STR can customize solid wood and wood plastic flooring production lines and provide design solutions

-

Supplier: Xiamen Strongtech Co., Ltd. -

Region: Fujian, China -

Contact: Ms Vicky Hu -

Price: $268888.00 /piece -

Min. Order: 1 piece

Product details

| Crosscut saw cut: | 1.2~2.2 mm | Double end milling total power: | 29.25 kW |

| Automatic: | automatic | weight: | 17630 kg |

| Voltage: | 220/380/Customized | Main machines: | Four-sided planer, optimal saw, finger jointer, cross-cut saw, horizontal saw, double-end milling machine |

| Total power of four-sided planer: | 39.75 kW / 54 hp | Optimize the maximum saw feed speed: | 150 m/min |

| strength: | custom | Double-end milling spindle speed: | 6000 rpm |

| Mechanical capabilities: | custom | 4 Planer feed wheel diameter: | 140 |

| Optimize the maximum feed length of the saw blade: | 6500 mm | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Crosscut saw wheel diameter: | 800 mm | Optimizing saw blade extraction: | 2500 cubic meters/hour |

| Health status: | new | Dimensions (L*W*H): | 18000x15600x10020 mm |

| brand: | strength | Year: | 2024 |

| Origin: | Fujian China | 4. Planing thickness (mm): | 8-130 |

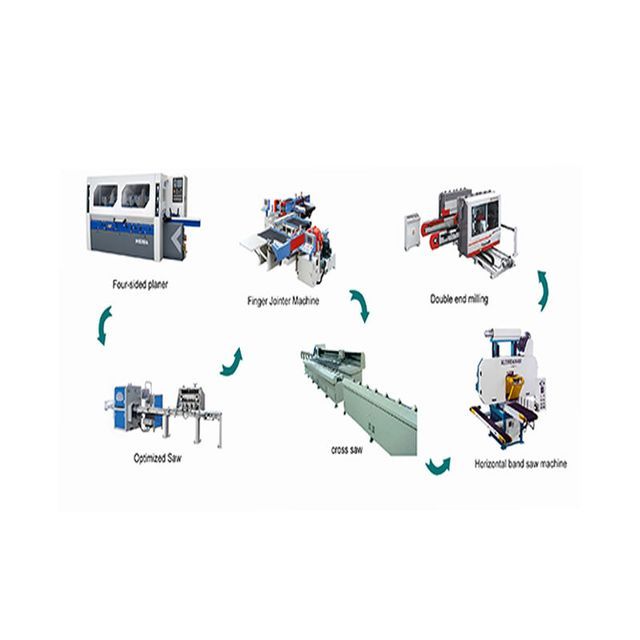

Wood flooring production line is applicable to: custom furniture, panel furniture, cabinets, wardrobes, office furniture. The machines required for this production line include: 1. Four-sided planer 2. Optimized saw 3. Finger jointer 4. Cross-cut saw 5. Horizontal saw 6. Double-end milling production line overview: The wood flooring production line is designed to meet the manufacturing needs of custom furniture, panel furniture, cabinets, wardrobes, and office furniture. It integrates a series of special machines that can efficiently process and shape wood materials to produce high-quality flooring and furniture components. Machine introduction: 1. Four-sided planer: A precision woodworking machine used to shape and sand all four sides of the workpiece to precise dimensions, ensuring uniform thickness and smooth surface. 2. Optimized saw: This machine is used to cut wood materials with high precision and efficiency, optimizing the cutting process to minimize waste and maximize material utilization. 3. Finger jointer: This machine is designed to form strong and seamless finger joints on wood pieces, which is essential for joining shorter pieces of wood together to produce longer and more durable wood pieces. 4. Crosscut Saw: Crosscut saws are used to make accurate, clean crosscuts on wood, ensuring precise, even cuts in a variety of woodworking applications. 5. Horizontal Saw: This machine is used to cut large boards and panels horizontally, providing precise, efficient cuts for the production of furniture components. 6. Double End Milling Machine: This machine is used to mill and shape the ends of wood pieces and is essential for achieving precise, smooth edges that aid in the assembly and finishing of furniture and flooring components.

