Ring die organic waste compost granulator

-

Supplier: Harbin Dadi Biology Organic Fertilizer Co., Ltd. -

Region: Heilongjiang, China -

Contact: Mr Wang Yanwen -

Price: $22000.00 /set -

Min. Order: 1 set

| Origin: | Heilongjiang, China | Voltage: | 380v (optional) |

| Dimensions (L*W*H): | 4.7*1.9*1.6m | Warranty: | 1 year |

| feature: | automatic | product name: | Organic Waste Composter |

| Core component warranty: | 1 year | Output shape: | small ball |

| payment terms: | wire transfer | Marketing Type: | New Products 2020 |

| Main selling points: | high productivity | weight: | 3500 kg |

| brand: | the earth | port: | Dalian |

| Showroom location: | not any | After-sales service provided: | Engineers available to service machinery overseas |

| Core components: | PLC, gearbox, motor | Packaging Details: | Organic waste compost machine packaging: steel frame wooden box or container |

| Mechanical test report: | if | Input material granularity requirements: | 0.3-0.5mm |

| Video shipment inspection: | if | capacity: | 3 tons per hour |

| application: | Organic fertilizer, waste recycling | Health status: | new |

| Applicable industries: | farm | Production capacity: | Minimum 90% |

| Moisture reduction after granulation: | 3% | Supply capacity: | 20 sets per month |

| Enter desired moisture content: | 30-35% | Package preview: |

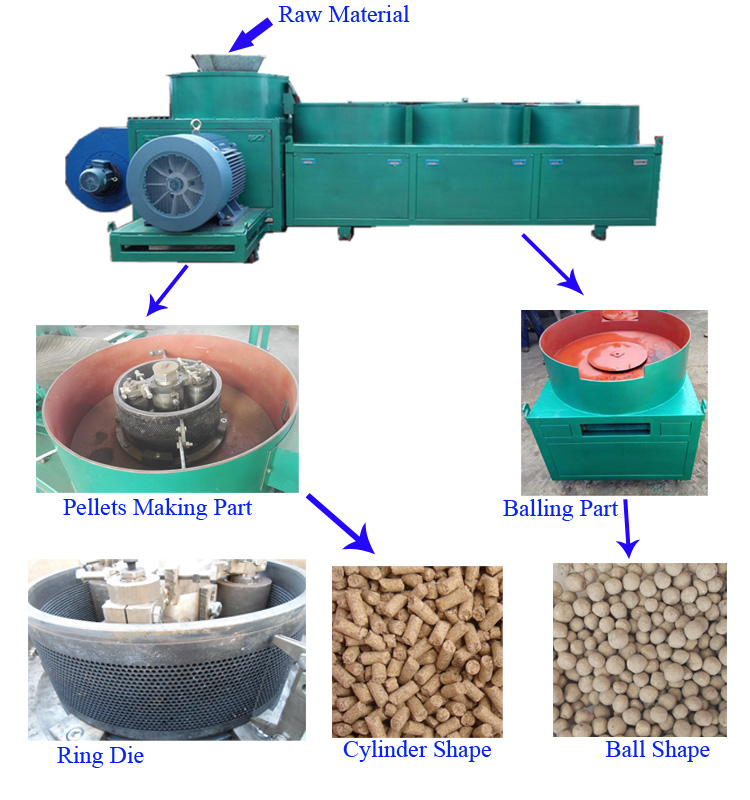

Ring die organic waste compost granulator

Ring mode organic fertilizer granulator is a new and improved granulator, which is specialized in manufacturing organic fertilizer granules. The moisture content of the incoming raw materials can reach 30-40%, and no dust escapes during the granulation process in a closed space. The fan design makes the surface of the granules dry and prevents the granules from sticking together. The extrusion process ensures that the pellets are sufficiently strong and uniform in shape. Polisher components turn cylindrical particles into spherical shapes. The good product rate is above 90%, and the finished product is spherical. It has uniform particles, good solubility, high purity and quality.

advantageOrganic Waste Composter:

1) All ingredients can be made into balls.

2) The minimum yield rate is 90%

3) The surface of the particles is smooth, the hardness is good, and it is not easy to break.

4) The content of organic matter can be as high as 100%, and it can be made into pure organic matter particles.

5) There is no need to add binders during granulation.

raw material

The organic waste composter can make the following raw materials into granular form:

1) Turf, lignite, sludge, pond sludge, bagasse, starch slurry.

2) Chicken manure, duck manure, pig manure, sheep manure, deer manure, cow manure, vermicompost.

3) Bean cake, vinasse, biogas residue, pomace, palm oil residue.

4) Municipal garbage or residues from sewage treatment plants.

5) Organic material mixed with mineral material.

How does the organic waste composter work?

The organic waste composter is divided into two parts:

1. Granulation part

Granule section with ring die and roller system:

The raw material enters the working chamber and falls on the "discharging tray", and the raw material is thrown into the ring die under the action of centrifugal force; the ring die and roller system are driven by reduction gears and transmission devices, and the energy comes from the motor. The pressure comes from the operation of the ring die and the roller system, and the cylinder is forced to be extruded from the hole of the ring die, and cut into the required small particles by the cutting line.

2. Pilling part:

The particles fall on the disc in the drum, and are thrown to the drum wall by the high-speed rotating disc in a circular motion. While the particles are doing circular motion, they also rotate radially due to centrifugal action. Due to the movement of the particles, the mutual friction makes the angular particles gradually become balls. At this time, the pellets gradually float on the top, and finally the pellets overflow as the amount of pellets in the drum increases.

Technical ParametersOrganic Waste Composter:

| Model | KHL-600 |

| Capacity: T/h | 2.5-3.5 |

| Enter desired moisture content: % | 30-35 |

| Moisture reduction after granulation: % | 3 |

| Required feed size: mm | 0.3-0.5 |

| Yield:% | >90 |

| Voltage: V | 380 |

| Particle size: mm | 3.5-5.5 |

| Power: KW | 64.5 |

| Total weight: Kg | 3500 |

| Size: m | 4.7*1.9*1.6 |

| LCL | FCL | |

| Way | Steel frame wooden box | container |

| packaging details | The normal packing is wooden case (size: L*W*H). If exported to European countries, wooden boxes will be fumigated. If the container is too tight, we will use pefilm for packaging or according to customer's special requirements. | containerized |

1. Design the production line for you.

2. Design the factory layout according to your requirements and factory scale.

3. Sample test support.

4. Provide comprehensive technical and business consulting services.

5. Fast and safe delivery.

6. Training how to install the machine, how to use the machine and maintenance.

7. Engineers who can repair machinery overseas.

You can enjoy all-round one-stop services such as drawing design, equipment construction, installation and operation provided by us.

-

Fast fermentation goose manure pig manufacturer direct sales mobile compost turning machine

-

Cost of High Quality Wholesale Customized Cheap Cow Dung Organic Fertilizer Machine Factory in India

-

Fermentation bed compost turning machine (whatsapp: 008618137186858)

-

Agricultural machinery wheeled compost dumper in organic fertilizer manufacturing

-

Automatic Biochar Fertilizer Organic Pellet Machine

-

Batch Mixer Single Shaft Mixer / Clay Mixer

-

Compost turner for mature manure from animal manure

-

Tractor Pulled Composter / Composter Price

-

Commercial Compost Turner Manure Fermentation Compost Machine Organic Compost Granular Fertilizer Making Machine

-

Chicken manure compost tank/compost dumper

Other Products

-

$42000.00 / set

$42000.00 / set -

$15000.00 / set

$15000.00 / set