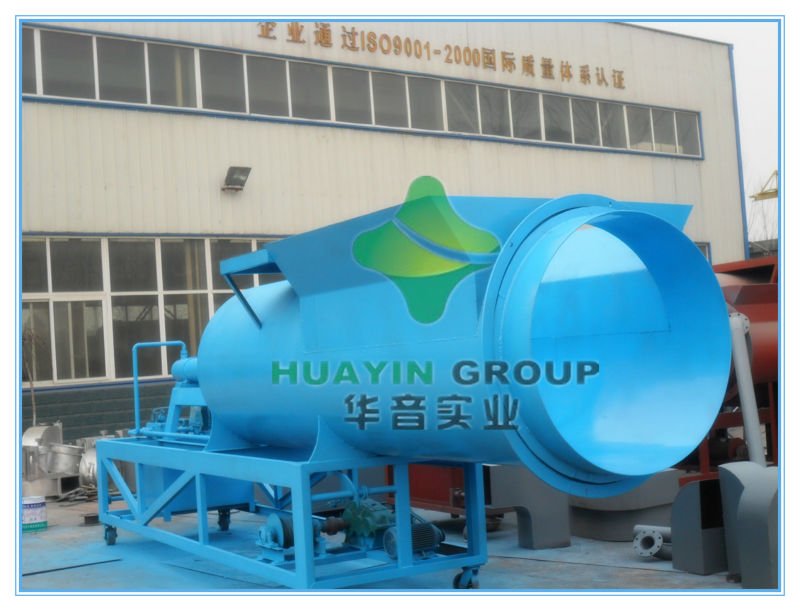

newest design waste tire to crude oil pyrolysis plant with CE and ISO

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Zora Xu -

Price: $40000.00 /set -

Min. Order: 1 set

| Thickness of Reactor: | 12/14/16/18mm; | Packaging Detail: | Container, frame container or according to customers' requirements; |

| Voltage: | 380V; | Tire Machine Type: | Tire Recycling Machine; |

| Material of Reactor: | Q245R boiler plate; | Weight: | 38 ton; |

| Diameter Size of Feeding: | 720mm/1200mm; | Supply Ability: | 30 Set/Sets per Month according to customers' requirements; |

| Port: | Qingdao or Tianjin; | Power(W): | 20kw; |

| Condition: | New; | Main Motor Power: | 3Kw; |

| Driving Method: | Gear drive; | After-sales Service Provided: | Field installation, commissioning and training; |

| Applicable Industries: | waste pyrolysis; | Warranty: | 1 Year; |

| Certification: | ce iso; | Dimension(L*W*H): | 2800mm*6600mm; |

| Brand Name: | Huayin; | Key Selling Points: | Energy saving; |

| Payment Terms: | L/C,T/T; | Size of Reactor: | D2800mm*6000mm; |

| 24-hour Capacity: | 10 ton; | Year: | 2019; |

| Type: | waste tire pyrolysis plant; | Raw Material: | Tire/ plastic; |

| Rotate Speed of Reactor: | 0.8turn/minute; | Oil yield: | 4.5 ton; |

newest design waste tire to crude oil with CE and ISO

Waste to Oil Energy

Day be day, waste tire, waste plastic, waste rubber, waste oil cause serious environmental pollution.

Most people have no idea about how to dispose of these house waste or industry waste.

Burning, landfill, actually are not the right way to solve the problem.

We have the honor to introduce you the green technology for waste recycling.

Waste tire recycling machine, waste plastic recycling machine, also named as pyrolysis equipment.

Waste engine oil recycling machine, oil residue recycling machine, also named as distillation equipment.

After being processed, all the tire or plastic will be fully recycled, most percent are turned into fuel oil, the others are carbon black and fuel gas. It does not cause secondary pollution.

Meanwhile at most area of the world, the cost of raw meterial is very very low. Because actually they are waste things. People are willing to cooperate with you as waste management. After recycling these waste things are turned into treasure.

Diagram of waste tire/plastic pyrolysis machine

Reactor

1. The gear is seperated from reactor, instead of welding on reactor. So it will not be destroyed by heating.

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

Auto-feeder

1. 50 ton hydraulic pressure help feeding more raw materials.

2. The diameter is 1.4m. It can feed all kinds of raw materials, including plastic, packages of plastic, truck tire, car tire, or tire pieces after cutting.

