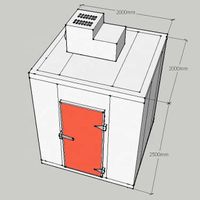

CBFI rapid cooling fridge freezer cold storage room for food

-

Supplier: Guangzhou Icesource Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Emily Yan -

Price: $1200.00 /set -

Min. Order: 1 set

| 3.Control system: | Full automatic control system; | Temperature: | All kinds; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service; | Port: | Guangzhou port; |

| 1.Temperature range: | -60℃ to +20℃; | 8.Refrigeration unit: | Copeland, Bitzer, Hitachi, Franscold and others; |

| Weight: | as customers requirement; | 6.Size of door: | As your demand; |

| 2.Size: | Customize; | Warranty: | one year; |

| Condition: | New; | Supply Ability: | 300 Square Meter/Square Meters per Week cold room; |

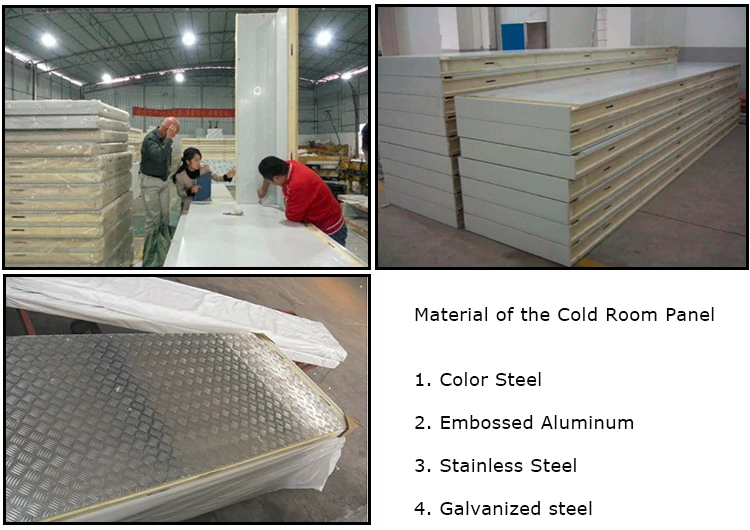

| Packaging Detail: | 1. Standard wooden case for machine unit of cold room. 2. Bubble film and paper corner for cold room panel. Cold room insulation panels: A.embossed aluminum plate B.Stainless steel plate C.Color zinc plate D.The monitoring of the steel plate E.Galvanized sheet; | Certification: | CE; |

| Brand Name: | CBFI; | 4.Control box: | Digital indicator; |

| Power(W): | as customers requirement; | Voltage: | 380v/50hz/3ph or 220v/60hz/3ph; |

| 5.Type of door: | Sliding door/Swing door; | Payment Terms: | L/C,T/T,Western Union,in cash; |

| 10.Insulation material: | Polyurethane (PU); | Place of Origin: | Guangdong China (Mainland); |

| Dimension(L*W*H): | Customized Size; | 7.Cooling way: | Air cooling, water cooling; |

| 9.Local power supply: | 380V or 220V, Single phase or triphase, 50Hz or 60Hz; |

Cold Room

Cold room are widely used in food process factory, dairy factory, pharmaceutical factory, chemical factory, fruit and vegetable warehouse, egg storage, hotel, supermarket, hospital, blood bank, troops and laboratory.

Cold room has the following features:

1. Nice appearance : The insulation panel and framework are available in dozens of colors which are to be elected in satisfactory harmony with various styles of buildings.

2. Insulation : Polyurethane or polystyrene with low thermal conductivity and high strength is utilized, achieving good insulation performance.

3. Short construction period

4.Fast installation

5. Hygienic conditions of food inside cold stores are up to the standards.

6. Durable building structure, super quality material

7. Temperature:-20°C~-30°C or -10°C~-18°C or 8°C~-5°C

8. Size: Customization

Cold Room Panel Features

1: Rigid polyurethane has low thermal conductivity and good thermal performance. Density

of rigid polyurethane is 38~42kg/m3, which is the lowest thermal conductivity in the thermal

insulation material.

2: Polyurethane cold panel has good performance of moisture-proof and waterproof, and belongs to the hydrophobic material.

3: Cold polyurethane panels have fire-proof, flame retardant, heat-resistant. It will not produce harmful gases at high temperature.

4: Polyurethane cold room panel has strong anti-deformation, uneasy to crack, and its surface is stable & safety.

