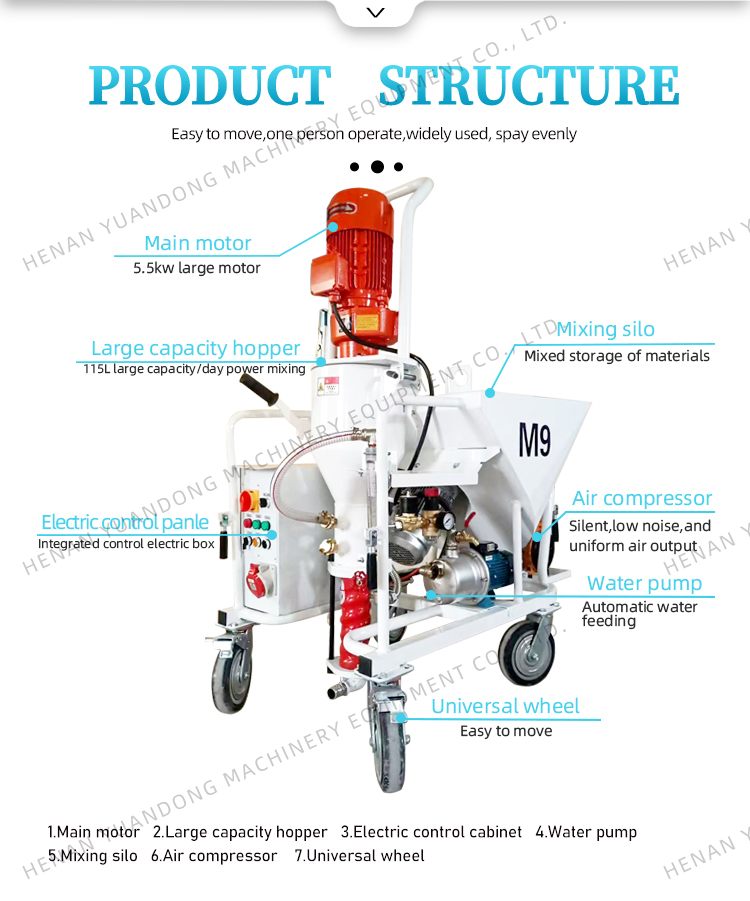

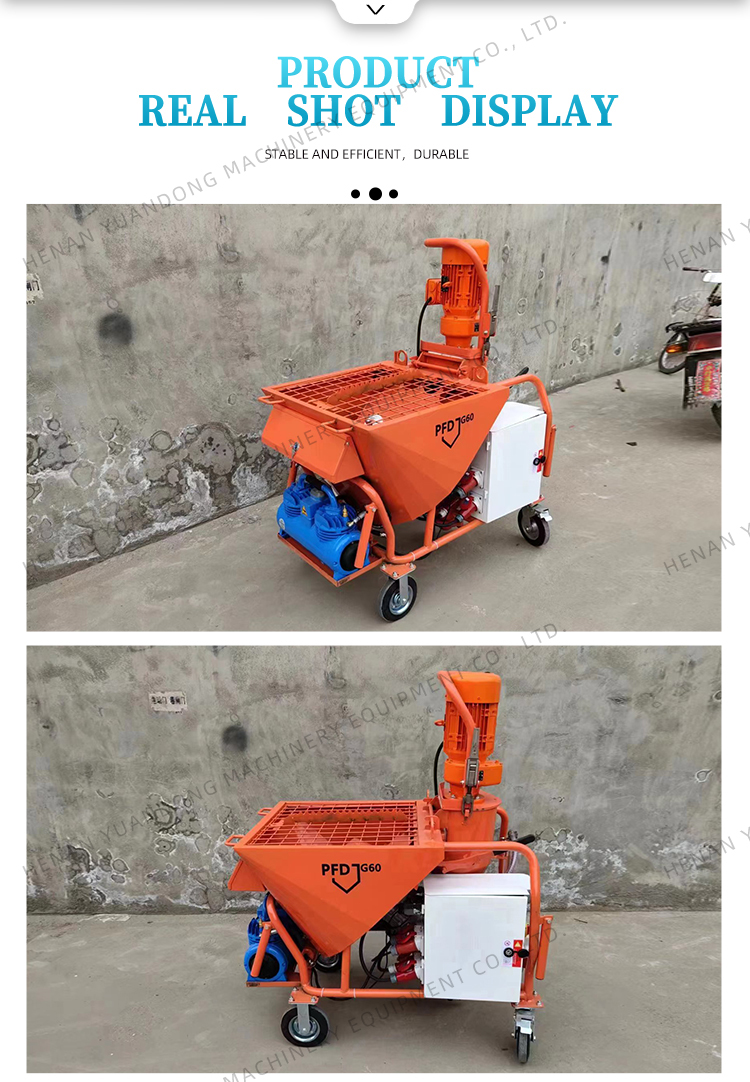

Advanced Technology Gypsum/Cement Spraying Machine 220v/380v Automatic Gypsum Plastering Station Mortar Spraying Machine

-

Supplier: Henan Yuandong Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Eddie Yang -

