Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

Supplier: Shandong Tianyi Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr. Kevin Liu -

Price: $36000.00 /set -

Min. Order: 1 set

| Machine Features: | Easy to operate, heat preservation, fire prevention | raw material: | Cement, fly ash, water, foaming agent and other additives |

| strength: | 70kw | Voltage: | 380V |

| aftersale service provided: | Engineers available to service machinery overseas | Video shipment inspection: | if |

| weight: | 17 kg | Package preview: | |

| Automatic level: | automatic | port: | Qingdao |

| Dimensions (L*W*H): | 50*15*6.5m | Packaging Details: | 1) 40' HQ container 2) According to your demand |

| Marketing Type: | normal product | Warranty: | 1 year |

| Certification: | ISO9001 | Main selling points: | energy saving |

| Mechanical test report: | if | Production capacity: | 200-700 cubic meters / day |

| Core components: | motors, pressure vessels | application: | External wall insulation project, making cement foam insulation board |

| Applicable industries: | Building material stores, manufacturing plants, construction projects | brand: | day one |

| payment terms: | L/C, Western Union, T/T | feature: | High output, simple operation |

| Health status: | new | Local service location: | not any |

| Automatic degree: | fully automatic | Core component warranty: | 1 year |

| Origin: | Shandong China | Supply capacity: | 3000 sets per year |

| Fire-proof level: | A1 | Showroom location: | not any |

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

describe:

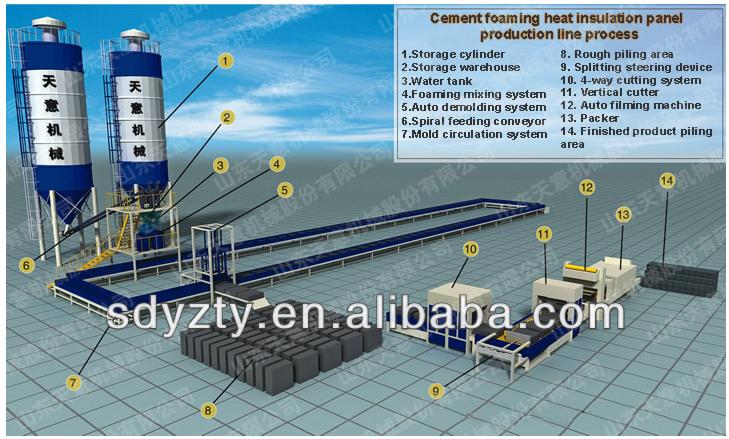

The cement foam insulation board production line is the latest complete set of equipment developed by our company according to market demand. The production line consists of mixing system, circulating grouting system, demoulding system, cutting system, packaging system, storage system and waste crushing and recycling system. The whole set of production line adopts automatic control production process, the output per shift is 150-200 cubic meters, and the required workers are 6-8, which greatly reduces the production cost.

Equipment technical parameters

| capacity | 200-500 cubic meters/day | |

| Total power(kw) | 70 | |

| need labor | 9-12 workers | |

| main process | Mixing system: automatic mixing and metering | |

| Circulation system: hydraulic propulsion circulation | ||

| Stripping system: fixed hydraulic release system | ||

| Cut-to-pack system: Simplified operation, no need to handle insulating boards | ||

raw material

Cement, fly ash, water, additives, foaming agent, etc.

manufactures

Features of cement foam insulation board

Porous, high performance lightweight inorganic sheet. cement foam insulation

Insulation boards can be widely used in building exterior wall insulation systems.

1. Green and environmental protection

No irritating and toxic gas release;

No mineral wool floaters;

No poisonous gas, no waste gas emission and less carbon emission during installation;

2. Fire prevention and high temperature resistance

High temperature resistance: >1000℃

Combustion performance: A1 level.

3. Excellent thermal insulation performance

Closed cell rate: >97%. (Reduce air convection heat transfer).

