Metal or steel door frame or window frame making machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $15000.00 /set -

Min. Order: 1 set

| Weight: | about 5.5 t; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Power(W): | about 5.5kw; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Supply Ability: | 30 Set/Sets per Year; |

| Power of main machine: | 5.5 kw; | roller material: | GCr12MoV; |

| Production Capacity: | 15 m per min; | Packaging Detail: | 1.One 20ft or 40ft container for loading one set machine with manual decoiler. 2.The whole wiped anti rust oil ,PLC controller covered by foam film. 3.Spare parts and some small parts packed in plastic tooling box. 4.All components of steel ?door jamb cold roll formings fixed by steel wire.; |

| shaft material: | 45# steel with tempering; | Blade mould material: | GCr12MoV; |

| Dimension(L*W*H): | about 6500x1200x1500mm; | Port: | Xingang port, tianjin, china; |

| Applicable Material: | Stainless Steel,Carbon Steel,Aluminum; | Forming steps: | 16stations; |

| Work speed: | 0-15m/min; | Thickness: | 0.65-1mm; |

| Transport: | By gear; | Raw material: | Galvanized; |

| Certification: | CE ISO; | Voltage: | customized; |

| Shaft diameter: | 50mm; | Brand Name: | Zhongtuo; |

| Warranty: | 1 year; |

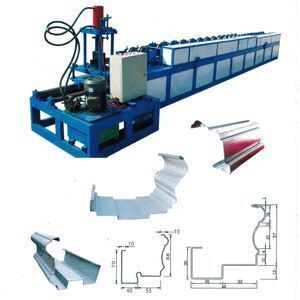

Metal or steel door frame or window frame making machine

Steel door frame making machine is designed to roll form the galvanized steel to the door frame or window frame shape. Normally the thickness of the door frame or window frame is from 0.65mm to 1.0mm. Our door frame machine is widely used in the steel door or steel window manufacturing. Steel door frame machine consists of uncoile, leveler, mail roll forming machine, cutting part, runout table, PLC control box and hydraulic station. The whole machine are controlled by the industrial PLC, which can gurantee the machine work automatically and precison of the final products.

1. Door frame machine Processing flow:

Manual de coiler→Guide roller→Feeding material →Leveling→punching→roll forming→strengthening→Hydraulic cutting→product receiving table

2. Door frame machine Profile drawing:

Our steel door frame making machine is customized, we can design the machine as customers' personal requirements. Customer can send us samples or send us the profile drawing of the door frame or window. Here below I attached some door frame profile drawings for you reference, if you have this machine demand, please let me know your personal requirements and then I can prepare a machine proposal for you.

Other related products profile drawing for you reference:

3. Door frame machine Technical parameters:

Configurations | manual decoiler, feeding, Punching, main machine of roll forming, cutting part, hydraulic station, Delta PLC control system, run out table | |||||

