New sandblasting cabinet portable sandblasting machine sandblasting machine

-

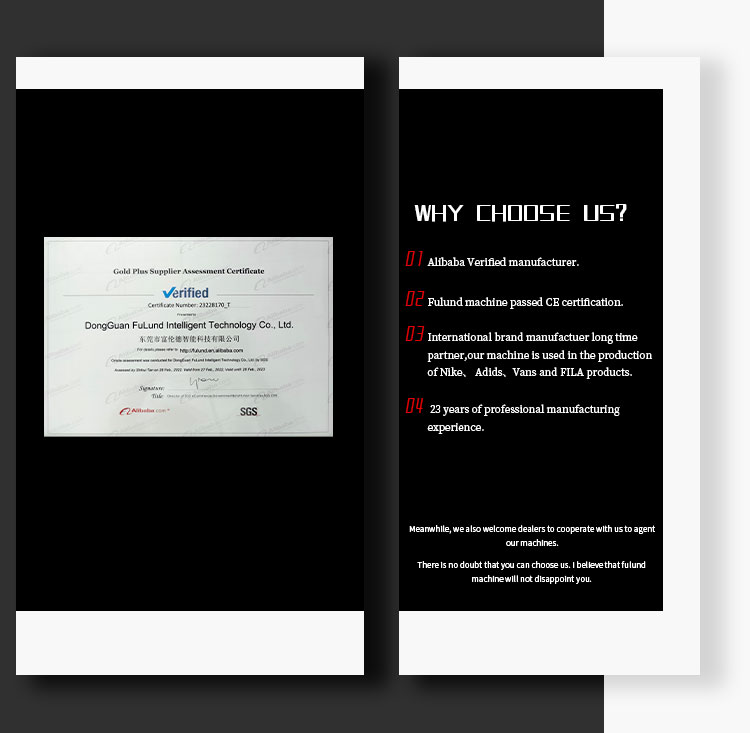

Supplier: DongGuan FuLund Intelligent Technology Co.,Ltd -

Region: Guangdong, China -

Contact: Mr Jeff Su -

Price: $100.00 /set -

Min. Order: 1 set

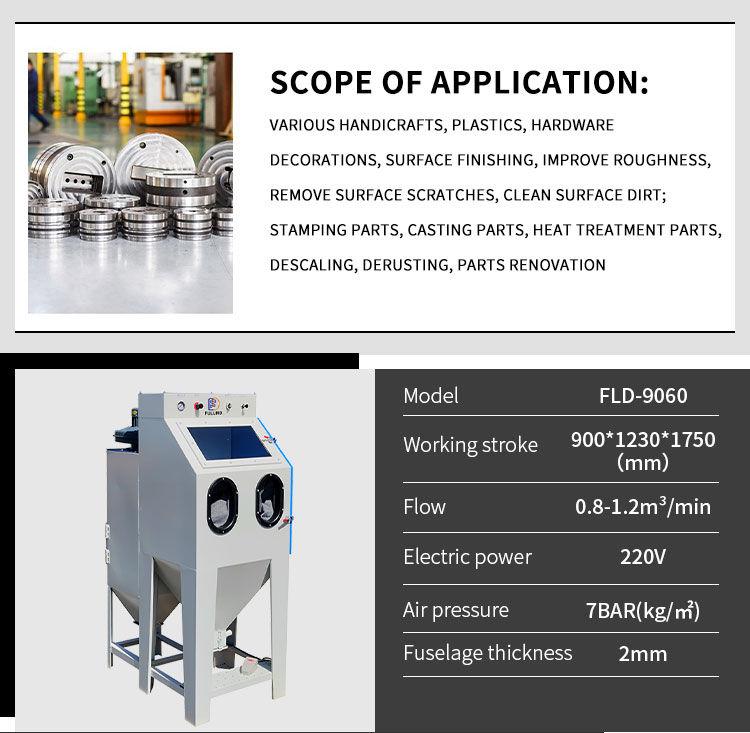

| Package preview: | Type of machine: | Sandblasting machine | |

| Core component warranty: | 1 year | Core components: | engine |

| fuel: | electrical | Packaging Details: | wooden box |

| Warranty: | 1 year | Weight (kg): | 0 |

| port: | Yantian | Supply capacity: | 200 sets per month |

| Applicable industries: | Manufacturing plants, machinery repair shops | Cleaning process: | wash in cold water |

| Video shipment inspection: | if | Mechanical test report: | if |

| strength: | 0 | Showroom location: | not any |

| cleaning type: | manual | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Material: | metal/coil | Health status: | new |

| brand: | Furlong | Dimensions (L*W*H): | 900*1230*1750 |

| Marketing Type: | New Products 2022 | Origin: | Guangdong, China |

| Main selling points: | low maintenance cost | use: | polishing |

Advantages of small manual sandblasting machine:

1. The machine is novel in design and easy to operate

2. Good processing efficiency and low sand consumption

3. Automatic sand return function, the cyclone separator separates the dust and sand particles of the sandblasting machine, reducing the consumption of abrasives (it can be installed as required)

4. This machine adopts automatic bag dust removal system, with high dust removal rate, no dust in the workshop, and environmental protection and sanitation

5. The main components such as pressure regulating valve, filter, solenoid valve and foot switch are all made of high-quality brands, with long service life.

6. The spray gun nozzle adopts boron carbide and tungsten hard nozzle, which is durable

7. Adopt special thickened high-pressure sand pipe and air pipe, which has strong wear resistance

8. This machine adopts a special medium-pressure fan for low-noise sandblasting machine, with low noise

9. The sandblasting gun is made of aluminum alloy die-casting, and the boron carbide nozzle is durable, and it is not tired when sandblasting.

10. The window is made of toughened glass, which is not easy to break

Scope of application:

Prototype factory, mobile phone refurbishment factory, mold factory, lighting factory, glasses factory, watch factory, jewelry factory, electronics factory, sandblasting oil factory, electroplating factory, oxidation factory, various handicrafts, plastics, hardware decorations, surface treatment, improvement Roughness, removal of surface scratches, cleaning of surface dirt; stamping parts, castings, heat treatment parts descaling, rust removal, parts renovation; matte and glossy decoration, all metal hardware products, glass, plastic products, decorative crafts, glasses frame, watch surface treatment, etc.

-

BY-1212 wet sand machine steam explosion machine wet sand blasting cabinet water steam machine

-

BY-1450-2A High-pressure sandblasting machine cleaning steel plate sandblasting machine

-

Manual Mini 100L/200L Sandblasting Tank Steel Shot Blasting Machine

-

Dust-free water blasting machine wet blasting machine blast tank DB 500

-

Micro dust-free sandblasting machine and dust-free sandblasting machine

-

Rust and paint removal wet sandblasting machine

-

CE certified multifunctional sandblasting machine

-

Portable industrial sand breaker

-

Sandblaster Machine Sandblasting cabinet SBC1000

-

220L Sandblasting Cabinet Abrasive Sandblasting Machine

Other Products

-

$100.00 / set

$100.00 / set -

$155.00 / set

$155.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set -

$500.00 / set

$500.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set