Plastic rubber injection mould temperature controller

-

Supplier: Dongguan Naser Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Eva Shu -

Price: $500.00 /set -

Min. Order: 1 set

| Port: | shenzhen or Guangzhou; | Max temperature: | 200 degree C; |

| Temperature Range: | 40-200; | Type: | Water Temperature Machine; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union; | Power(W): | 12KW; |

| Brand Name: | Naser; | Application: | plastic mold; |

| Packaging Detail: | wooden case package; | Warranty: | 1 Year; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | pump power: | 0.37KW; |

| Product name: | Plastic rubber injection mould temperature controller; | Voltage: | 380V/50Hz; |

| Suitable for: | plastic mold; | Pump Max. Pressure: | 3.8; |

| Applicable Industries: | Hotels,Building Material Shops,Machinery Repair Shops,Food & Beverage Factory,Food & Beverage Shops,Advertising Company; | Condition: | New; |

| Supply Ability: | 500 Set/Sets per Month; | Certificate: | CE UL; |

| Weight: | 50; | Dimension(L*W*H): | 735*310*540; |

| Voltage: | 380-415V/50Hz(customized); | Place of Origin: | Guangdong China (Mainland); |

| After-sales Service Provided: | Video technical support,Free spare parts,Online support; | Temperature Control Accuracy: | 1C; |

| pump flow: | 30L/min; | Internal Piping Size: | 3/8"; |

| Cooling Method: | indirect; | Certification: | CE; |

Plastic rubber injection mould temperature controller

| Specifications: | |||||||||

| Model | Medium | Max Temp. | Electric Power (KW) | Pump Power (KW) | Pum Flow (L/Min) | Pump Max Pressure | Cooling Method | Dimension (MM) | Weight (KG) |

| NTCW-6L | Water | 120℃ | 6 | 0.37 | 30 | 3.8 | Direct | 735*310*540 | 30 |

| NTCW-9L | Water | 120℃ | 9 | 0.37 | 30 | 3.8 | Direct | 735*310*540 | 30 |

| NTCW-12L | Water | 120℃ | 12 | 0.75 | 50 | 4.8 | Direct | 735*310*540 | 50 |

| NTCW-24L | Water | 120℃ | 12*2 | 2.2 | 110 | 6 | Direct | 1100*600*600 | 110 |

| NTCW-36L | Water | 120℃ | 18*2 | 2.2 | 110 | 6 | Direct | 1100*600*600 | 110 |

| NTCW-50L | Water | 120℃ | 25*2 | 3.75 | 200 | 6 | Direct | 1350*700*700 | 200 |

| NTCO-6L | Oil | 200℃ | 6 | 0.37 | 30 | 3.8 | Indirect | 735*310*540 | 30 |

| NTCO-9L | Oil | 200℃ | 9 | 0.37 | 30 | 3.8 | Indirect | 735*310*540 | 30 |

| NTCO-12L | Oil | 200℃ | 12 | 0.75 | 50 | 4.8 | Indirect | 735*310*540 | 50 |

| NTCO-24L | Oil | 200℃ | 12*2 | 2.2 | 120 | 6 | Indirect | 1100*600*600 | 120 |

| NTCO-36L | Oil | 200℃ | 18*2 | 2.2 | 120 | 6 | Indirect | 1100*600*600 | 120 |

| NTCO-50L | Oil | 200℃ | 25*2 | 3.75 | 200 | 6 | Indirect | 1350*700*1000 | 200 |

Features:

1.Temperature controller adopts Japans and Italian (PID) programmed sensor

internal storage, which calculates automatically. 12KW PID controling mould temperature controller

Its precision is controlled within +1 and it can save above 35% power.

2. Two sets of tubular electric heating element can use one or both.

3. Short heating of cooling time and stable temperature.

4. Electric heating can is made of stainless steel.

5. Perfect security protection and fault indication system

6.Use the advanced unit from foreign countries with long life.

7. CAD system design that is easier to handle and maintain.

1.Free repair within 1 year of guarantee on the condition of operate the machine in the right way

2. Our factory provide machine testing when customer come to our factory to see this machine.

3.We provide detail machine technical specification, electric diagram, installation book, operating manual, drawings

4.We can provide engineers to customer's factory to help installation and training workers if customer required.

5.Standard voltage is 380V/3Phase/50Hz, or other voltage according to client's requirement.

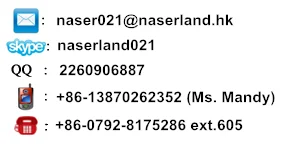

More informations, please contact:

-

6kw-48kw extrusion molding oil/water heating mold temperature controller

-

Oil Injection Mold Temperature Controller Plastic and Rubber Processing Machinery

-

YUDO controller standard 6 zone best price hot runner temperature controller system model

-

Injection mold temperature controller oil heater

-

Shini STM-910W Industrial Mold Temperature Controller/Plastic Water Mold Heater/Temperature Regulator a eau

-

High gloss multi-function RHCM injection mold temperature control unit

-

HUARE HMC-W rapid heating and high temperature resistant sealed water mold temperature machine 150

-

Yudo Hot Runner LCD Pid 1-24 Digital Zone Temperature Controller Price

-

Hot Runner Heating Oil Mold Temperature Controller For Injection Mold

-

Factory Price Oil Heating Mold Temperature Controller

Other Products

-

$1600.00 / set

$1600.00 / set