HSS HTD 5M 8M 14M Timing Belt pulley Hob Cutter

-

Supplier: Chongqing Yuqing Machine Tools Co., Ltd. -

Region: Chongqing, China -

Contact: Ms Sabrina Tang -

Price: $38.00 / >=3 pieces -

Min. Order: 3 pieces

| Packaging Detail: | Package of HTD 5M 8M timing pulley hob cutter : oiled paper+carton+wooden case or as requirement; | Model Number: | Standard size; |

| Payment Terms: | L/C,D/P,T/T,Western Union,MoneyGram,Paypal; | Material: | HSS; |

| Machine Type: | Hobbing Machine; | Supply Ability: | 5000 Piece/Pieces per Month; |

| Module: | HTD 5M 8M 14M; | Brand Name: | YQ; |

| Material: | M2/M35; | Color: | Golden/Silvery; |

| Coating: | TIN/TIALN; | Delivery Detail: | within 25 days; |

| Place of Origin: | Chongqing China; | No.of start: | Single; |

| Port: | Shenzhen; | Usage: | Gear Hob; |

HSS HTD 5M 8M 14M Timing Belt pulley Hob Cutter

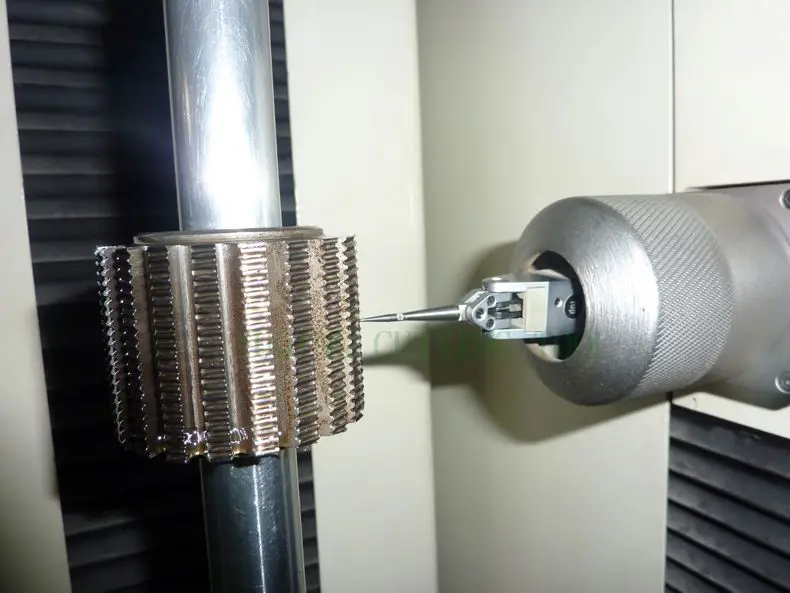

It is used to machining synchronous pulley

Specification table of timing belt pulley hob cutter :

