Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $23000.00 / 1 - 1 sets

$15000.00 / >=2 sets -

Min. Order: 1 set

| color: | customer request | Control System: | PLC (imported brand) |

| Voltage: | 380V/220V,380V or as your request | Packaging Details: | 1. A 40ft container for loading a machine with a manual uncoiler; 2. The whole PLC controller wiped with anti-rust oil, foam film covered; 3. Spare parts and some small parts are packed in a plastic tool box; |

| weight: | 5 tons, 5 tons | product name: | embossing machine |

| Local service location: | India | port: | Tianjin Xingang |

| Production capacity: | 0-8m/min | place of origin; place of origin: | Hebei china |

| Video external inspection: | if | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | Certification: | EU standard |

| Main selling point: | long lasting | Health status: | new |

| Auto grade: | automatic | experience: | 15 years |

| Marketing Type: | New Products 2020 | brand: | Zhongtuo |

| Packaging Preview: | Mechanical test report: | if | |

| product: | floor panel | Warranty: | 2 years |

| application: | plate making | Dimensions (L*W*H): | 4m*2m*1.5m |

| strength: | 10KW | Showroom location: | India |

| Advantage: | longer working hours | Core components: | PLC, Bearings, Gearboxes, Motors, Pressure Vessels, Gears, Pumps |

| Core Components Warranty: | 1 year | Supply capacity: | 30 sets per month |

| Material: | Carbon steel | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| After-sales service provided: | Online support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support | thickness: | 1-2mm |

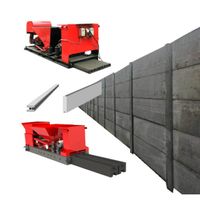

Building materials embossing metal plate plate mechanical embossing machine

The embossing machine is used to press out the part by upper and lower rollers.

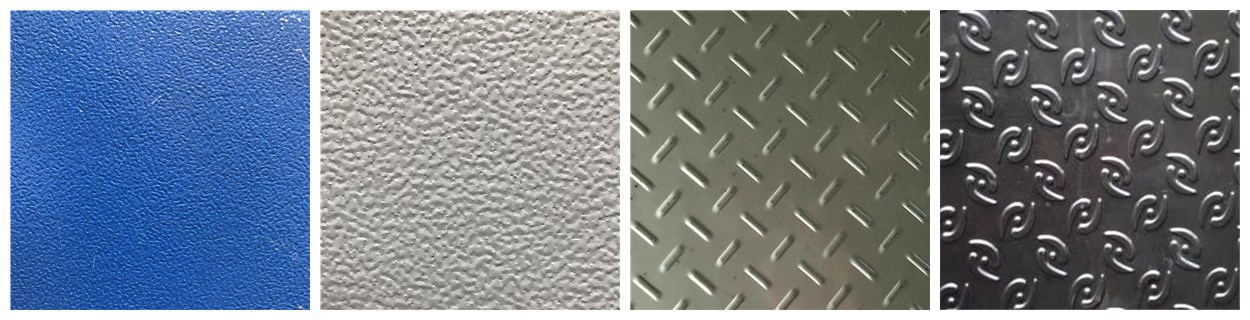

We will design the machine according to your coil or sheet width, raw material, thickness

and other requirements.

The embossing depth can also be designed if you need this for this.

About parten, you can send me your parten, or we can recommend some common types to you.

Embossing machine workflow:

Uncoiling---leveling device---embossing rolling---product collecting table

Why are our embossing machines different from other competitors?

