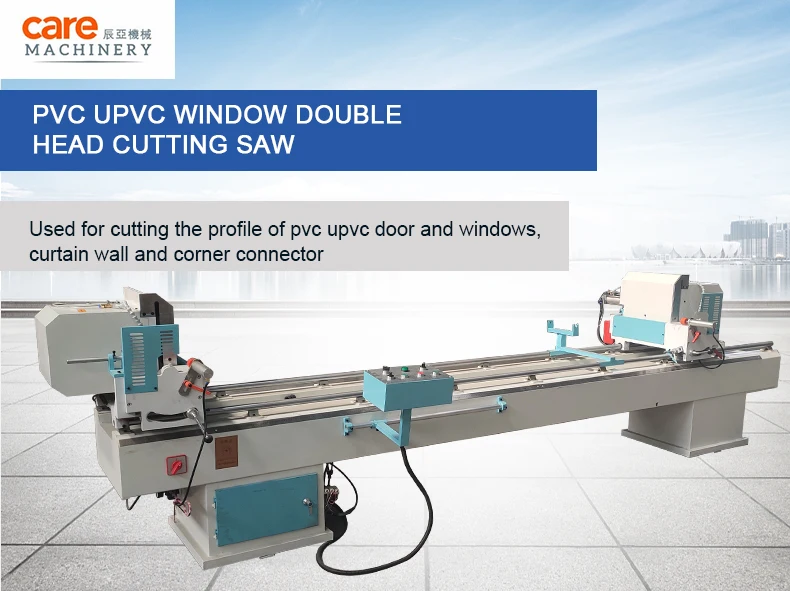

High precision pvc upvc profile window door double head mitre cutting saw machine

-

Supplier: Shandong Care Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Care Machine -

Price: $1200.00 /set -

Min. Order: 1 set

| Product name: | Pvc upvc profile window door double head mitre cutting saw machine; | Applicable Material: | PVC,UPVC,Aluminum; |

| Air consumption: | 50L/min; | After-sales Service Provided: | Online support; |

| Cutting width: | 100mm; | Cutting length: | 320~3700mm; |

| Voltage: | 380V; | Power supply: | 380v 50hz; |

| Applicable Industries: | Manufacturing Plant,Construction works ; | Power(W): | 3kw; |

| Port: | Qingdao Port; | Brand Name: | Care; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Saw blade specification: | 400x30; |

| Warranty: | 1 year; | Cutting height: | 150mm; |

| Dimension(L*W*H): | customizable; | Spindle rotary speed: | 2800r/min; |

| Production Capacity: | customizable; | Input Power: | 2x1.5kw; |

| Certification: | ce; | Air pressure: | 0.5~0.8mpa; |

| Supply Ability: | 20 Set/Sets per Month; | Key Selling Points: | Easy to Operate; |

| Packaging Detail: | 1, plastic stretch film coating; 2, steel pallet and plywood case package; 3, LCL or FCL by sea transportation;; | Weight: | customizable; |

High precision pvc upvc profile window door double head mitre cutting saw machine

Power supply | 380v 50hz |

Input Power | 2×1.5kw |

Spindle rotary speed | 2800r/min |

Cutting height | 150mm |

Cutting width | 100mm |

Air pressure | 0.5~0.8mpa |

Air consumption | 50L/min |

Saw blade specification | ∅400×∅30 |

Cutting length | 320~3700mm |

1. This machine is used for processing the aluminum and pvc profiles at angles of 45°,90°.

2. The swaying stable feeder is adopted.

3. The pneumatic driving system is used in profiles clamping and cutting.

4. It has the features of easy operation and high accuracy.

5. Imported carbides blade is of accurate processing and high accuracy.

6. Saw blade rotates smoothly due to high accuracy main spindle.

7. Uniform speed feeding and smooth motion are due to airdraulic damping cylinder.

8. It has feature of easy operation,reliable performance,advanced technique and convenient maintenance,etc.

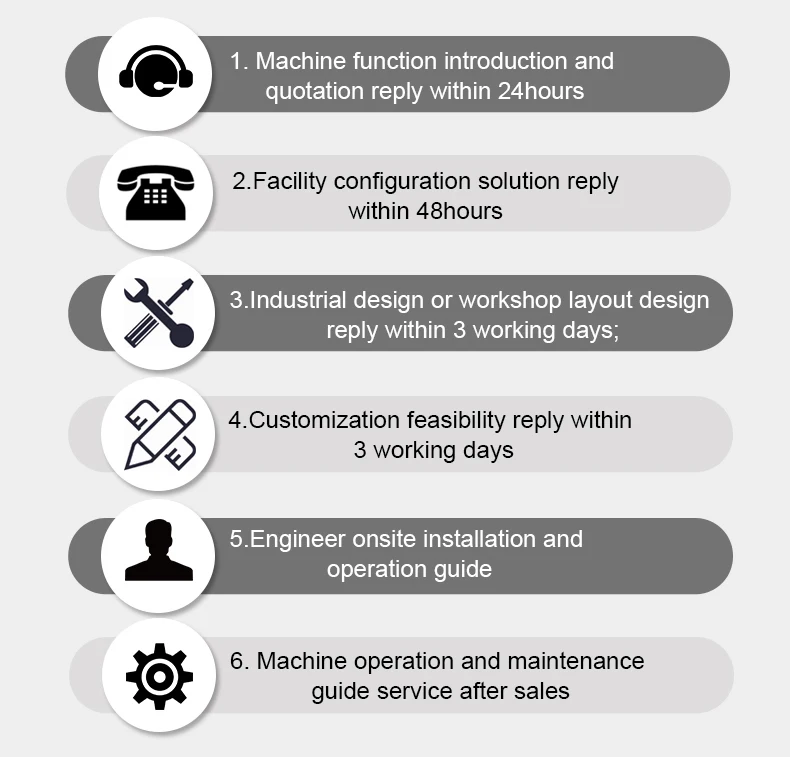

We are quality conscious company, and it’s just our origin to supply customers qualified machines. We are always trying to be the “Solution Expert of Glass Processing Facilities”. We not only supply complete glass processing facilities, but our professional engineer team also provide right facility configuration, accordingly customers’ various production requirements and estimated investment. And we’ll provide essential industrial design and technical guidance as well.

-

Aluminum profile cutting saw machine with digital instrument

-

Aluminum door and window back-to-back assembly table

-

PVC window double-sided seamless welding machine

-

90 or 45 degree aluminum angle cutting machine door and window aluminum profile cutting machine

-

Made in China High quality single head Upvc profile 45 degree angle miter saw

-

Popular machines for drilling aluminum door and window profiles

-

Aluminum Door and Window Frame Manufacturing Equipment Aluminum End Mill Machine Motor Offers Aluminum Cutting Machine

-

Made in China manufacturing door and window aluminum pneumatic punching machine

-

2021 Hot Sale Roller Door Roller Machine

-

Electric Portable Corner Cleaning Handle Tool for Small Workshop Upvc Door and Window Manufacturing

Other Products

-

$8500.00 / set

$8500.00 / set -

$5200.00 / set

$5200.00 / set -

$1450.00 / set

$1450.00 / set -

$2560.00 / set

$2560.00 / set -

$1200.00 / set

$1200.00 / set -

$900.00 / set

$900.00 / set -

$2700.00 / set

$2700.00 / set -

$8500.00 / set

$8500.00 / set -

$1200.00 / set

$1200.00 / set -

$4800.00 / set

$4800.00 / set