Hot sale 1000w 1500w 2000w handheld laser welding machine laser welding machine price portable laser welding machine

-

Supplier: Wuhan Hongmeng Laser Technology Co., Ltd. -

Region: Hubei, China -

Price: $1500.00 /set -

Min. Order: 1 set

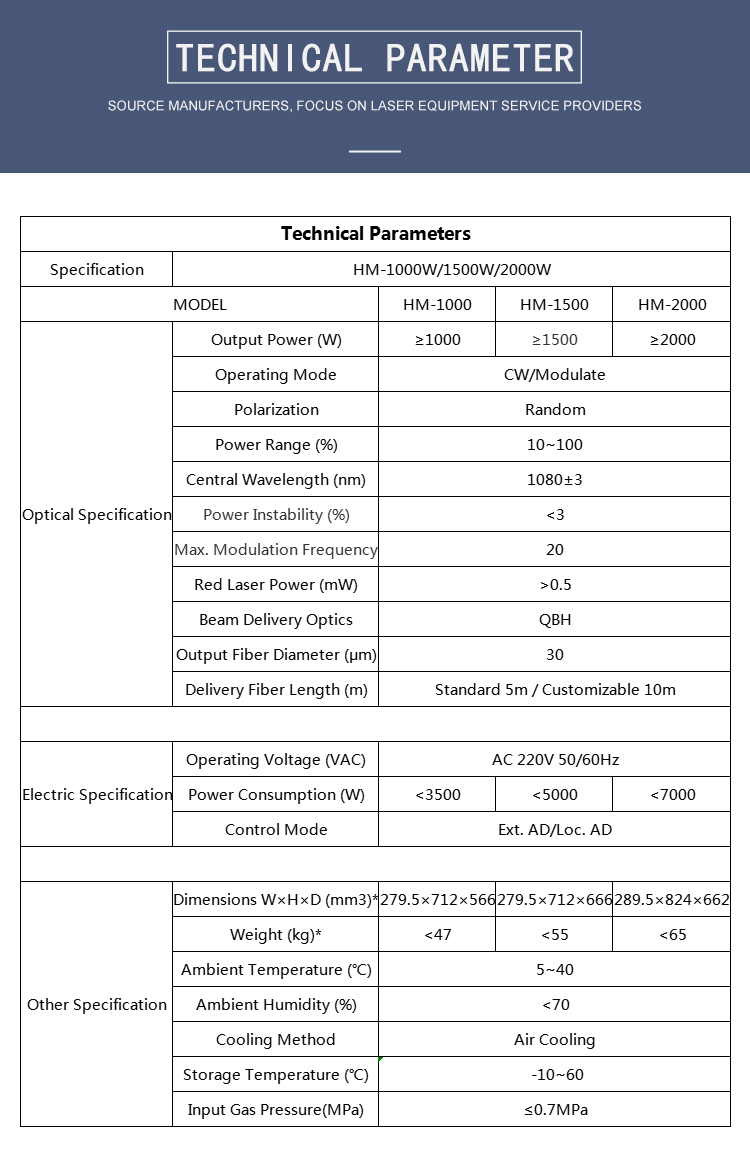

| Video shipment inspection: | if | Laser source brand: | Raycus |

| Welding speed range: | 0-120 mm/s | Marketing Type: | New Products 2020 |

| aspect: | 1300X650X1100mm, 1300X650X1100mm | Main selling points: | high rigidity |

| Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies | Laser device: | 1000W/ 1500W / 2000W |

| Water cooling: | For handheld welding | Core component warranty: | 1 year |

| Origin: | Hubei, China | Core components: | motor, bearing |

| maximum. Output Power: | 2000W | Package preview: | |

| usage: | laser welding machine | payment terms: | L/C, T/T |

| Fiber Length: | Standard 15m | Warranty: | 1 year |

| Electromechanical: | 380V/50HZ or 220V optional | Total power: | 6KW |

| wavelength: | 1080nm | Health status: | new |

| Laser wavelength: | 1080nm | Mechanical test report: | if |

| Weight (kg): | 150 kg | gross weight: | 150KG |

Hand-held fiber laser welding can be used for welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, and can also be used for welding between a variety of different materials, such as: copper-brass, titanium- Gold, titanium-molybdenum, nickel-copper, etc.