Four-side planerReference Model

We can customize suitable products according to your needs. Reference parameters

M418A | M518A | M618A | |

Processing width(mm) | 25-180 | 25-180 | 25-180 |

Processing thickness (mm) | 8-120 | 8-130 | 8-130 |

Front workbench length (mm) | 1500 | 1500 | 1500 |

Feeding speed (m/min) | 6-36 | 6-36 | 6-36 |

Spindle diameter (mm) | φ40 | φ40 | φ40 |

Spindle speed (r/min) | 6200 | 6200 | 6200 |

Air source pressure (Mpa) | 0.6 | 0.6 | 0.6 |

First lower axis | 5.5 kW / 7.5 hp | 5.5 kW / 7.5 hp | 5.5 kW / 7.5 hp |

Right vertical axis | 5.5 kW/7.5 hp | 5.5 kW/75 hp | 5.5 kW/75 hp |

Left vertical axis | 5.5 kW/7.5 hp | 5.5 kW / 7.5 hp | 5.5 kW / 7.5 hp |

First upper axis | 7.5 kW/10 hp | 7.5 kW/10 hp | 7.5 kW/10 hp |

Second upper axis | 5.5 kW/7.5 hp | ||

Second lower shaft | 5.5 kW/7.5 hp | 5.5 kW/7.5 hp | |

Axis lifting | |||

Beam lifting | 0.55 kW / 0.75 hp | 0.55 kW / 0.75 hp | 0.75 kW / 0.75 hp |

Feeding | 4 kW/5.5 hp | 4 kW/5.5 hp | 4 kW/7.5 hp |

Total Power | 28.55 kW / 39 hp | 34.25 kW / 46.5 hp | 39.75 kW / 54 hp |

First lower axis(mm) | φ125 | φ125 | φ125 |

Right vertical axis(mm) | φ125-φ160 | φ125-φ160 | φ125-φ160 |

Left vertical axis(mm) | φ125-φ160 | φ125-φ160 | φ125-φ160 |

First upper axis (mm) | φ125-φ160 | φ125-φ160 | φ125-φ160 |

Second upper axis(mm) | φ125-φ160 | ||

Second lower shaft (mm) | φ125-φ180 | φ125-φ180 | |

Feed wheel diameter (mm) | φ140 | φ140 | φ140 |

Dust removal pipe diameter (mm) | φ140 | φ140 | φ140 |

Dimensions (mm) | Length 3250×Width 1550×Height 1720 | Length 3250×Width 1550×Height 1720 | Length 3750×Width 1550×Height 1720 |

Net weight/kg) | 3200 | 3300 | 3800 |

Air volume | 10500 cubic meters/hour | 10500 cubic meters/hour | 12200 cubic meters/hour |

Optimized saw

We can customize suitable products according to your needs.

Reference Parameters

Reference Parameters

Saw motor performance | 4 kW |

Minimum cutting height | 10 mm |

Maximum cutting height | 50 mm |

Minimum cutting width | 25 mm |

Maximum cutting width | 150 mm |

Minimum feeding length | 350 mm |

Maximum feeding length | 6500 mm |

Minimum nominal cross section | 150*20mm |

Maximum nominal cross section | 120*50mm |

The maximum cutting tolerance can reach 1.2 meters fixed length | 0.8-1.5 mm |

Maximum feed speed | 150 m/min |

Cutting cycle time (braking, cutting, accelerating) | ≤0.2 seconds |

Electrical connection load | 14 kW |

Gas consumption | 1000L/min |

Operational Pressure | 6-8 bar |

Extraction speed | 30 m/s |

Extraction volume | 2500 cubic meters/hour |

Finger jointing machine

Cross-cut sawing machine

We can customize suitable products according to your needs.

Reference Parameters

Reference Parameters

Saw motor performance | 7.5 kW |

Maximum cutting height | 110 mm |

Maximum cutting width | 300 mm |

Electrical connection load | About 18KW |

Gas consumption | About 100N/min |

Operational Pressure | At least 6 bar |

Extraction speed | About 30 m/s |

Extraction volume | About 1300m3/h |

Dust removal diameter | 125 mm |

Horizontal sawing machine

We can customize suitable products according to your needs.

Reference Parameters

Reference Parameters

Maximum processing size | 400*300mm | Saw wheel motor | 18.5 kW |

Distance from saw blade to work table | 3~300mm | Hydraulic | 55 kg/m3 |

Conveyor belt width | 385 mm | Dust exhaust diameter | 102mm*2 |

Saw wheel diameter | 800 mm | Saw blade size (length*width*height) | 5182*50*0.9mm (1.3 inches) |

Feed rate | 0~18m/min | Saw cut | 1.2~2.2mm |

Saw wheel lifting motor | 0.18 kW | Overall size (length*width*height) | 3000*1950*2200mm |

net weight | 1830 kg |

Double end milling cutter

1. The crawler adopts rolling bearings and the guide rail is inlaid with super-hard materials to ensure the processing accuracy and extend the service life of the machine. 2. The double-end milling adopts imported PLC and inverter control to ensure that the machine is very stable during operation. 3. Powerful feeding reducer, frequency conversion speed regulation. 4. The crawler structure is equipped with a cleaning brush wheel, which can automatically clean the dust in the guide rail. 5. The compact saw shaft structure can make the tool as close to the pressure belt as possible to ensure the stability of processing. 6. The structure of the ball screw makes the machine adjustment more accurate.

