K tig welding with deep penetration

-

Supplier: Anyang Xinsheng Machine Tool Co., Ltd. -

Region: Henan, China -

Contact: Mr peter shu -

Price: $60000.00 /unit -

Min. Order: 1 unit

| Health status: | new | brand: | generic drug |

| Supply capacity: | 30 units per month | Packaging Details: | wooden box |

| Output polarity: | AC/DC TIG welding | Origin: | Henan, China |

| Arc current: | 50500A | maximum. Load power capacity: | 0 |

| payment terms: | L/C, T/T | Voltage: | 380V |

| type: | Argon arc welding equipment | aspect: | 820*530*1000 |

| color: | blue | Certification: | ISO9001 |

| After-sales service provided: | Online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support, engineers can provide overseas service machinery | Power factor: | 0.92 |

| Material/Metal Processing: | Stainless steel | Rated input voltage: | 0 |

| Nominal Duty Cycle (TIG) at 40°C: | 0 | Nominal Duty Cycle (%): | 500A @ 92% |

| Pulse frequency: | 50 Hz | Warranty: | 1 year |

| port: | Xingang, Qingdao, Guangzhou | strength: | 18.5kw |

| Motor type: | DC | Function: | keyhole needle |

| Nominal Duty Cycle: | 100% | Application products: | Tank Boiler Fermentation Tank |

| Arc current: | 50-700A | efficiency: | 100% |

| usage: | stainless steel welding |

Applications

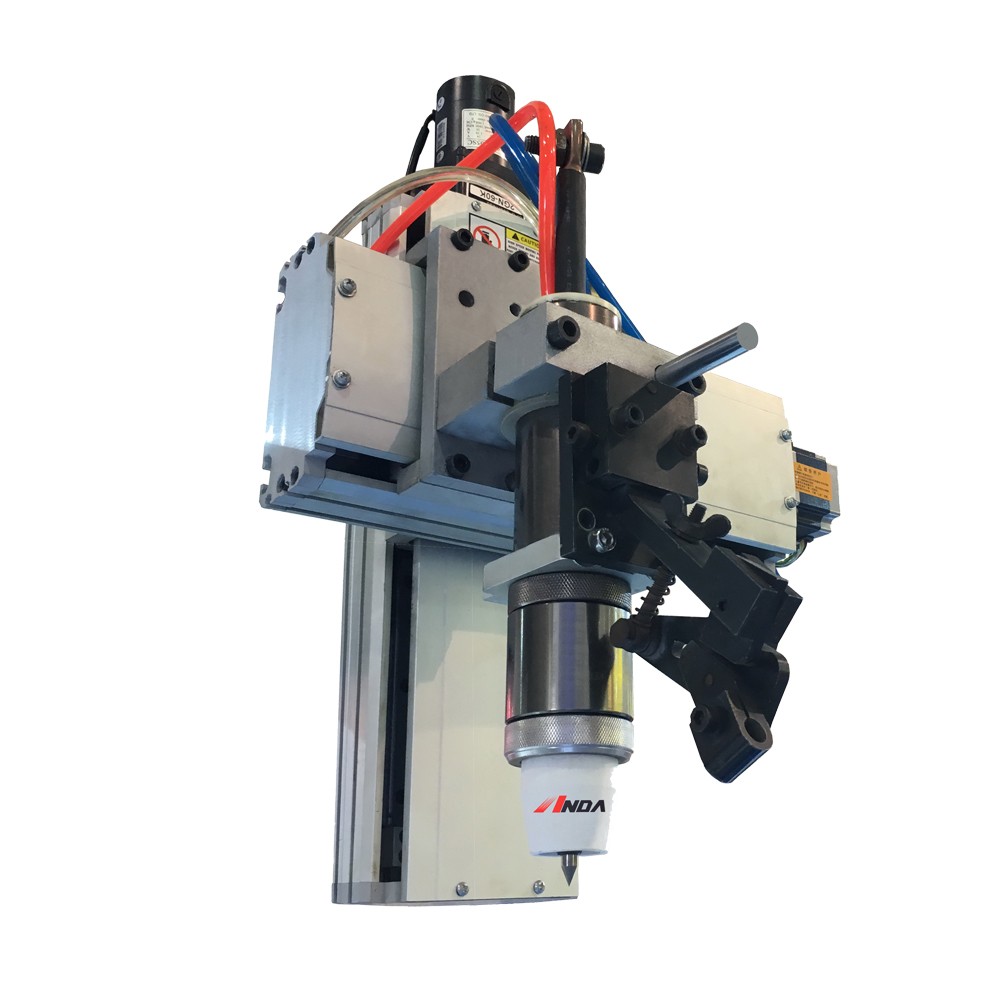

K-TIG welding is a new method that can achieve "keyhole" welding. It has the appearance of ordinary TIG welding, but also has the characteristics of super penetration depth of plasma welding.

