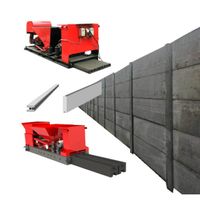

precast compound concrete hollow core wall panel making machine

-

Supplier: Guangxi Hongfa Heavy Machinery Co., Ltd. -

Region: Guangxi, China -

Contact: Mr David Yang -

Price: $10000.00 /set -

Min. Order: 1 set

| Brand Name: | HONGFA; | Single gross weight: | 1.000 KG; |

| Packaging Detail: | hollow panel making machine Seaworthy packing; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Gear,Pump; |

| Weight: | 5 kg; | Single package size: | 10X10X10 cm; |

| Marketing Type: | New Product 2020; | Application: | hollow & solid wall panels,Building Materials Machinery; |

| Power: | 4kw; | Video outgoing-inspection: | Provided; |

| Voltage: | 380/440V your requirement; | Warranty: | three years after installation,3 years; |

| Condition: | New; | installation: | engineer to install; |

| Dimension(L*W*H): | 3380*3200*2680mm; | Key Selling Points: | Automatic; |

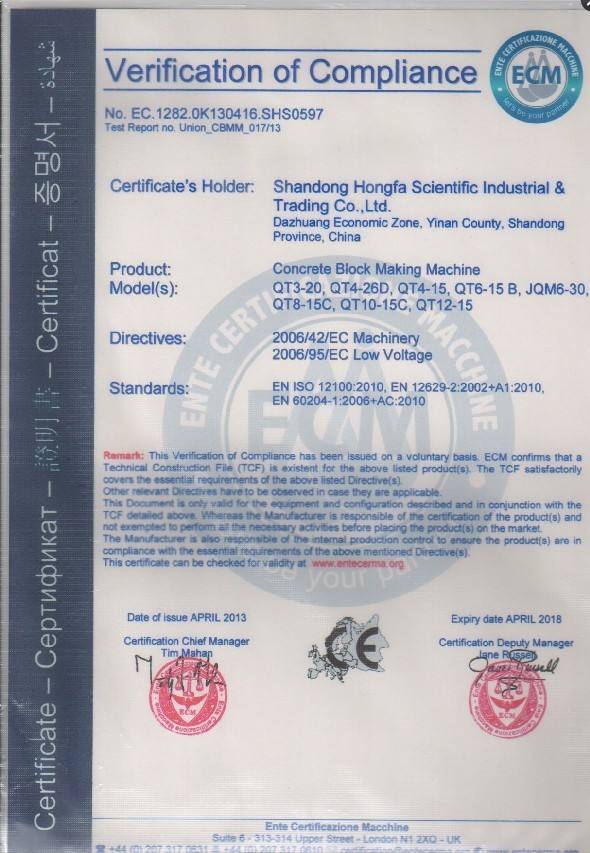

| Showroom Location: | Egypt,United States,Philippines,Pakistan,Thailand,Chile,Romania,Kyrgyzstan,Malaysia; | Certification: | CE,ISO; |

| Machinery Test Report: | Provided; | Place of Origin: | Guangxi, China; |

| Warranty of core components: | 1 Year; | Selling Units: | Single item; |

| maintain: | regular mantain; | Advantages: | fixing the mould and demoulding faster; |

| Production Capacity: | 100,000-300,000㎡/year,300,000㎡/year; | Automatic Grade: | fully auto,Automatic; |

| Features: | easy to change and fix the mould,Automatic; | Applicable Industries: | Manufacturing Plant,Construction works ; |