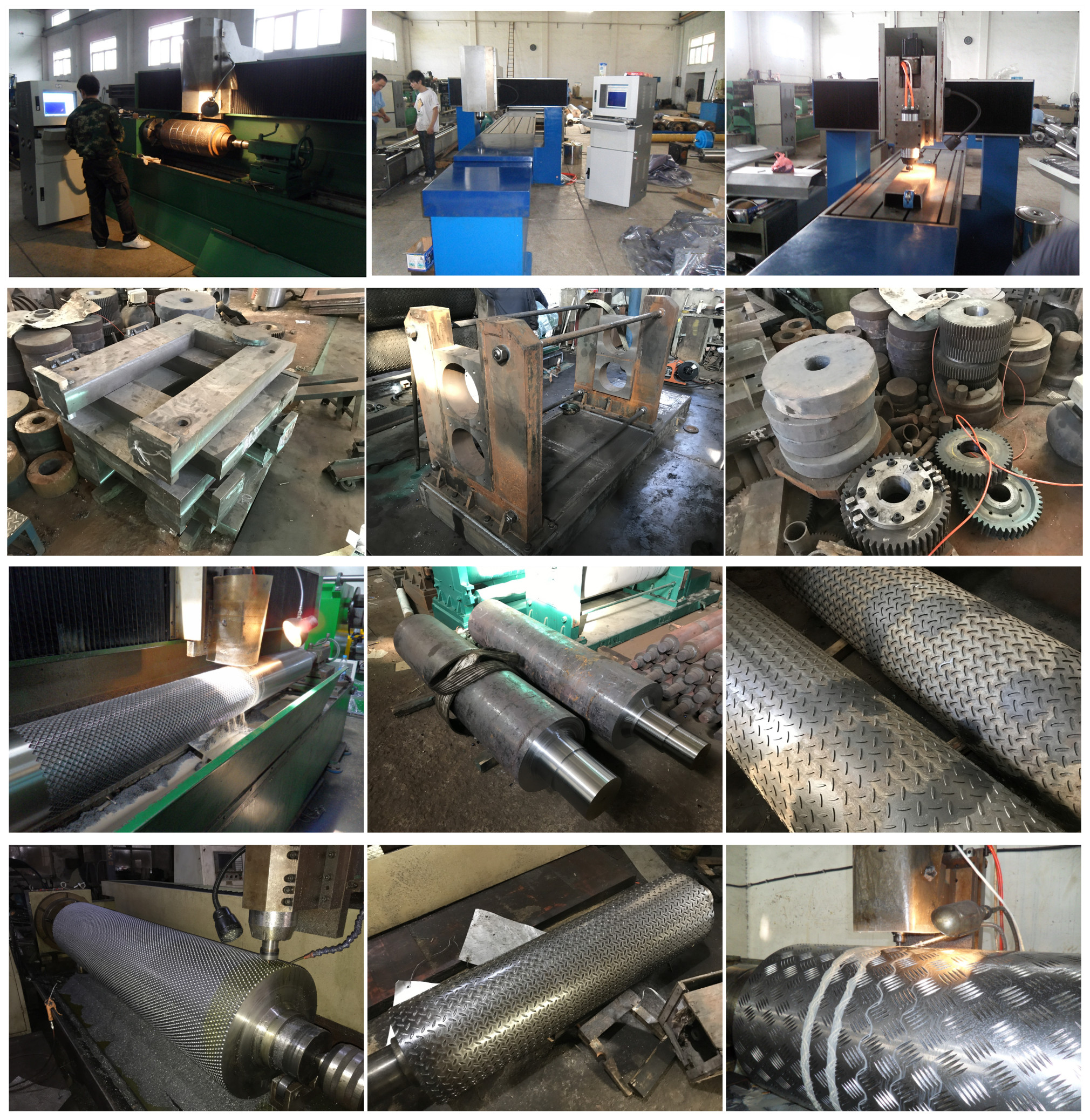

For the embossing machine, the most important thing is the embossing roller.

The higher the quality of the embossing roll, the better the embossing effect.

Therefore, to judge the quality of an embossing roller, it is necessary to detect its hardness.

The higher the hardness, the higher its quality.

Here are some photos of roller testing to demonstrate roller hardness.

Here are some photos of the embossing machine process,

From these pictures, you can see our manufacturing technology.

Some other machines used to produce metal building materials, if you need, please click the following links:

High precision metal sheet coil cutting machine slitting line

Factory offers simple-to-operate cutting-to-length and slitting machines

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

precast compound concrete hollow core wall panel making machine

-

Drywall gypsum panel/board production line

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set