Advanced technology, high quality and low price ceramic thermal fuse

-

Supplier: Ningbo Meya Electronic Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Anne Lee -

Price: $0.07 /piece -

Min. Order: 1 piece

| current: | 10A/250V | Case 2: | Metal |

| Case 1: | plastic | Breaking capacity: | High |

| Package preview: | port: | Ningbo | |

| safety standard: | CE, VDE, ROHS | Origin: | Zhejiang, China |

| lead: | 70mm or according to customer requirements | brand: | AB |

| model: | RH thermal fuse | Packaging Details: | export carton |

| payment terms: | Western Union, T/T, Paypal | Supply capacity: | 300,000 pieces per day |

| usage: | car |

158C RH hot link

Specification:

1. Rated voltage: 250V, AC and 125V

2. Rated current: 10A and 16A

3. Frequency: 50 or 60Hz

4. Maximum allowable power: 250V, AC16A

Rated temperature range

| Model lat | task force | Table of contents | TH C | TMC | rated current | Rated voltage | certified |

| RH-3-200 | 200 | 195+/-5 | 150 | 280 | 10A | 250V | TUV CB CCC |

| RH-3-230 | 230 | 225+/-5 | 180 | 280 | 10A | 250V | TUV CB CCC |

| RH-3-240 | 240 | 235+/-5 | 190 | 280 | 10A | 250V | TUV CB CCC |

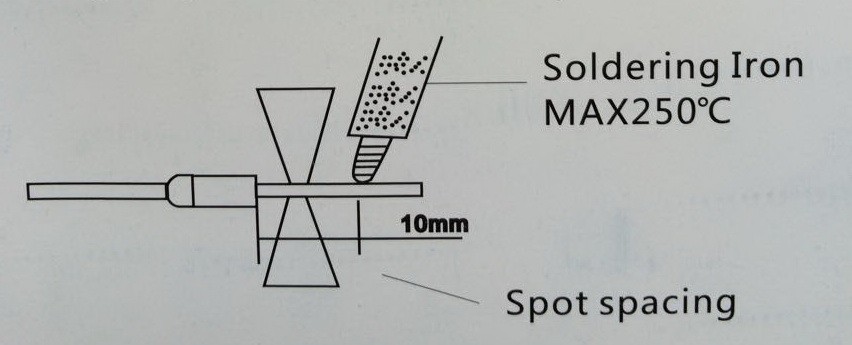

Welding of down lead

It is best to solder away from the fuse, at least 10mm away from the tube. When soldering, the heart transfer on the fuse tube should be minimized. In order to reduce soldering time, it is best to solder tin where soldering is required. The mechanical strength of the lead connection should not depend solely on the solder.

feature

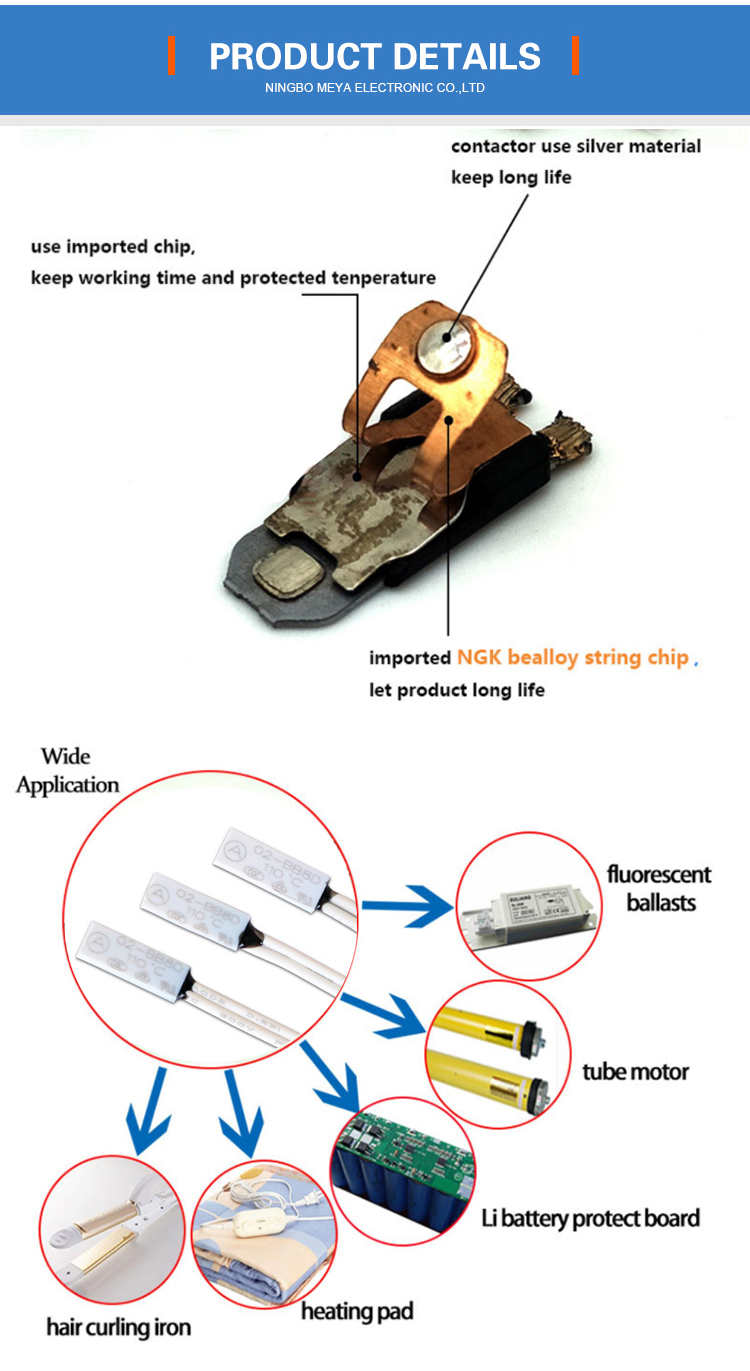

The product has the ability to cut off the circuit immediately with high current, and it is non-recoverable.