precast compound concrete hollow core wall panel making machine

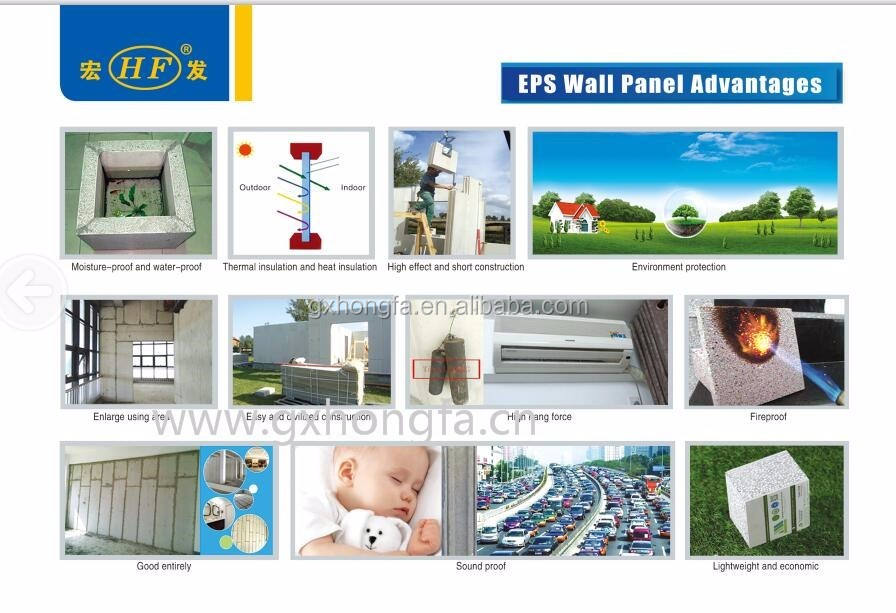

1).The concrete panel machine adopts PLC and touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

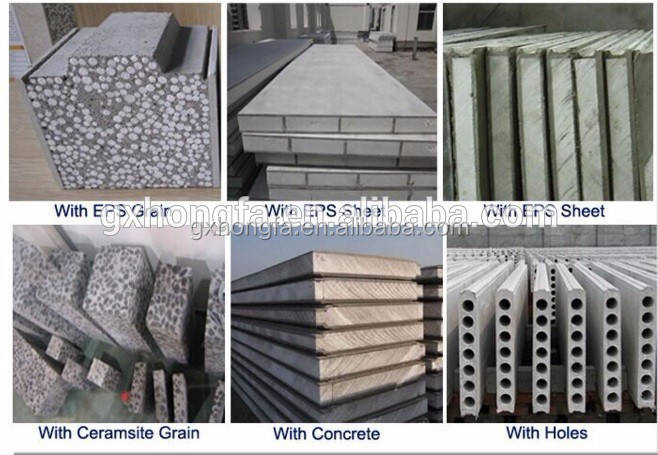

2).concrete panel machine can adjust the panel size and thickness. The thickness will be from 60 to 180mm

3).The closed constant pressure foaming barrel features of high heating efficiency and saves steam.

4).High precise guiding pressure reducing valve controls the temperature and steam pressure of the closed barrel, ensuring the outcome pressure of the valve constant and the inner temperature controlled within±1%,

which keeps the foamed material equal and prevents the bead agglomerate because of the bad temperature control.

5).With photoelectric or vibration sensor to control material level, ensuring density tolerance within ±3%.

6).The machine is equipped with fluidized bed dryer, including drying, automatic sieving, depluming and material conveying to silos.

7).World famous brands components , with reliable performance, stable quality,long service life .

8).The machine can realize the primary and second expansion

Three types of forming machines

Vertical Automatic Forming Machine

Vertical Automatic Forming Machine:

The automatic vertical type concrete panel machine

(HONGFA Exclusive Product) absorbs the advantages of vertical type and horizontal type machines.

1.It doesn't need the concrete slurry pumping machine, the concrete slurry are poured directly from the mixer, which is much faster than the pumping machine.