Price: -

Min. Order: 1 piece

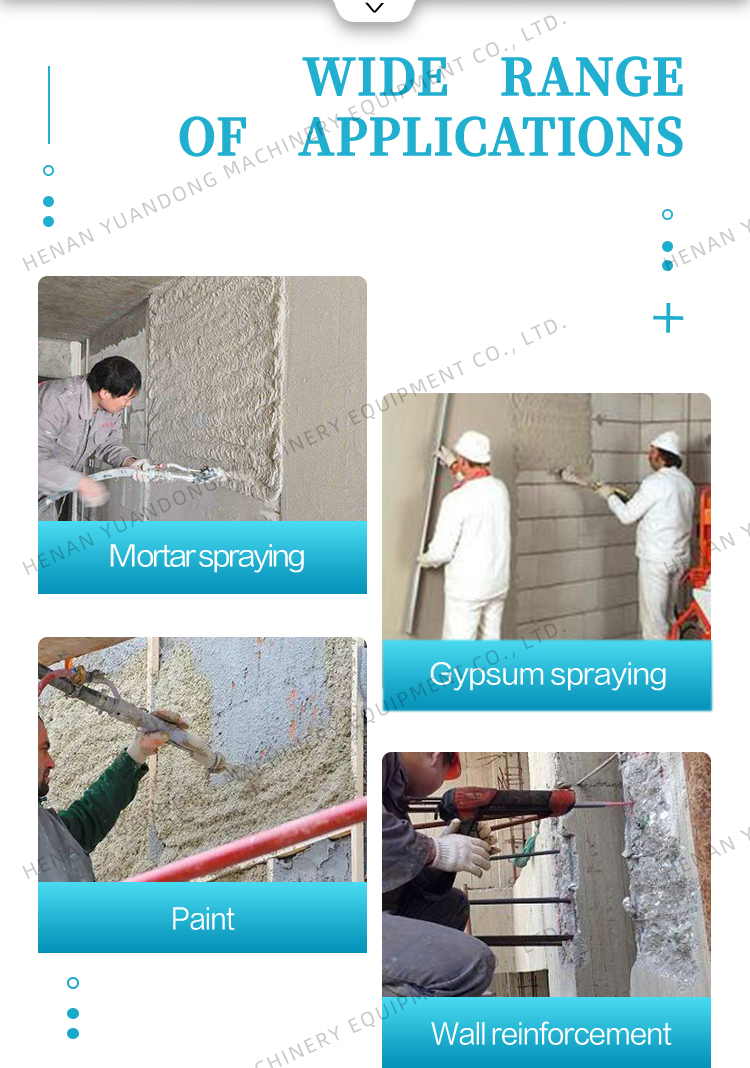

The fully automatic gypsum spraying machine integrates feeding, mixing, pumping and spraying functions into one, and is suitable for lime-based, gypsum-based, and cement-based plastering, masonry building mortar, insulation mortar, repair bonding mortar, self-leveling mortar, etc. .

|

Product name |

Gypsum spray machine |

|

Model |

UR-M9 |

|

aspect |

1230×720×1550mm |

|

gross weight |

220kg |

|

strength |

380v/50hz or customized |

|

Throughput |

30 liters/minute |

|

Standard pump pressure |

50 bar |

|

Main motor power |

5.5kW |

|

Air compressor power |

1.5kW |

|

Horizontal conveying distance |

30m |

|

Vertical conveying distance |

20m |

|

maximum particle size |

3mm |

|

Hopper capacity |

115 liters |

|

Hopper height |

90cm |

1. Reasonable design, integrated pump and compressor, easy to move.

2. Continuous feeding, no pulse phenomenon, uniform spraying and strong adhesion.

3. Basically no floor ash is produced, saving water and materials, and can reduce costs by more than 20%.

4. The nozzles are universally connected, and the inner and outer corners and the top plate can be sprayed freely, which is convenient.

5. Wide applicability, one machine can be used for multiple purposes, and can spray gypsum, putty, mortar, fire retardant coatings, refractory materials, etc., and is not affected by regional and environmental conditions and the shape of the sprayed surface.

Multifunctional spraying machine suitable for pumping all ready-mixed dry mix mortars such as self-leveling mortar, plastering mortar, lime plastering mortar, cement mortar, lime cement mortar, polymer mortar, plastering cement mortar, clay mortar, thermal insulation Mortar and other materials, grouting mortar, fireproof mortar, floor mortar, seaweed mud, insulation mortar, putty, primer, wall paint, masonry mortar, etc.

-

Cheap 220V 15M3/H wall plastering machine automatic mortar sprayer paint sprayer

-

Efficient Mortar Plastering Spraying Machine Paint Spraying Machine Concrete Plastering Machine Cement Spraying Machine

-

Concrete spraying machine New diesel cement mortar spraying machine Mortar spraying machine

-

Hot-Sale Mortar Spraying Machine for Sand Cement Plastering

-

Factory direct Wagner plastcoat PC1030 textured mortar spraying machine

-

Wholesale Mortar Spraying Machine Concrete 70L 90L 100L 120L 200L Spraying Ceiling Mortar Spraying Machine Price

-

Professional Mortar Texture Sprayer Machine Spray Painter Shotcrete Machine For Sale

-

New pu foam spray machine in China

-

Cement Mortar Sprayer High Efficiency Single Phase 220v for Small Project Construction Work

-

Automatic Mortar Sprayer Price High Quality Wall Mortar Gun Cement Electric Diesel Mini Stucco Plasterer/Sprayer

Other Products

-

-

$100.00 - $110.00 / set

$100.00 - $110.00 / set -

$373.00 - $385.00 / set

$373.00 - $385.00 / set -

$587.00 / set

$587.00 / set