Hot Selling Plastic Granule Manufacturing Process

-

Supplier: Zhengzhou Taizy Trading Co., Ltd. -

Region: Henan, China -

Contact: Mr Monica Chen -

Price: $3000.00 /set -

Min. Order: 1 set

| maximum. capacity: | 150-200kg | Core component warranty: | 1 year |

| Dimensions (L*W*H): | 2.6*0.7*0.7m | Material: | pvc |

| Certification: | ISO9001 | brand: | Taze |

| Mechanical test report: | not available | Origin: | Henan, China |

| Supply capacity: | 50 sets per month | type: | recycling granulator |

| Core components: | bearing | Video outbound inspection: | if |

| Showroom location: | not any | Applicable industries: | manufacturing plant |

| strength: | 10 kW | Output (kg/h): | 50 - 1000 kg/h |

| Plastic processing: | PE/PP, PP, PVC, PET, EPS | Warranty: | one year |

| weight: | 450 | port: | Qingdao Port |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Voltage: | 220 volts |

| Health status: | new | Packaging Details: | Manufacturing process of plastic particle wooden box |

| Marketing Type: | normal product | Screw design: | single |

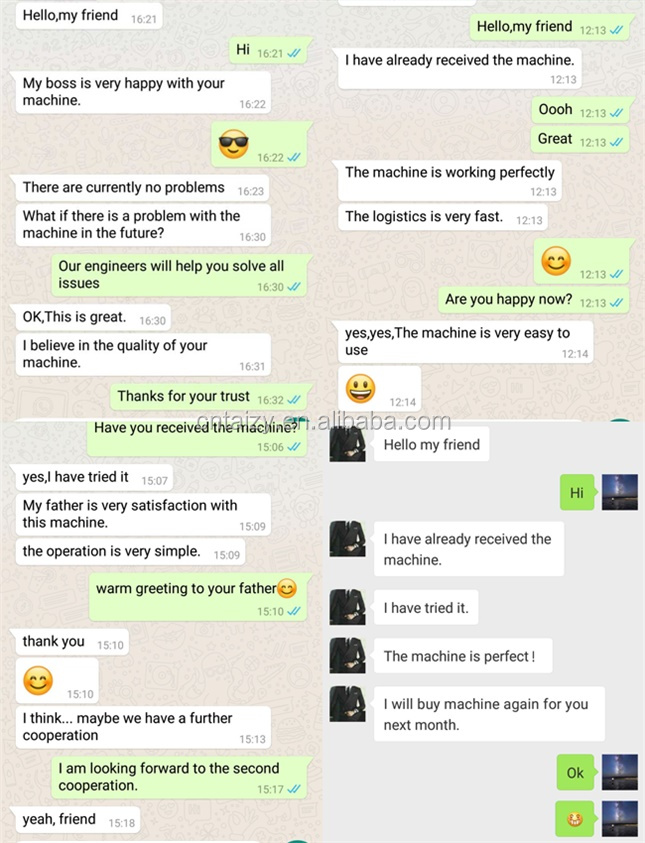

| After-sales service provided: | Engineers available to repair machinery overseas |

Plastic granulator/recycled plastic granule/primary plastic granule/plastic granule machine/plastic granule price/plastic granule manufacturing machine/plastic granule manufacturing process

Introduction to Plastic Pellet Manufacturing

1) The granulator consists of a conical twin-screw extruder

And the corresponding granulation auxiliary equipment;

2) Mainly suitable for PVC, PE PP, PE, PS, PC, PVC,

The raw material is wood flour or other granulation.

3) The particles produced by this machine are uniform, firm and beautiful.

4) The granulation auxiliary equipment adopts the die surface cutting and air delivery device,

Vibration separation and cooling unit.

5) The granulation auxiliary equipment has the characteristics of high degree of automation

And the production efficiency is high.

Manufacturing parameters of plastic pellets

|

Model |

Screw diameter |

Motor Power |

heating power |

capacity |

| Tianzheng-90 | 90 mm | 5.5 kW | 6 kW | 20-80kg |

| TZ-125 | 125 mm | 11 kW | 10 kW | 40-120kg |

| TZ-150 | 150mm | 18.5 kW | 15 kW | 100-200kg |

Advantages of plastic pellet manufacturing

1) Raw materials are cheap and easy to find.

2) The machine is easy to operate and easy to clean.

3) The finished product is widely used.

production line

-

Plastic granulation recycling line PE PP film granulator plastic film granulator granulator

-

Cheap price PP PE granulation plastic granulator granulator

-

HDPE PP ABS PE Recycled Plastic Pelletizer Plastic Pelletizer

-

Plastic granulator Pe water ring eager cutting granulator plastic granulator

-

TL100 waste plastic film granulation concentrator granulation recycling

-

Pp Pe plastic woven bag granulation production line granulation system

-

Factory direct sales waste granulation line plastic recycling machine granulator

-

ps recycled waste granulator extrusion LDPE granulator production line

-

SDHT plastic granulator recycling machine extruder granulator factory direct sales hot sale

-

Waste Plastic Film Agglomerator Densifier Machine For sale

Other Products

-

$1000.00 / set

$1000.00 / set -

$17000.00 / set

$17000.00 / set -

$900.00 - $1500.00 / set

$900.00 - $1500.00 / set -

$3000.00 / set

$3000.00 / set -

$2000.00 / set

$2000.00 / set -

$100.00 / set

$100.00 / set -

$2000.00 / set

$2000.00 / set