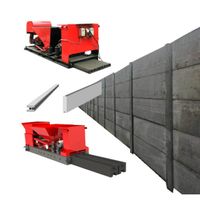

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Supplier: Guangxi Hongfa Heavy Machinery Co., Ltd. -

Region: Guangxi, China -

Contact: Mr David Yang -

Price: $15000.00 /piece -

Min. Order: 1 piece

| strength: | 0-100kw | feature: | automatic |

| Main selling points: | automatic | Origin: | Guangxi, China |

| Dimensions (L*W*H): | 2750*2504*1359mm/car | Applicable industries: | Building material store, manufacturing plant, home use, construction work |

| Production capacity: | 1 million square meters | Health status: | new |

| Warranty: | 5 years | Automatic level: | automatic |

| application: | Plastic EPS Sandwich Panel Making Machine | Showroom location: | Philippines, Brazil, India |

| weight: | 3.6 kg | brand: | Hongfa Plastic EPS Sandwich Panel Making Machine |

| Core component warranty: | 1 year | Core components: | PLC, bearings, gearboxes, motors, pressure vessels, water pumps |

| Mechanical test report: | if | Packaging Details: | Ride-on agricultural sprayer packaging: naked packaging or stretch film packaging or according to customer requirements |

| Voltage: | 220/380/440V | payment terms: | L/C, T/T |

| Package preview: | Marketing Type: | New Products 2021 | |

| Video shipment inspection: | if |

What is plastic EPS sandwich panel

FPB lightweight partition wall panels, also known as FPB lightweight composite sandwich wall panels (calcium silicate board polystyrene particle composite sandwich wall panels): it belongs to a new generation of building partition wall panels with two layers of calcium silicate boards on the surface. It is a solid wallboard composed of EPS polystyrene particles and various additives in the middle.

Advantages of plastic EPS sandwich panels

Answer: light weight

B: Good sound insulation effect

C: insulation

D: waterproof and fireproof

E: energy saving and environmental protection

F: easy construction

G: High strength without deformation.

EPS Concrete Lightweight Wall Panel Application

This polystyrene cement core sandwich wall panel now dominates the construction industry as the main wall building material in almost every field, such as: modern shopping malls, offices, commercial centers, schools, hospitals, factories, residential buildings, villas It is not only suitable for small projects such as private residential buildings, but also widely used for large projects such as high-rise buildings and modern commercial centers.

What type of panel are you looking for and want to make?

Hongfa provides complete production line equipment solutions. panel making machine/ concrete wall panel/ concrete wall machine/ precast concrete wall panel machine/ sandwich panel machine/ precast concrete machine/ eps panel making machine

Advantages of Hongfa Plastic EPS Sandwich Panel

1. Quickly install fiber cement board and aluminum mold. 2-3 people can complete 1 forming vehicle (30 pieces of 100mm thick plates) in 15 minutes.

2. 8 hydraulic cylinders ensure that the dispenser remains tight during curing. The cement hydration reaction (curing) will expand inside the machine, so the design of the machine is important for the panel plane.

3. The demoulding speed is fast, which does not affect the efficiency of mold installation.

4. Validation efficiency: 7 workers can get 900 square meters every 8 hours. (130 sqm/labor/shift)

5. Patent protection products

6. Labor-saving advanced technology

7. Double-sided opening, larger capacity

8.ISO9001-2015

9. It adopts touch screen control, automatic filling, electronic weighing, temperature control and material level control to realize automatic production.

10. Easy to maintain and easy to clean.

| Specification | ||||||

| The production capacity of a mold automotive EPS cement panel factory depends on the thickness and size of the panel. Model HFP530A | ||||||

| According to length X width: 2440*610mm/2270*610/3000*610mm | ||||||

| thickness | Parts/model car | m2/model car | Number of mold cars | m2/day | m2/year (300 days) | |

| 60mm | 40 | 59.5 | 1 | 59.5 | 17,850 | |

| 75mm | 36 | 53.5 | 1 | 53.5 | 16,050 | |

| 90mm | 32 | 47.6 | 1 | 47.6 | 14,280 | |

| 100mm | 30 | 44.6 | 1 | 44.6 | 13,380 | |

| 120mm | 26 | 38.6 | 1 | 38.6 | 11,580 | |

| 150mm | twenty two | 32.7 | 1 | 32.7 | 9,810 | |

| charging capacity | 5 cubic meters | |||||

| Finished wall panel size | 2440*610*60/75/90/100/120/150mm | |||||

| Hydraulic unit motor power | 2.2-5.5kw/model car | |||||

| Machine size | 3380*3200*2680mm | |||||

| installed capacity | 65-80kw | |||||

Other complete production line host

1. Mixing station

Hongfa mixing station is composed of mixer, mobile infusion device and polymerization system. It can automatically mix all raw materials and record every data of production. 3.6CBM capacity mixer ensures infusion efficiency. It only takes about 15 seconds to complete a 2440*610*100mm panel.