2. Save labor, save time.

3. After finishing production it can feed raw material instead of waiting the reactor to be cooled.

Catalyst chamber

1. Improve the oil yield and oil quality.

2. Impurity of oil gas will be collected here.

3. Reduce the speed of oil gas so that it will be better cooled.

Oil-water separator

1. Water from raw material will be separated here.

2. Water sealing design prevent tempering. Ensure saftety.

3. Heavy oil will be collected here.

Condenser

1. The oil gas is cooled separately by 57 pipes inside the condenser. Improve the oil yield by better cooling effect.

2. Series connection for condenser makes the cooling process longer.

3. Light oil will be collected here.

Vacuum device

1. Keep reactor running under normal pressure.

2. Ensure safety.

Anti-back fire device

1. Little residual gas can not be cooled. It will recycle these gas to furnace burning to heat the reactor.

2. Water sealing disign will prevent tempering. Ensure safety.

Dust removal device

1. Dispose of flue gas caused by heating reactor using coal, wood, oil or natual gas.

2. Environment protection.

Certificates

We have ISO9001:2008, ISO14001:2004, CE, SGS, BV and patents for every part of our equipments.

1. We will send engineer to guide installation and training workers operate the machine.

2. One year warranty for each set machine.

3. Help customers do feasibility report.

4. Provide assistance on project .

5.24 hours online .Your inquiry will be quick reply by email .

6. Sample testing support.

7.View our Factory.

8. Professionally and patiently introduction,details pictures and working video to show machine

Huayin Energy focuses on equipment manufacturing, project development and turnkey facility operations.

Thermal Decomposition Plants manufactured by HUAYIN are efficient at:

1. Solid Waste Management: processing of rubber and used tires, OTR tires, plastic waste and other hydrocarbons;

2. Liquid Waste Management: processing of waste muds, drilling solutions, oil sludge, waste engine oil, motor oil and lubricating oil;

3. Energy Recovery: MSW recycling to energy solution.

Machine delivery from our factory Our 10 tons pyrolysis reactor is about 9200m *33400mm*31700mm. It is doable to take 40’FR. It is over width and over height. And Our integrity cooling device is designed to meet 40‘HQ size and it is easy to ship and move the site place. Delivery time will be 25 working days. |

Q1 : IS that possible to be your agent or distributer ?

Yes , of course , we are glad to work with you to develop the market.

Feel free to contact with us to get more information .

We are the OEM manufacturer for pyrolysis and distillation machine , we are developing partners to occupy our market.

Q2. How to ensure the delivery time ?

We have modern high automation production lines , usually it is just take 5 days to finish producing one set machine.

Moreover , we have prepared machines in our workshop , urgent orders can be negotiated .

Q3. What is your payment terms ?

The Payment terms can be EXW , FOB , CIF , CFR , L/C terms etc.

Other terms can be negotiated.

Q4. Do you provide oil samples ? What is the delivery time ?

Yes , OIl samples can be provided . The delivery time shall be 5 working days.

Q5. Do you produce portable size machine ?

Yes , the smallest capacity is 10kg portable size , we can produce it according to customer requirement.

newest design waste tire to crude oil with CE and ISO

newest design waste tire to crude oil with CE and ISO

Welcome to contact for further discussion.

Welcome to visit us.

-

1-6 axis/shaft type rubber gasket cutting machine for gaskets or rubber rings

-

Rubber pressure bladder for Almex Eupno Beltwin vulcanizing presses

-

Metal Plastic Crusher Biaxial Pet Bottle Grinding Multifunctional Tire Shredder Tire Crusher

-

Factory Direct Sales Truck Radial Tire Retreading Machine/Tyre Retreading Equipment

-

Scrap Tire Sidewall Polishing Machine Circular Cutting Blade

-

Waste Tire Recycling Machine Tire Pulverizer Machine for Rubber Pulverizer

-

Scrap Big Truck Tire Sidewall Cutting Machine Mechanical Recycling Tire Cutting Machine Recycling Machine

-

open mixing mill

-

UT-A2100 Portable Heat Press Machine PVC Conveyor Belt Vulcanizing Machine Air-cooled Crimping Machine

-

Rubber floor tile vulcanizing machine/rubber floor mat making machine

Other Products

-

$30000.00 / set

$30000.00 / set -

$35000.00 / set

$35000.00 / set -

$38000.00 / set

$38000.00 / set -

$48000.00 / set

$48000.00 / set -

$40000.00 / set

$40000.00 / set -

$55000.00 / set

$55000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$16000.00 / set

$16000.00 / set