Timing pulley profile | Belt type | Common arrange | Size |

S.T.D | MXL(2.032) | 10-23T 24-R | 32×25×13 |

XL(5.08) | 10-R | 55×50×22 | |

L(9.525) | 10-R | 55×50×22 | |

H(12.7) | 14-19T 20-R | 70×60×27 | |

XH(22.225) | 18-R | 85×85×32 | |

XXH(31.75) | 18-R | 90×90×32 | |

H.T.D | 2M |

| 50×40×22 |

3M | 9-15T 16-25T 26-80T 81-R | 50×40×22 | |

5M | 11-16T 17-31T 32-79T 80-200T | 50×50×22 | |

8M | 18-27T 28-40T 41-89T 90-200T | 70×65×27 | |

14M | 28-40T 41-89T 90-R | 75×75×27 | |

20M |

|

| |

S.T.S | 2M |

|

|

3M | 16-25T 26-80T | 50×40×22 | |

5M | 20-24T 25-40T | 55×60×27 | |

8M | 20-24T 25-31T 32-48T 49-120T | 70×65×27 | |

14M | 28-36T 37-51T 52-100T 101-200T | 75×75×27 | |

20M |

|

| |

A.T.(D.T) | A(T5) | 10-14T 15-20T 21-R | 55×45×22 |

T10 | 12-15T 16-20T 21-R | 65×60×27 | |

T20 | 15-20T 21-R | 80×80×32 | |

(D)T5 | 13-17T 18-25T 26-40T 41-R | 55×45×22 | |

T10 | 12-15T 21-R | 65×60×27 | |

T20 | 15-20T 21-R | 80×80×32 | |

G.T. | 2GT | 16-25T 26-80T |

|

3GT | 25-26T 26-50T |

| |

5GT | 17-31T 32-79T |

| |

8GT | 18-28T 29-89T |

|

Hob cutter series : gear hob , pre-shaving gear hob, pre-grind gear hob, involute spline hob, parallel side spline hob, ground sprocket hob , and timing pulley hob.

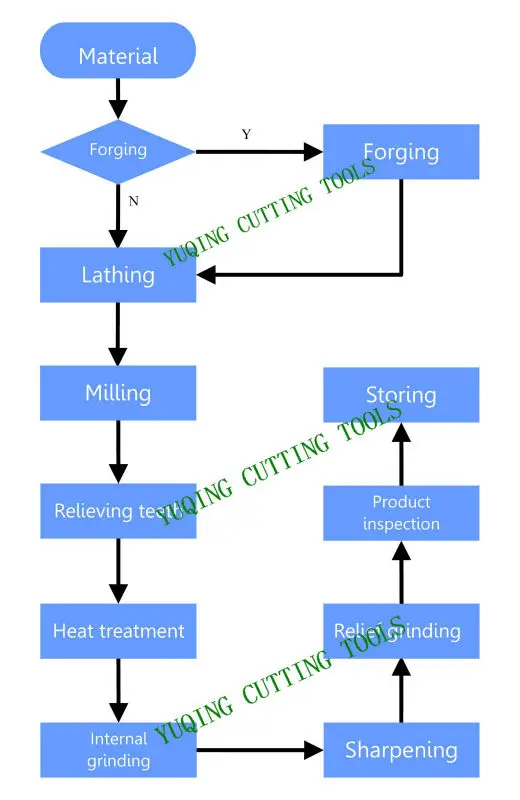

The production process of timing belt pulley hob cutter :

Production process of HTD 5M~14M timing pulley hob cutter :

Material Introdution:

A. W6Mo5Cr4V2 (GB) M2( ASTM), S6-5-2(DIN), SKH51(JIS)

chemical composition:C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

main application:It is widely used for making all kinds of cutters and durability cold-work die

B. W6Mo5Cr4V2Co5 (GB), M35( ASTM), 1.3243(DIN), SKH55(JIS)

chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

main application:It is often used for making blades with high-speed and great cutting difficulty as it’s good abrasive resistance

-

High-speed gear hobbing cutter M0.15-M1 micro gear hobbing cutter

-

Gear cutter module m16 in stock

-

Pulley Hob Flat Cutting Blade Clothing Sewing Hand Tools Cloth Wheel Knife Round Hob

-

EJ 6.5 Gear Hobbing Machine Hobs

-

Good Price Guaranteed Quality High Speed Steel Double Gear Cutting Hob Gear Hob For Gear Cutter Machining Tools

-

High quality and low price customized various specifications gear milling cutter gear cutter

-

HSS 5M/8M/14M Timing Pulley Hob Single Start

-

FEDA DC53 Thread Rolling Die High Quality Thread Rolling Die Manufacturer

-

Vanore Carbide Gear Cutting Tools for Gear Cutting

-

Coated hob M1/M1.5/M1.75/M2 small modulus gear hob

Other Products

-

$69.00 / set

$69.00 / set -

$38.00 / piece

$38.00 / piece -

$38.00 / piece

$38.00 / piece -

$12.00 / piece

$12.00 / piece -

$18.00 / piece

$18.00 / piece -

$4.50 / piece

$4.50 / piece -

$38.00 / piece

$38.00 / piece -

$68.00 / set

$68.00 / set