Plastic thermoforming machine hollow parts rock plastic thermoforming machine

-

Supplier: Shandong Jinxiu Shanhe Environmental Engineering Co., Ltd. -

Region: Shandong, China -

Contact: Ms Jane Wang -

Price: $16900.00 /set -

Min. Order: 1 set

| Health status: | new | Certification: | ISO9001:2008 |

| Package preview: | brand: | Splendid mountains and rivers | |

| Dimensions (L*W*H): | 5m*2m*2m | Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies |

| color: | blue green red gray etc. | Mechanical test report: | if |

| Video shipment inspection: | if | After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Supply capacity: | 20 sets per month | Automatic level: | fully automatic |

| Showroom location: | Bangladesh, none | MOQ: | 1 set |

| strength: | 6-100kw, 5500 | port: | Qingdao Port Tianjin Port Shanghai Port |

| After-sales service provided: | Video technical support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, online support | Origin: | Shandong China |

| custom made: | Yes | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Voltage: | 380V | weight: | 3000 kg |

| Warranty: | 1 year | Marketing Type: | New Products 2020 |

| Local service location: | not any | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Packaging Details: | The product is tailor-made for customers, and various options such as transportation and packaging are available for customers to choose | Core component warranty: | 1 year |

| Main selling points: | competitive price |

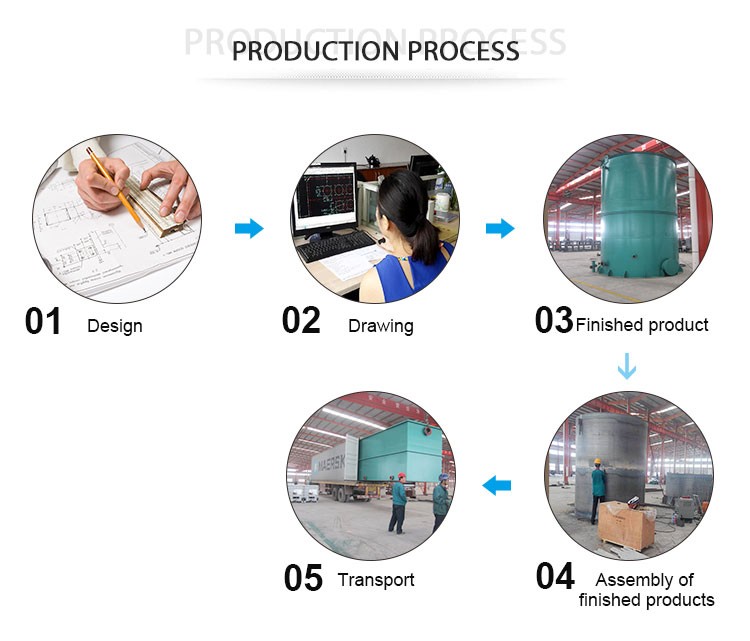

Mechanical production process of rotary rotomoulding plastic water tank

Working principle of rotational molding

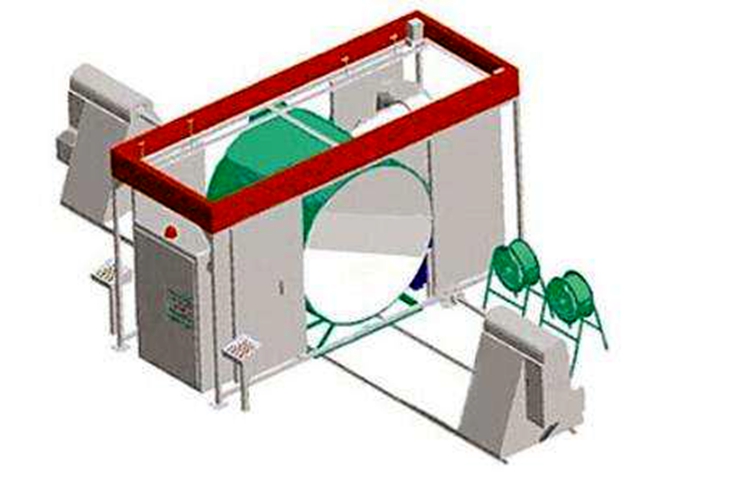

The unique design of the Roto molding machine allows for an even coating of plastic within each mold. The picture on the right is our stand-alone rotomolding machine. This is one of the most common machines in the industry. It has three arms. The machine is an independent model. Standalone machines can be equipped with up to three independently movable arms. This allows for molds of different sizes, with different heating and thickness needs. It consists of oven, cooling chamber and mold spindle. The spindle is mounted on a rotating axis to provide an even coating of the plastic within each mold.

The main attraction of rotational molding

:

Hollow parts can be molded in one piece with no weld lines or joints Molded parts are essentially stress free Molds are relatively cheap Mold maker lead times are relatively short Wall thickness can be very uniform (compared to other mold free surface molding methods such as blow molding ) Wall thickness distribution can be changed without modifying the mold - layer moldings, including foamed parts Different types of products can be molded together on one machine Inserts are relatively easy to mold High quality graphics can be molded

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* Check out our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers are available to service machinery overseas.

-

Factory high price water tank making machine, septic tank making rotomolding machine

-

Rising Sun Kayak Rotomolder For Sale

-

High Quality Full Printed Plastic Ocean Kids PVC Ball Making Rubber Toys Molding Machine PVC Ball Making Machine

-

PE 500L 1000L 2000L Rotational plastic water tank machinery

-

Exporter Hot Sale Heavy Duty 4 Arms Dual Axis Rotational Molding Machine For Industrial Use

-

500 liters 1000 liters vertical water tank plastic making machine rock rotomolding machine

-

Cheapest water tank making machine Open flame machine rotary machine

-

High quality custom plastic boat rotational molding machine mold

-

Balloon Making Products Machine Toy Making Rubber Soccer Small Printing Pvc Ball Making Machine

-

Rock & Roll Rotational Molding Machine For Water Tank Manufacturing For Sale

Other Products

-

$16800.00 / set

$16800.00 / set