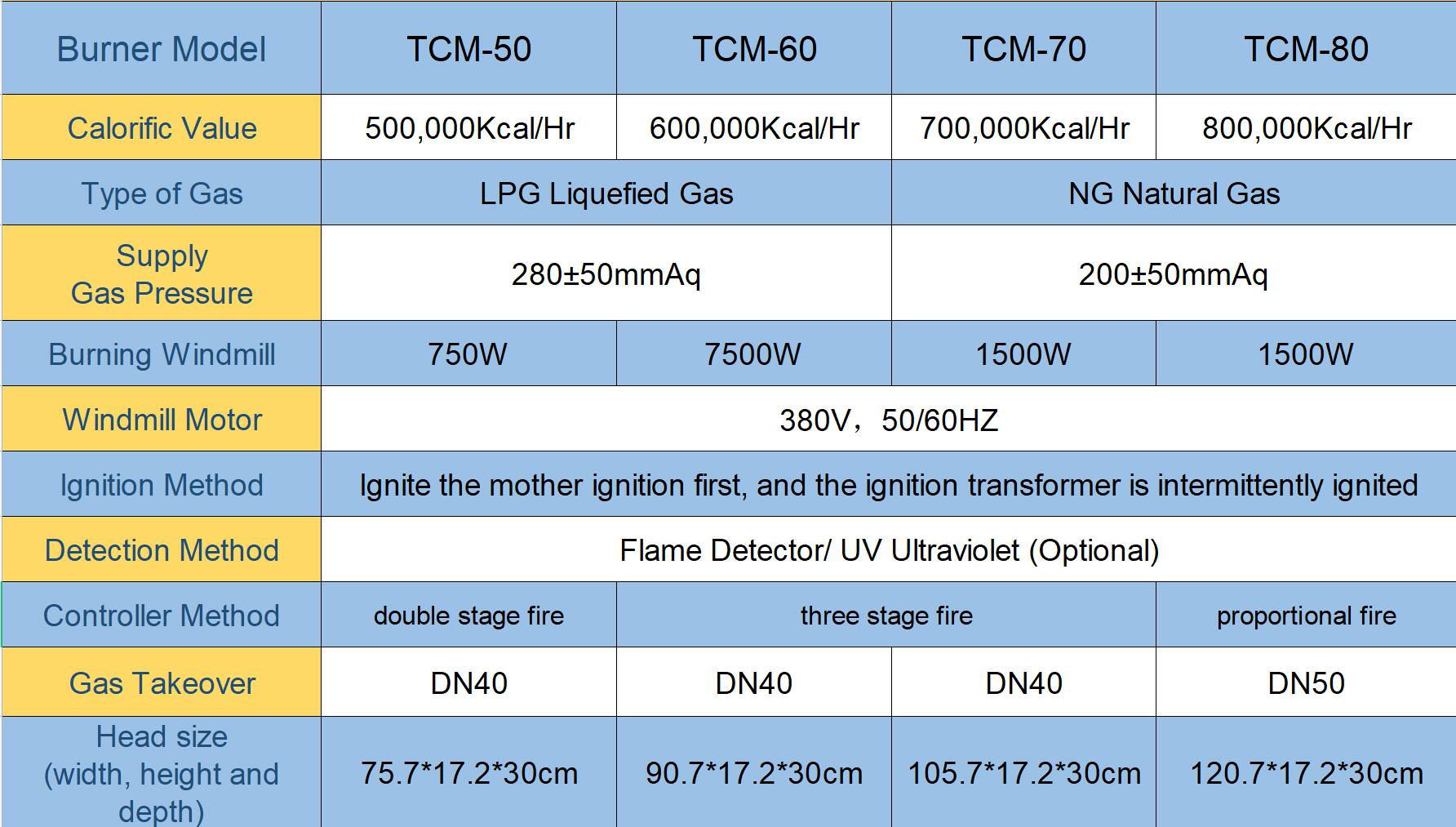

product configuration

Stove

control box

combustion fan

servo motor

TBC2800 controller

gas filter

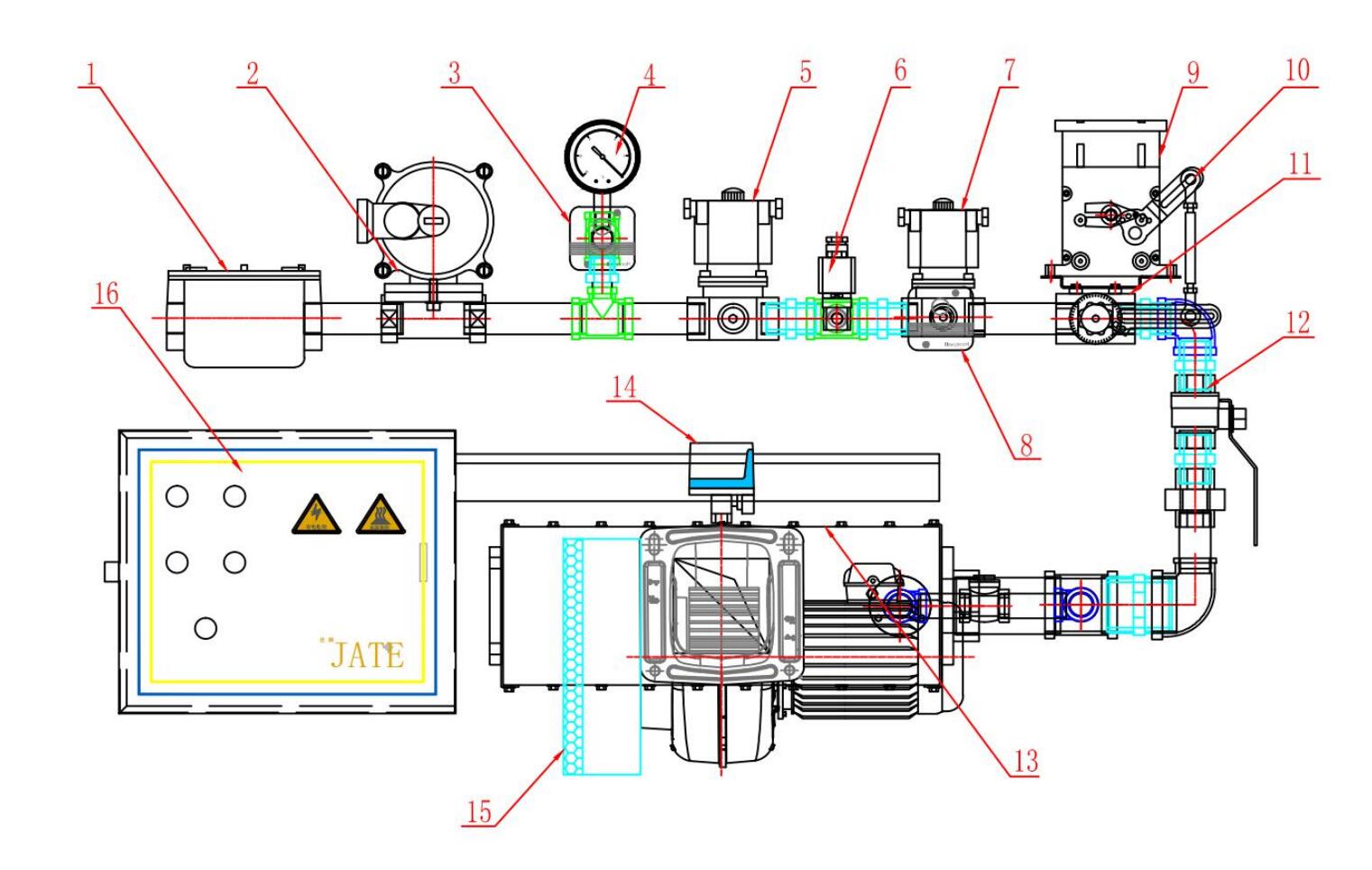

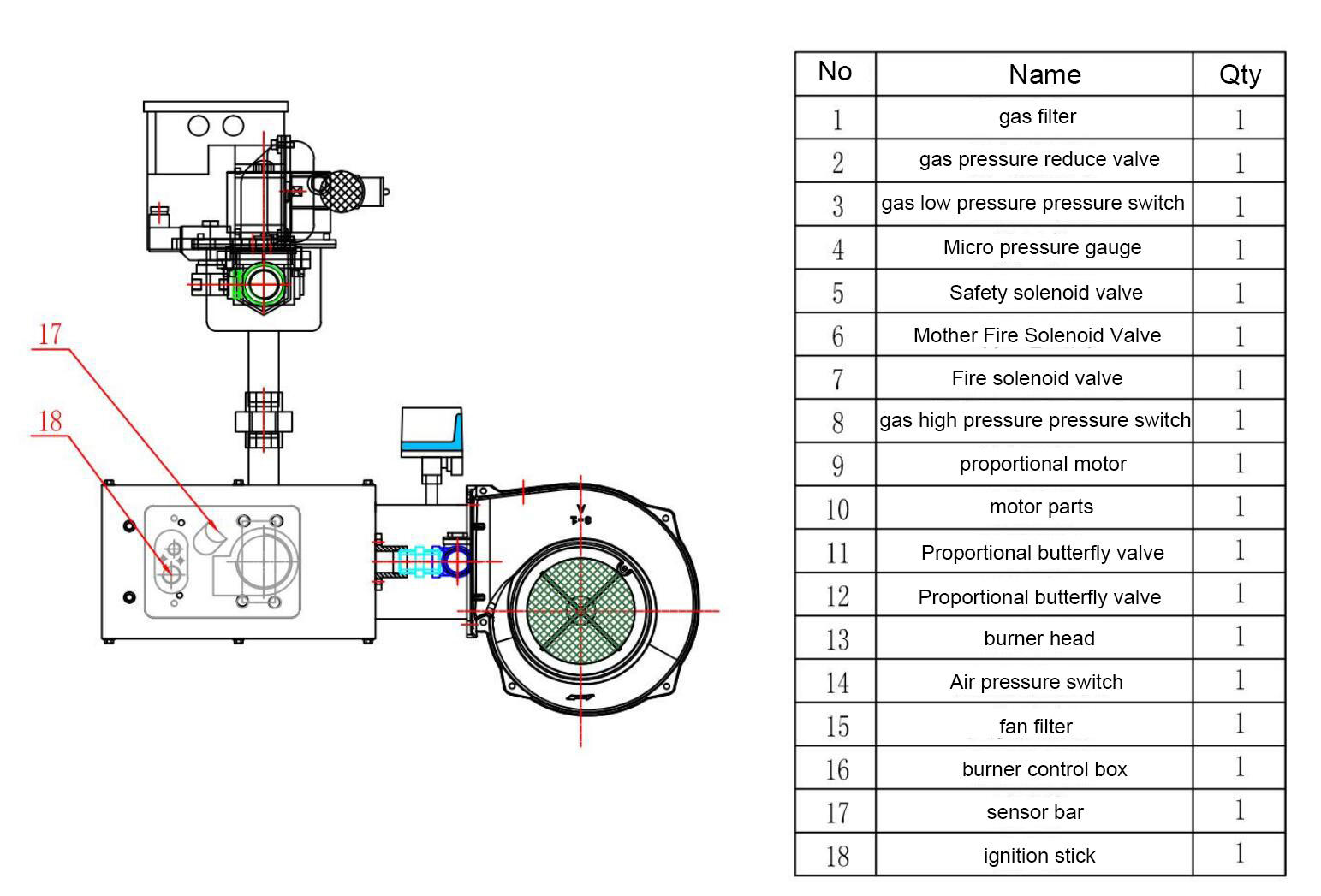

Takeover diagram (names of each part)

VIEW MORE

You may like

-

China factory hot selling DUNGS replacement pressure reducing valve, high quality burner parts

-

Pizza oven for industrial pizza China with small gas oven for sale

-

Furnace Industrial Gas Burner Manufacturer

-

Waste oil burner nozzle siphon type full cone oil fuel nozzle air atomization sprayer diesel heavy oil nozzle burner accessories

-

YORK Oil filter with AL cup for burner and boiler replaces Giuliani Anello oil filter

-

Bairan B26 light oil burner, diesel burner, primary fire burner

-

China cheap high quality small portable gas burner for pizza oven oven diameter 110cm-140cm NPG and LPG industrial gas burner

-

Two-stage gas burners RIELLO 40 FSD SERIES

-

High Quality Hot Sale Combination Boiler Spare Parts Air Pressure Switch Sensor Pump Motor - Copo Safety Valve

-

Hot Sale High Quality Combination Boiler Spare Parts and Accessories Gas Valve Expansion Tank Pressure Gauge