Titanium plasma coating machine, plasma ion PVD coating machine

-

Supplier: Guangdong HuiCheng Vacuum Technology Co.,Ltd. -

Region: Guangdong, China -

Contact: Ms. Lillian Yang -

Price: $8.00 /piece -

Min. Order: 1 piece

| Coating technology: | PVD vacuum ion coating; | Type: | Coating Production Line; |

| Supply Ability: | 200 Set/Sets per Year; | Place of Origin: | Guangdong China; |

| Condition: | New; | Type: | Titanium plasma coating machine; |

| Weight: | 5-9 tons; | Standard size: | 1250*1500mm, 1600*1800mm, 1800*2000mm, 2100*2100mm; |

| Coating: | Vacuum Coating; | Warranty: | 1 Year; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Applicable Industries: | Hotels,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Packaging Detail: | 20GP or 40HQ container; | Port: | shenzhen; |

| Brand Name: | HCVAC; | Voltage: | 380V; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Power(W): | 45KW; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Dimension(L*W*H): | customized; |

| Certification: | ISO9001; | Substrate: | steel,copper,iron,alloy,glass; |

| Detailed Description |

This is a ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate , great ionization rate, big ion energy,easy operation, low cost, large productive capacity, etc.It's the more advanced technology to replace traditional electroplating way.

Popular colors which could get by PVD:

Real gold an real rosegold coating

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

| FEATURES |

The equipment integrates the plasma treatment, high-end cathode magnetron sputtering, resistance evaporation coating equipment, large load rotation frame and the automatic control technique. It has the reliable work, good repeatability and consistency., fast deposition rate, high adhesion, fine film, etc. The coating film is dense and hardness with low friction coefficient, to keep the smoothness of original workpiece surface, good flexibility, hard to break and fall.

The equipment makes full automation of the coating technology come true. It uses the vacuum coating technique to coat on the surface of the base material. It has the features of low cost, high qualification rate, green environmental protection etc.

| APPLICATION |

It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film ( TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3and other decorative films etc.) and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of decorative coating for stainless steel, ceramic tile/cups, computer, mobile phone, watch& jewelry, sanitary, home appliance, hotel products etc.

| MACHINE PHOTOS |

| SAMPLE PHOTOS | |

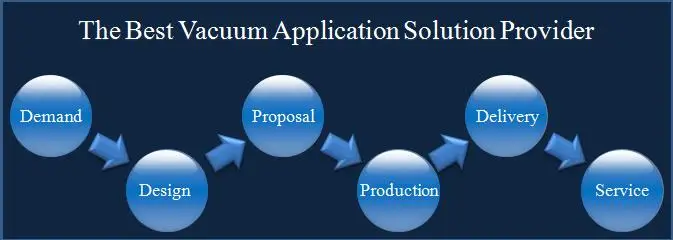

| ABOUT HUICHENG |

|

![]() Professional sales person and technical team to lead you to invest the project with best budget.Turn-key project offering.

Professional sales person and technical team to lead you to invest the project with best budget.Turn-key project offering.

![]() Quality control,high technology productivity to make sure the good quality machine production.

Quality control,high technology productivity to make sure the good quality machine production.

![]() One year warranty was provided since the date of delivery. In 1 year's warranty,For small problems about the machine,our profesional after-sales team will help to solve on line.For big problem,we will dispatch the engineer to your factory to solve problem.Large experienced engineer team is ready to serve all of you in the whole world.

One year warranty was provided since the date of delivery. In 1 year's warranty,For small problems about the machine,our profesional after-sales team will help to solve on line.For big problem,we will dispatch the engineer to your factory to solve problem.Large experienced engineer team is ready to serve all of you in the whole world.

| HUICHENG HONOR |

| PHOTO WITH CLIENTS & SUCCESSFUL CASE |

For more information, please feel free to contact us or visit our website: www.hcvacuum.com!

-

Powder Coating Industrial Oven Powder Coating Oven

-

Vacuum coating machine

-

Industrial grade chrome plating machine booth spray paint chrome plating machine

-

Gema Optiflex 2 Vibrating Box Feed Metal Electrostatic Powder Coating Machine Vibrating Powder Coating Machine

-

Stainless steel 10L spray chrome coating machine paint coating nano chrome plating machine

-

Hot Sale Classic Portable Manual Electrostatic Powder Coating Machine (WX-101)

-

High quality automotive hub sputtering vacuum coating machine

-

CE approved industrial powder coating curing oven gas electric stand for sale in China

-

Secondary Vacuum Coating Machine/Vacuum Coating Machine

-

Promote products Mirror spray chrome plating Fine surface spray chrome plating equipment