K-TIG welding technology is a high-speed one-way full-penetration welding technology, it does not need any welding wire, no beveling, and no professional workers, but it can weld 10 times faster than ordinary TIG welding technology3 ~16mm thick plate (such as titanium alloy). (Note: Less than 3% of the welding material used in traditional welding is used to overcome occlusion.) 100% of the weld is the parent layer, no multiple fusion lines, no slag inclusions, pores and common weld defects. The waviness-free weld pool of K-TIG welding guarantees high quality covering both layers, completely eliminating the need for backlash and surface finish cleaning and polishing.

The K-TIG welding machine is equipped with a special welding torch based on the keyhole effect of the TIG welding machine control system. The computer system accurately calculates the welding material, thickness, and process parameters to achieve precise control of the welding process, so as to realize the automation of welding operations. Through computer programs Dynamically adjust welding parameters to ensure repeatable high welding quality.

K-TIG welding system can save a lot of manpower, material resources and energy for many welding applications. Suitable for welding stainless steel, nickel-based alloys, titanium alloys, zirconium alloys, cobalt alloys, etc. These expensive metal processing have high requirements on weld quality and shape, K-TIG welding can provide high welding quality and efficiency; at the same time, the quality, efficiency and cost advantages of thick plate welding are superior to other technologies. Therefore, it is more competitive than conventional welding and GMAW.

Project unit type: KTIG-500

Power input (V)/frequency (Hz) V/HZ three-phase 380 ± 10 % / 50Hz

Rated output (KW) KW 18.5

Rated input current (A) A 35

Output no-load voltage (V) V 12±3

Output current range (A) A 50-500

Rated Duty Cycle ( %) % 100

Full load efficiency (%) % 92

Power factor (full load) 0.88

Gas pre-time (S) S 0.1-15

Strike current (A) A 50-160

Ramp time (S) S 0.1-10

Decay time (S) S 0.1-15

Arc extinguishing current (A) A 50-160

Gas delay time (S) S 0.1-15

Weight (kg) KG 100

Dimensions: L x W x H (mm) MM 820x530x1000

main feature

K-TIG welding machine is a new type of high-efficiency and energy-saving inverter TIG welding machine that can realize stable automatic welding. Has the following advantages:

1. Automatic welding process

2. The operation is simple, and the workers can operate independently after 2 days of training

3. Fast welding speed, 5-10 times faster than ordinary TIG/GTAW

4. The welding machine workpiece does not need chamfering under a certain thickness, one side is welded and two sides are formed, the weld seam is good, no chamfering is required

5. The width of the back weld is 2 to 3 mm, and the width of the surface weld is usually about 1.5 times the thickness of the plate

6. Single-sided welding and double-sided molding, no need for chamfering, no need to add materials to achieve projection welding, and double-sided coverage

7. Strong fault tolerance, under a certain thickness, the gap between welding machine workpieces can reach 2mm

8. Welding carbon alloy steel, stainless steel, titanium alloy, nickel-based alloy, cobalt alloy, zirconium alloy, can guarantee excellent welding speed and quality

9. The best choice for thick plate welding, 12mm thick carbon alloy steel plate, 13mm thick stainless steel plate or nickel-based alloy plate and 16mm thick titanium alloy plate, cobalt alloy plate or zirconium plate. A "V" shaped groove should be opened above