2. Higher capacity and efficiency than the horizontal type,almost three times higher than horizontal forming machine.

Horizontal Forming Machine

Horizontal Forming Machine:

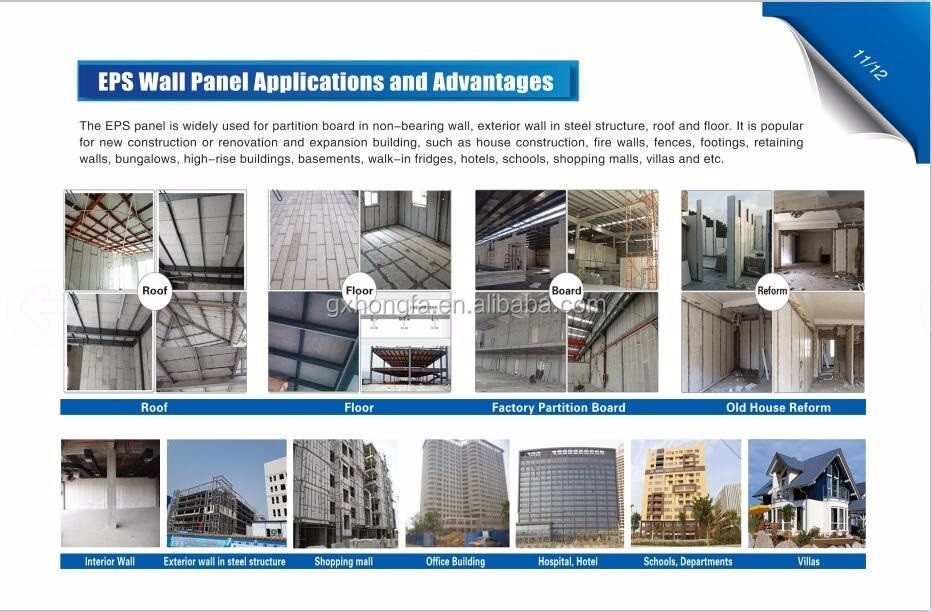

● The horizontal lightweight EPS wallboard making machine greatly reduces the labor intensity of production workers, and completely removes the disadvantages of the past vertical molds and other molds casting.

● Horizontal molding wall panel production line to solve problems like aluminum alloy plate loading of other models, not accurate size slurry per-fusion pouring, core material not full, need to manually using the steel core and vibration compaction, demoulding time problem.

Vertical Manual Forming Machine

Vertical Manual Forming Machine:

1. Simple and reliable operation, mature and stable equipment and technology.

2. For the aluminum mold of lightweight EPS sandwich concrete wall board making machine, we adopt 40mm in height and 4mm in thickness.

3. Reduce labor intensity and labor costs with special design.

Mixing Machine

Hongfa integrates with the domestic and foreign markets, takes reference from the Italian technology, independently researched and developed the foaming function forced type mixer, which stirs evenly, fully wrapped EPS particles, discharging prompt and fast.

Mobile De-Moulding Turnover Platform

This mobile de-moulding turnover platform adopts hydraulic de-moulding, which leads to fast and convenient de-moulding, and decrease the broken rate. It is convenient for finish products pallet stacking.

Mobile Injection Machine

Patent protected product, independent research and development, simple operation and easy maintenance, low cost, grouting fast, with high efficiency. High pressure infusion molding, and full filling core materials leave no dead angle, increasing yield productivity.

We are a construction and building material equipment manufacturer with more than 27 years experience and being the biggest manufacturer at present. All the products are conformity with the standard of the state and gets the ISO9001 certificate and also honored as " One of The Top Ten Famous Brands of Brick and Tile Field in China"and other honors.

Our service:

Pre-Sale Service

Analyze the customer's need and market prospect;

Provide perfect solution to set up a factory.

In-Sale Service:

Provide service of installation:

Provide training for operator and maintenance person.

After-sale Service:

Provide free consultation;

Supply parts service.

We are an ISO9001 and CE certified company,

Our quality and on time delivery is your guarantee to a successful project.

precast compound concrete hollow core wall panel making machine

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

Drywall gypsum panel/board production line

Other Products

-

$15000.00 / piece

$15000.00 / piece -

Pig farm, sheep farm automatic prefabricated manure leakage board production line manufacturer price$25000.00 / set

Pig farm, sheep farm automatic prefabricated manure leakage board production line manufacturer price$25000.00 / set