Welding range: carbon steel 0.5~8mm, stainless steel 0.5~4mm, aluminum alloy 0.5~6mm, brass 0.5~4mm.

main features

1. The system is mainly composed of laser unit and welding unit.

2. Hand-held welding, taking into account the flexibility, high efficiency and high weld quality of laser welding.

3. The modular design layout of the overall equipment is beautiful and easy to maintain and debug.

4. The system is highly flexible, compatible with various models, and the switching time is short.

5. The internal design is smart, and the good interactive control system expands the tolerance range of the processed parts and the width of the weld seam, which solves the shortcoming of small light spots, and the weld seam is better formed.

6. The appearance is light and handy, adopting the engineering design method of the fuselage, with a comfortable grip; easy to control by hand, and easy to operate.

7. It has multiple safety alarm functions, and automatically locks the light after the workpiece is taken out, which is highly safe.

8. The welding seam is beautiful, the speed is fast, no consumables, no welding marks, no discoloration, no need for post-grinding.

9. It can be equipped with multiple angle nozzles to meet the welding needs of different products.

1. Delivery time:

Lead times are 7-15 days for standard machines and 15-30 days for custom made machines to customer specifications.

2. Payment terms:

Pay 30% deposit after accepting quotation and 70% invoice balance before shipment. T/T, Western Union are the approved payment methods.

3. Transportation:

Goods can be shipped by any of the following methods: FOB or CIF by our shipping partners. For EX.W, ship by you or your agent.

4. Machine operation instructions:

The following options are available to customers: Instructional videos demonstrating how to use the machine. Free training sessions at our factory, subject to availability. The machine comes with an operator's manual (in English).

5. Warranty and after-sales service:

The machine comes with a 12-month warranty. 24 hours free technical support service via email, fax, MSN, Skype, telephone, tradeMessenger.

6. Product Warranty:

During the warranty period, replacement parts will be provided free of charge. After the warranty period expires, the cost of replacement parts shall be borne by the customer. However, we guarantee customer support within 48 hours of notification of a problem to support product maintenance.

7. Minimum order quantity (MOQ):

We accept single (1) machine orders.

-

New 4 in 1 handheld 700W 1500W 2000W laser welding machine with air cooling Raycus laser source gear core components

-

IPG LightWELD 1500XC Mini Air Cooled Handheld Fiber Laser Welding Machine

-

2023 New 1000W 2000W 3000W Small Handheld Metal Welding Laser Machine

-

Kirin V10 handheld fiber laser welding spare parts soldering iron welding machine welding head 2000w double swing

-

Cutting+welding+cleaning machine 1500w fiber laser welding system 3 in 1 metal welding machine

-

Laser Welding Machine 3000W Twin Wire Wider Weld Seam Stronger Cladding Surfacing Fast Welding Laser Machine 8mm Steel Fully Welded Once

-

Yag Spot Laser Welding Machine 100W 200 Watts Portable Jewelry Welding Machine

-

Boom Type High Speed Metal Laser Mold Welding System Laser Welding Machine

-

Handheld Laser Welding Machine China manufacture

-

200w gold and silver YAG fiber laser welding machine desktop jewelry laser welding machine

Other Products

-

$600.00 / piece

$600.00 / piece -

$850.00 / piece

$850.00 / piece -

$1200.00 / piece

$1200.00 / piece -

$290.00 / piece

$290.00 / piece -

200W Portable Jewelry Gold and Silver Mini Laser Welding Machine Price Jewelry Laser Welding Machine$500.00 / piece

200W Portable Jewelry Gold and Silver Mini Laser Welding Machine Price Jewelry Laser Welding Machine$500.00 / piece -

$1000.00 / bag

$1000.00 / bag -

$389.00 / piece

$389.00 / piece