2. EPS expander

The EPS foaming machine is used for the foaming of raw polystyrene. The one-time foaming machine can make the EPS about 15-18kg/CBM, and the interval foaming machine can obtain the ratio of 9-11kg/CBM.

3. Stripping machine

The demoulding machine can directly pull out the cured board. Hongfa designed it based on 6 years of board manufacturing experience, so that the demoulding machine can be moved, and the mold can be installed immediately after demoulding without delaying time.

It can perform multiple tasks, and the efficiency is three times that of the traditional vertical manual semi-horizontal production line.

4. Recycling unit

The recovery unit can save everything in production, the waste slurry is settled in the underground mixer, and the cement and sand will be pumped into the mixer again for the next mixing cycle. Keep production clean, recycle waste and save costs.

5. Hollow plate unit

If you need hollow-core wall panels with a thickness of more than 150mm, Hongfa provides a complete system solution. Hollow core slabs are generally used for roofing, cladding, etc. without any load-bearing requirements.

6. Mobile slurry plunger pump unit

This machine is used for mobile hydraulic slurry pouring, after mixing all the raw materials in the mixer, then pour the slurry into the mobile

Container, which can be mixed and poured at the same time, guarantees that the slurry will not fall or the heavier material (sand or cement) will separate

From one of the lighters (EPS).

We have many successful production lines at home and abroad, such as...

packaging and delivery

Guangxi Hongfa Heavy MachineryFounded in 1990, the group is one of the largest block manufacturers and leading block suppliers in China. It has passed ISO9001-2000 certification, a "Guangxi Famous Brand" enterprise, and a member unit of China Block Association.

Hongfa Machinery Honorary Qualification

1. One of the top ten influential brands in China's brick and tile industry

2. Chinese enterprises honor contracts and keep promises

3. The quality and reputation of the dual-guarantee demonstration units

4. High-tech enterprises

5. Well-known trademark in China

6. Chinese Patent Star Enterprise

7. AAA grade credit enterprise

8. Consumer Satisfaction Unit

9. One of the top 100 brands in China's building materials industry

10. One of the top ten integrity units

11. Advanced Export Enterprise in Guangxi Province

12. Advanced unit of quality management

inquiry

Q: What is the MOQ?

A: 5 sets. According to economic benefit analysis

Q: Can I mix different designs?

Answer: Of course!

Q: Can I get a lower price if I order a large quantity?

A: Yes, the price is cheaper for larger size order.

Q: Can I add or remove items from my order if I change my mind?

A: Yes, but you need to tell us ASAP. If your order has already been completed on our production line, we cannot change it

Q: When will you ship the goods?

A: Usually 30-45 days after receiving your payment, but it can be negotiated according to the order quantity and production schedule.

Q: How about the quality guarantee period?

Answer: 5 years.

Q: How do you guarantee the production quality?

A: Our production quality follows China Construction Machinery Standard JGJ33-2012. We have more than 30 years experience in producing machines, QC team will inspect each shipment. We have a strict quality control system in the production process. We inspect each finished product 4 times before packing, third party inspection is acceptable.

If you are interested in any kind of products, please feel free to contact us.

contact information:

Foreign trade department: Jiffy

Guangxi Hongfa Heavy Machinery Co., Ltd.

URL: http://www.gxhongfa.cn

Tel: 0086-18260911699 WeChat

Fax: 0086-771-6036901

Factory Address: Linyi City, Shandong Province, China and Nanning City, Guangxi Province, China

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

-

Drywall gypsum panel/board production line

Other Products

-

Pig farm, sheep farm automatic prefabricated manure leakage board production line manufacturer price$25000.00 / set

Pig farm, sheep farm automatic prefabricated manure leakage board production line manufacturer price$25000.00 / set -

$10000.00 / set

$10000.00 / set