Material | Raw material | Galvanized | ||||

Thickness | 0.65-1mm | |||||

Material hardness: | 550 MPA---350 MPA | |||||

Manual decoiler | Inner Diameter: 450-550mm | Expand by manual | ||||

Max Coil width:300mm | ||||||

Capacity: 3T | ||||||

Main Forming machine | Forming steps | 16stations | ||||

Shaft diameter | 50mm | |||||

Design type | middle plate welded,Memorial arch frame type | |||||

Frame thickness | 25mm | |||||

roller material | GCr12MoV | |||||

shaft material | 45# steel with tempering | |||||

Work speed | 0-15m/min | |||||

Transport | By gear | |||||

Power of main machine | 5.5 kw | |||||

Hydraulic cutting and punching system | Power supply | Hydraulic station | ||||

punching mould material | GCr12MoV | |||||

Blade mould material | GCr12MoV | |||||

no distorting or wasting. High level safety factor. | ||||||

Hydraulic system | Hydraulic oil | 46# | ||||

Power | 3kw | |||||

Cutting length | As required | |||||

No distorting or wasting. High level safety factor. | ||||||

Control Device | control | By PLC | ||||

PLC language | English and Chinese (or as required) | |||||

Screen | Touch screen | |||||

Function | Automatic length ,punching and quantity measurement | |||||

Other Spare part | Weight | About 3 ton | ||||

Dimension | 4300*800*1400mm L*W*H | |||||

Main body color | As you need | |||||

Voltage | 380v/50hz/3ph(or as required) | |||||

Spare cutting blade | One piece | |||||

Fuse | 2 pieces | |||||

Relay | 2 pieces | |||||

Travel switch | 2 pieces | |||||

Solenoid valve | 1 pieces | |||||

Terms of payment | 1. 30%T/T ,Balance to be paid before shipping after inspection. 2.Deliver time: 35 working days. | |||||

Warranty and Training | 1. Warranty: Support the technology all the life. And the machine broken because of quality, we can change the broken part for free within one year. 2. Training: If you come to our factory,we can teach you for free. If you need technician go foreign, the buyer need pay the cost for visa, hotel, ticket, food and others, and buyer need pay the technician USD50/day for salary. There need one technician. Training time will be one week. | |||||

If you want check the details of our steel door frame making machine, here below is our machine YOUTUBE links, you can check them:

Cangzhou zhongtuo roll forming machinery co., ltd as a manufacturer since 1996, we are specialized in manufacturing purlin machine, roller shutter door machine, t grid machine, stone coated roof sheet machine, angle bead machine, pipe welding machine, cable tray machine, steel liner machine, roof tile machine, expressway guardrail machine, drywall profile machine, solar panel pillar machine, horizontal corrugated sheet forming machine, cut to length machine, shelf upright pillar machine, shelf panel machine,metal angle machine, floor decking machine, downpipe forming machine, door slide-way making machine, door frame making machine, wall panel making machine, interlock pipe machine, gutter machine, ridge cap machine, furring channel machine, embossing machine, hydraulic carving machine, hydraulic bending machine, simple slitting machine and so on. We can provide you one station, non-stop service. Our machines have been exported to 90 countries, such as Canada, South Korea, Russia, Holland, Sri Lanka, Malaysia, India, Brazil as so on. Our company insists on the service aim: Quality First, Credit First. We believe that we can make the future cooperation and achieve win-win.

Why choose to cooperate with us ?

1. We are professional manufacturer, we can produce best quality machine for you.

2. We have strong design ability, we can design machine as your requirements.

3. We have much experience for installation and training experience overseas.

4. We have successfully exported our machines to more than 90 countries.

5. We provide one year machine warrant and whole life technical support.

1. One year warranty, whole life technical support.

2. Installation & adjustment: We can take video for the customer and customer can also come to our factory, we can train customer how to install and adjust the machine.

3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD 80/person/day salary.

1. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you. b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

3. What can you do if the machine broken?

Our machine's warranty period is 12months, if the broken parts can't repair, we can send the new parts replace the broken parts freell, but you need pay the express cost yourself. if after warranty period, we can through negotiation to solve the problems,a nd we supply the technical support for the whole life of the equipment.

4. Can you be responsible for transport?

Yes, please tell me the destination port. We can help you to do the shipping if you need. we have rich experience in transport. We can give you the cheaper freight and send the machien to your country port.

5. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

6. How long the machine could be made?

Normally speaking, all the machines could be made without 45 working days. But if you need machines in a hurry, we can make it for you less than a month.

Click the blow machine photo to know more of our other machines ??

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

-

Aluminum profile cutting saw machine with digital instrument

-

Aluminum door and window back-to-back assembly table

-

PVC window double-sided seamless welding machine

-

90 or 45 degree aluminum angle cutting machine door and window aluminum profile cutting machine

-

Made in China High quality single head Upvc profile 45 degree angle miter saw

-

Popular machines for drilling aluminum door and window profiles

-

Aluminum Door and Window Frame Manufacturing Equipment Aluminum End Mill Machine Motor Offers Aluminum Cutting Machine

-

Made in China manufacturing door and window aluminum pneumatic punching machine

-

2021 Hot Sale Roller Door Roller Machine

-

Electric Portable Corner Cleaning Handle Tool for Small Workshop Upvc Door and Window Manufacturing

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set