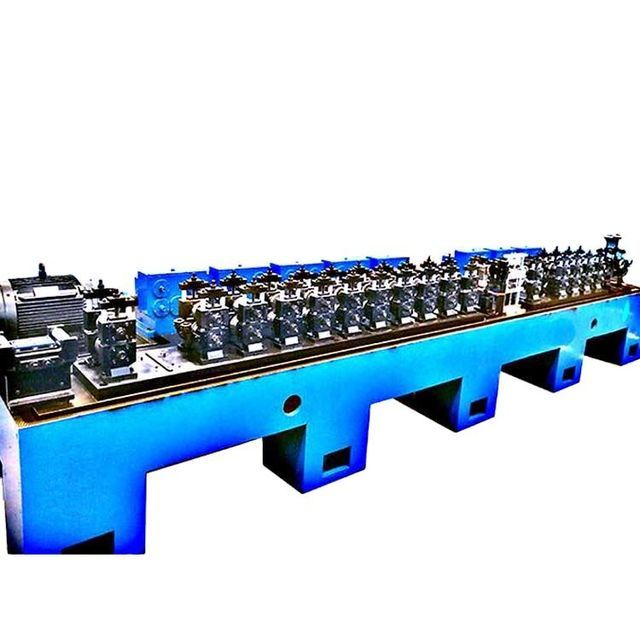

Insulated double glass spacer profiler for manufacturing and production of aluminum gasket profiler

-

Supplier: Liaoning Alger Building Material Industrial Co., Ltd. -

Region: Liaoning, China -

Contact: Mr Alger yan -

Price: -

Min. Order: 1 piece

Product details

Product Description

High frequency welding aluminum spacer equipment

It can produce aluminum gaskets 0.18mm-0.35mm. Welding speed is 140m/min, cutting length: of course, other lengths can be generated in order;

It uses advanced coil and water-free high-frequency welding technology, including all equipment, including disassembly machines,

Forming machines, scraper and vacuuming settings, straightening equipment, industrial transfer belts, automatic transfer belts

Length setting computer saw, automatic feeding table, high-frequency welding machine for welding aluminum gaskets, matching water cooling system, etc.

It uses advanced coil and water-free high-frequency welding technology, including all equipment, including disassembly machines,

Forming machines, scraper and vacuuming settings, straightening equipment, industrial transfer belts, automatic transfer belts

Length setting computer saw, automatic feeding table, high-frequency welding machine for welding aluminum gaskets, matching water cooling system, etc.

Equipment composition:

It includes disassembly machines, forming dimension machines, scrapers and vacuum settings, straightening equipment, industrial transfer

Belt transmission, automatic length setting computer saw, automatic feeding table, high frequency welding machine for welding

Aluminum gaskets, matching water cooling system, etc.

Belt transmission, automatic length setting computer saw, automatic feeding table, high frequency welding machine for welding

Aluminum gaskets, matching water cooling system, etc.

Advantages of unit equipment:

High precision; can produce aluminum gaskets from 0.18mm to 0.35mm, high thickness: our unit equipment speed is much higher than our competitors; Internal cycle: Internal cycle without water, no manual sunlight tube required, you can Packaging materials are free of charge for direct commissioning: After you debug the equipment, it can be directly placed in the raw materials and produced; guarantee quality: We guarantee to choose raw materials, processing technology, national or international high-quality spare parts; Gao Gao;

Quality products: truncated surface of aluminum gaskets, which looks easy to pack; good working conditions: less noise and no pollution; Energy saving: energy saving than similar products; Small land occupation: can save too much land Occupation; Save labor: only 2 workers are required, so it can save too much cost;

Quality products: truncated surface of aluminum gaskets, which looks easy to pack; good working conditions: less noise and no pollution; Energy saving: energy saving than similar products; Small land occupation: can save too much land Occupation; Save labor: only 2 workers are required, so it can save too much cost;

usage

VIEW MORE

You may like

-

CE/UL insulating glass making machine double-layer glass machine insulating glass production line

-

Production line of glass insulators

-

CE certification and new status insulating glass machine/double glazing machine/insulating glass production line

-

CNC Glass Cutting Machine Float Glass Cutting Machine Multifunctional Glass Cutting Machine

-

Sealant Sealer / Sealant Extruder

-

Glass Bottle Making Machine Production Line 2020 China Glass Bottle Furnace / Glass Bottle Furnace Production Line Project "This in Hand"

-

Glass Grinding Machine Glass Grinding Polishing Machine Portable Glass Edge Grinding Polishing Machine

-

SY-1000 single side horizontal glass edging machine

-

glass production line

-

beer bottle production line

Other Products

-

$42000.00 / set

$42000.00 / set -

$1589.00 - $1600.00 / set

$1589.00 - $1600.00 / set

Related Search

battery for car and truck manufacturer

hot melt machine double glass

hoes for farm and garden

mixer for still and carbonated beverages

fashion hot sale leather belt for man and woman suppliers

double sides timing belt for industrial

compressor for refrigerator and freezers

caps for bottles and jars suppliers

vacuum cleaner for wet and dry

solar power for lighting and radio