5: Polyurethane cold panel has light weight, easy to disassemble and assemble, easy to use.

Cold room panel

Cold chamber panel, size, and temperature:

Thickness | Suitable temperature |

50 | 5°C or above |

75 | -5°C or above |

100 | -28°C or above |

150 | -35°C or above |

200 | -45°C or above |

We have 3 kinds of materials with various thickness, and the application of the corresponding temperature. The standardized width of cold room panel is 1000mm and length can be

2000-12000mm.

Cold Room Door Features

1. Cold room door has the advantages of reasonable structure, no moisture absorption, no

rust, no deformation, light weight, good heat insulation, less land occupation and other

characteristics. It is the advanced, beautiful, ideal refrigerator door.

2. All cold room door can be customized according to customer requirements so that

ensure each door can perfectly meet customers' requirements.

3. Door has different type : single hinge Door, double hinge door, sliding door and electric

sliding door

Condensing uint

1.Compressor : We have different type of compressor brand for choice : Germany Bitzer ,

American Copeland , French Maneurop and Taiwan Hanbell.

2. Air cooler : The shell is made of quality steel plate; sprayed plastic surface is

anti-corrosive, and its appearance is handsomeCoiled pipes are mechanical expanding

tubes in staggered arrangement; therefore, copper tubes and aluminum sheets are combined

closely.

3. Electrical Controller Box

Just a start press, you can control the system automatically, without human operation. When

the room temp drops to the lower limit of the set temperature, the compressor and air

cooler will stop working automatically; When the room temp rises to upper limit of the

set temperature the compressor and air cooled will start to work automatically.

Product List:

| Tube ice machine | Block ice machine | Ball ice machine | Cold room |

| Cube ice machine | Flake ice machine | Nugget ice machine | Plate ice machine |

ABOUT US

Guangzhou Icesource Co., Ltd. (trademark CBFI), a pioneer in the large-scale fluorine refrigeration and ice making equipment industry, is an innovative and entrepreneurial high-tech enterprise that integrates research, design, manufacture, sales, and after-sales .The main products are block ice machine, tube ice machine, cube ice machine, flake ice machine, plate ice machine, cold room, intelligent cold room unit, ice machine supporting equipment and fully automated ice plant. Products are widely used in food, retail, fruits and vegetables, aquatic products, chemicals, medical, construction, minerals and other fields for cooling, storage and preservation.

The company was established in 2010, and the research and development started in 2004. Since the establishment of the company, it has continuously increased investment in product research and development. All sales products are independent research and development products. By April 2018, there were 2 invention patents, 21 utility model patents, 1 appearance patent, and 9 invention patents and 6 utility model patents are under examine and verify.

1.Q: are you add refrigerant in the ice machine?

A: yes, the machine is full of refrigerant, once with water and electric it can work. yes, ice machine leaves factory with carefully examination after it was produced for 3 to 5 days. And when we install them at customer’s factory, we retest the ice machines.

2.Q:do you test the ice machine in your factory?

A: yes, ice machine leaves factory with carefully examination after it was produced for 3 to 5 days. And when we install them at customer’s factory, we retest the ice machines.

3.Q: can you load ice machine into container?

A: we have containerized ice block machine. Our export ice machine is designed based on the standard of container, it is easily to load. The 25kg ice of 10tons can load in container of 40 feet. for domestic ice machine of over 12 tons per day, we design based on the standard of truck, which can easily drive into your factory.

4.Q: all your ice machine is based on 380V 50HZ power requirement? Do you have the right power requirement for abord? Such as 440V 60HZ or 220V three phase that suitable for America?

A: our ice machine and power,voltage can suitable for your country, please make the power requirement be clear in your order.

-

Freezer Refrigerator Meat/Fish Freezer

-

China supplier refrigerated container PU board fruit meat cold storage room

-

Pickup/refrigerated tricycle DC integrated refrigerator

-

Meat Seafood Beef Chicken Frozen Walk-in Pantry Walk-in Freezer Freezer Fish

-

DC Mini Portable Cold Storage Room Cold Chain Box for Refrigerated Truck / Refrigerated Truck

-

Fresh milk delivery electric refrigerated tricycle/ice cream truck/cold chain logistics

-

Cold storage door material Cold storage door for sale Cold storage warehouse door

-

Banana cold storage 40 feet, 20 feet container 15 degrees cold storage, greenhouse walk-in freezer

-

5MT- 10MT container freezer solar cold storage

-

Industrial cooling equipment of EMTH cold rooms for sale