Minute thermal conductivity 0.045W/m·k (similar to EPS polystyrene board)

4. Low water absorption capacity

Keep the product free from moisture and mildew. It will not affect the insulation performance,

Ensure product safety and durability.

5. Lightweight and high strength

Density: 180kg/m³

Compressive strength: >0.35MPa

Meets strength requirements in transportation and engineering applications.

6. Good integrity after burning

The fire resistance time is more than 3 hours.

It maintains good integrity and does not pulverize after burning.

7. Freeze-thaw resistance

Mass loss rate <5%

Strength loss rate <20%. Therefore, the panel can maintain stable physical performance in complex weather changes.

8. Good sound insulation effect

The internal structure contains numerous independent air bubbles.

The sound absorption capacity is 5-7 times that of ordinary cement.

The sound insulation effect reaches 60db (140mm).

9. Good processability

The interface is high-quality, and it can be pasted directly after simple cleaning, and the effect is firm.

10. Low cost

Lifespan: 50 years (synchronized with building life)

There is no need to install the insulation board twice.

application

The insulation board can be used in external insulation projects in different climate zones

with different buildings.

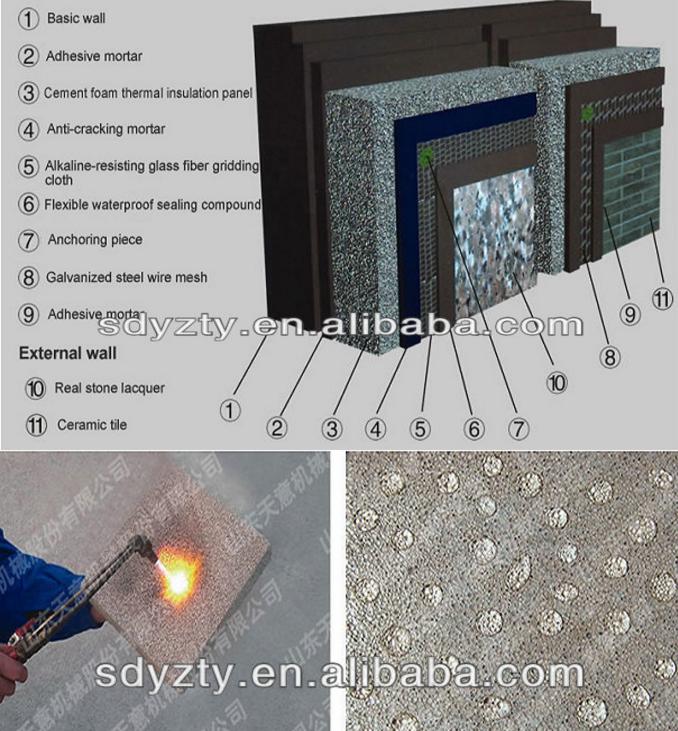

Construction structure of cement foam insulation board

A. Clear the basic wall

B. Putting mortar on the wall

C. Paste inorganic foam insulation board

D. Brushing polymer anti-cracking mortar on the board

E. Install anchor plate

F. Lay glass fiber on the entire wall, and apply anti-crack mortar for the second time

G. Paste exterior bricks (paint, ceramic tiles) according to the design requirements

Customer production site

construction process

our service

Company philosophy;

1. We guarantee that the trigger is brand new.

2. Based on natural materials, through high-tech research and development.

3. We strive to provide the best after-sales service, professional technical support, and try our best to meet your requirements

4. Sustainable green building system is our watchword

Certificate

main category

our workshop

exhibition

customer

about Us

Thank you for following Tianyi

Leo Yin (Sales Manager)

Mobile/Whatapp/WeChat: +8615905373355

Shandong Tianyi Machinery Co., Ltd.

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

-

Drywall gypsum panel/board production line

Other Products

-

$150000.00 / set

$150000.00 / set -

$5600.00 / set

$5600.00 / set -

$10000.00 / set

$10000.00 / set