Specifications | VH-MX2626D | Saw shaft diameter | 25.4 mm |

Feeding speed | 6-30 m/min | Width adjustment motor power | 0.75 kW |

Minimum working width | 300 mm | Total Power | 29.25 kW |

Maximum working width | 2600 mm | Spindle speed | 6000 rpm |

Minimum processing thickness | 10 mm | Powered takeoff and landing | 0.25 kW |

Maximum processing thickness | 60 mm | air pressure | 0.6 MPa |

Feed motor power | 3 kW | Length from upper pressure beam feeding end to stopper | 1500 mm |

Scoring saw motor power | 3kW×2 | Saw axis rotation | 2800 rpm |

Main saw motor power | 4kW×2 | Maximum micro saw blade diameter | 230 mm |

Spindle motor power | 5.5 kW x 2 | Maximum scoring saw blade diameter | 230 mm |

Maximum tool diameter | 200 mm | Spindle size | 40 mm |

Air outlet size | 120 mm | Vertical spindle rotation | 9000 rpm |

weight | 5000 kg | aspect | 3450x2600x1670 mm |

contact us

1. Who are we? We are headquartered in Fujian, China, and we start selling to domestic market (60.00%), Southeast Asia (5.00%), Central America (5.00%), North America (5.00%), South Asia (4.00%), Northern Europe (4.00%), Africa (3.00%), Middle East (3.00%), Oceania (2.00%), Southern Europe (2.00%), East Asia (2.00%), Eastern Europe (2.00%), Western Europe (2.00%), South America (1.00%) since 2016. There are 11-50 people in total in our office. 2. How do we ensure quality? There are always pre-production samples before mass production; There is always a final inspection before shipment; 3. What can you buy from us? Woodworking machinery, Circular saw blades, Bi-metal band saw blades, Woodworking tools, Metalworking machinery 4. Why should you buy from us instead of other suppliers? Xiamen Chuangtai Technology Co., Ltd. is a professional enterprise engaged in R&D, manufacturing and sales. Since 2000, we specialize in woodworking machinery, pipe cutting and bending machines, woodworking tools, band saw blades. 5. What services can we provide? Accepted delivery terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES; Accepted payment currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF; Accepted payment types: T/T, L/C, D/PD/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow; Languages used: English, Chinese, Russian

VIEW MORE

You may like

-

Disposable wooden tableware machine wooden spoon and fork making machine spoon forming machine

-

Fully automatic hydraulic European standard wooden pallet making machine | Wood sawdust for wooden pallet hot press forming machine

-

Wooden Spoon Heat Press Fully Automatic Wooden Spoon Production Machine Fully Automatic Wooden Spoon Heat Press

-

Wooden Spoon Product Machine Ice Cream Stick Coffee Stirrer Wooden Tableware Making Machine Wooden Spoon Forming Machine

-

ZICAR woodworking CNC machines for the manufacture of furniture doors and cabinets

-

Wooden Ice Cream Stick Machine Tableware Making Machine Wooden Spoon Making Machine

-

Wooden tableware manufacturing machine spoon fork knife processing equipment production line wooden fully automatic disposable customization

-

Fully automatic laminate flooring production line laminate flooring production line

-

Saifan 700-1500mm Length Wooden Pallet Nailing Wooden Pallet Automatic Production Line

-

Conveyor feeder automatic edge banding machine production line

Other Products

-

$459.00 / piece

$459.00 / piece -

$179.00 / piece

$179.00 / piece -

$16.00 / piece

$16.00 / piece -

$15.00 / piece

$15.00 / piece -

$1499.00 / piece

$1499.00 / piece -

$190.48 / piece

$190.48 / piece -

$488.00 / piece

$488.00 / piece -

$675.46 / piece

$675.46 / piece -

$450.00 / piece

$450.00 / piece -

$103.76 / set

$103.76 / set