The thermal fuse itself has low internal resistance, small size and easy installation.

The product is sensitive to external temperature, and has high working temperature accuracy and stability.

application:

Products are widely used in refrigerators, electric irons, electric ovens, microwave ovens, rice cookers, coffee machines, hair dryers, sandwich ovens, electric tools and various household appliances.

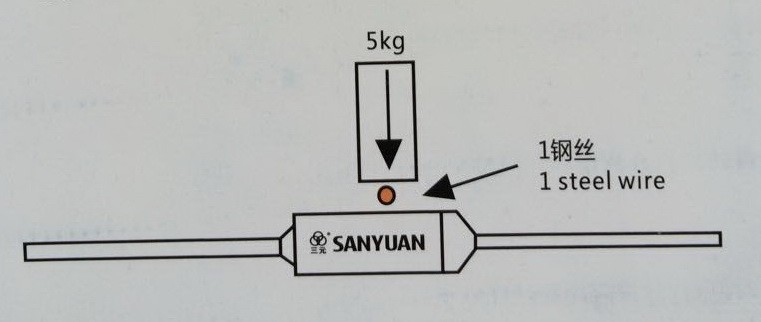

Mechanical strength:

The pressure acting on the shell shall not exceed 5kg, and it shall not exert too much impact on the body. Note that the thermal fuse body shall not be subjected to a large impact.

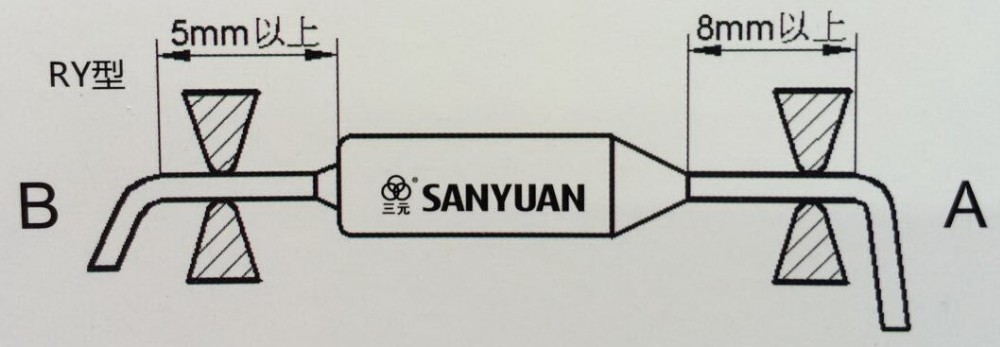

Install:

Pay attention to the short circuit of the epoxy resin when installing, for example, avoid the contact of lead A with the case, otherwise the current will flow from the lead on the side of the epoxy seal to the lead on the opposite side, so the hot link cannot break the circuit.

The organic thermal fuse link is a live device, the shell must not be in contact with other metal mounting parts, and the surface is protected by insulation.

When bending the leads on the epoxy side, bend them or over distance. The pull and push forces applied to the leads shall not exceed the test forces required by IEC 60691. The maximum test tension series of thermal image RY is 16N, and the maximum test thrust is 4N.

Also, when securing the thermal link, take care not to apply excessive force (such as pulling, over-tightening, or over-clamping) to the housing, epoxy seal, or leads, which may damage the performance of the thermal link.

When installing leads, never pull, push, twist at sharp angles, or burn. Take care not to damage, burn, or overheat the epoxy seal or case.

Storage:

The main body and lead A of the thermal link RY series are silver-plated, improper protection will lead to vulcanization and discoloration. In this case, the marking on the body will become difficult to recognize or the welding ability of the lead will be reduced. To avoid this, it is not recommended to store the heat pipe directly in an enclosure made of a material such as cardboard or leather that produces sulfur gas.

-

Low voltage DC fuse A070UD31LI800 F300707 fuse 690V 800A electronic components

-

100 Pieces Automotive Blade Fuse Assortment Kit, Standard/Mini Auto Fuses 1-40A, Automotive Assortment Fuses with Puller

-

Photovoltaic DC fuse 1000V 10*38mm protection solar system fuse holder 30A OEM electrical safety low voltage base thermal fuse waterproof

-

Fuse connection 1A 2A 3A 4A 5A 6A 7A 8A 10A 12A 15A 20A 25A 30A 35A 40A 50A 60A 65A 75A 80A 100A 120A 200A Connection 3V 11

-

Competitive price NH fuse disconnect switch for switchboard

-

Bolt-on Bolt-down ANL ANM ANS Fuses 25A 40A 50A 60A 70A 80A 100A 125A 150A 175A 200A 250A 300A 350A 400A 450A 500A

-

Professional artillery fire engineering combination roll fuze rope

-

Brand New Auto Spare Parts Positive Battery Cable Bracket Fusible Fuse Connector OEM 24380-79915 2438079915

-

Wiper Blade Universal Windshield Wiper Quality Assurance Silicone Strap 11 Adapter Car Rubber Car Wiper Blade High Black

-

20A 25A 30A 35A 40A 50A 60A 70A 80A 100A 150A 200A 250A 300A 350A 400A Automotive PPTC ANL Fuses

Other Products

-

$0.21 / piece

$0.21 / piece -

$0.04 / piece

$0.04 / piece -

$0.05 / piece

$0.05 / piece