10. The process is protected by pure argon

11. High welding efficiency and low energy consumption

12. Low maintenance cost

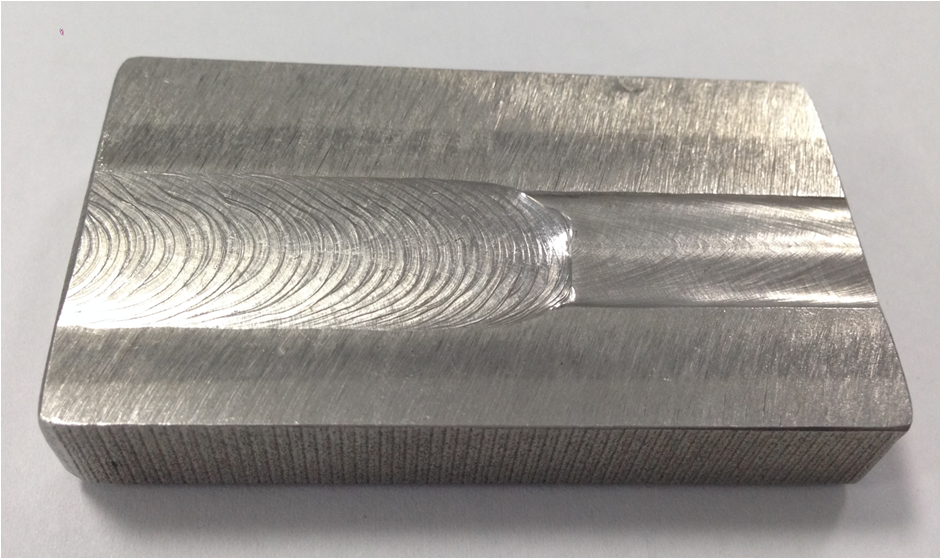

longitudinal seam welding

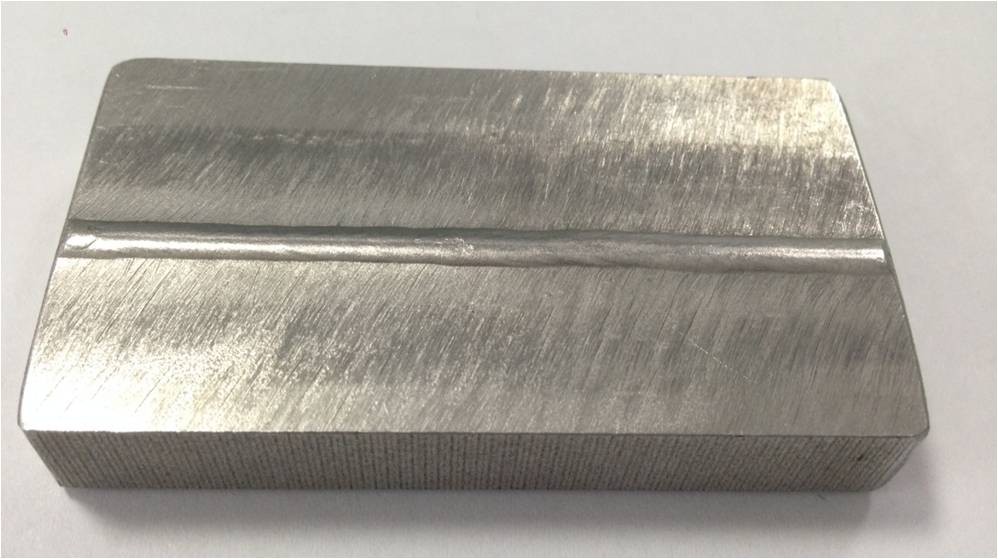

Girth welding

Stainless steel

Stainless steel back molding

-

ANDELI new product Tig-250MPC 4IN 1 Mig TIG lift tig clean welding machine

-

Andre 6-in-1 MIG, CUT, TIG, cold, MMA aluminum welding machine multifunctional welding machine specially designed

-

JONE inverter AC/DC pulse field effect tube argon arc welding machine AC and DC welding machine argon aluminum argon arc welding machine

-

SANYU TIG-315P TIG-315PW AC/DC argon arc welding machine aluminum argon arc welding machine

-

110V/220V TIG WelderARC TIG 2 in 1 Welder140Amp Stick MMA IGBT Smart Inverter

-

HITBOX AC aluminum welding machine HBT250P ACDC professional TIG pulse MMA ARC inverter welding machine 2T 4T semi-automatic control function

-

Multifunctional 5 in 1 plasma cutting machine ac dc tig mma pulse welding machine

-

ANDELI new product TIG-250PE TIG aluminum welding machine hot sale HF/LIFT TIG/Pulse/MMA/AC DC multifunctional welding machine

-

Ideal for welding aluminum and stainless steel TIG welder TIG-200P AC/DC

-

EDON maquina de sodar 110/220V dual voltage tig 200 ac dc inverter aluminum TIG welder