High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

-

Supplier: Ma Anshan Lvd Cnc Machine Tool Co.,ltd -

Region: Anhui, China -

Contact: Mr mu Tao -

Price: $5500.00 /set -

Min. Order: 1 set

| Local Service Location: | None; | Showroom Location: | None; |

| Warranty: | 5 years; | Port: | Shanghai; |

| X,Y Transmissions: | Hiwin Square rail,Rack Drive; | Working area: | 1300*2500MM; |

| Product name: | 500w 800w 1000w Sheet Metal Laser Cutting Machine With CE Certificate; | After-sales Service Provided: | Online support; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Supply Ability: | 200 Set/Sets per Month plasma cutting machines; |

| Brand Name: | LVD-CNC; | Laser power: | Hypertherm; |

| Certification: | CE; | Condition: | New; |

| Power: | 8.5KW; | Packaging Detail: | Wooden pallet for 500w plasma cutting machines; |

| After Warranty Service: | Online support; | Motor: | Stepless Motor; |

| Accuracy: | 0.02mm; | Key Selling Points: | Automatic; |

| Motor Type: | Stepless Motor; | Working Form: | Untouched arc striking; |

| Place of Origin: | Anhui China; | Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Home Use,Retail,Construction works ,Advertising Company; |

High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

Introduction of High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

| The machine adopt imported MAX Fiber laser source (500W,800W,1KW),dual driving ball screw moving system, fixed light-route with gantry style design, close-loop control with linear scale to make the cutting quality be perfectly match with the design.It very suits for fast and precision cutting on stainless steel and mild steel., even radian and sharp corner can be perfectly cut. | |

| Advantage | |

| |

| |

| 1.Low maintenance: fiber line transmission no need reflect lens, save maintenance cost; | |

| 2.Low power consumption: Energy saving and environmental friendly, lowest power consumption as the highest photoelectric conversion with Fiber source.Only 20%-30% consumption compared with other laser cutting system. | |

| 3.Low gas consumption: no need mixed gas for cutting, high pressure air can also cutting steel. | |

| 4.Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 plasma cutting machines. | |

| 5.Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours; | |

| 6.High efficiency for photoelectric conversion: Compare with CO2 plasma cutting machines, fiber plasma cutting machines have three times photoelectric conversion efficiency. | |

| 7.High cutting speed: cutting speed is 2-3 times than same power CO2 plasma cutting machines. | |

| 8.Easy operations: fiber line transmission, no adjustment of optical path. | |

| Applied Industries | |

| widely used in automobiles, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel and other industries | |

| Applied Material | |

iron plate,stainless steel plate,titanium plate,galvanized sheet, high speed steel,etc. | |

|

|

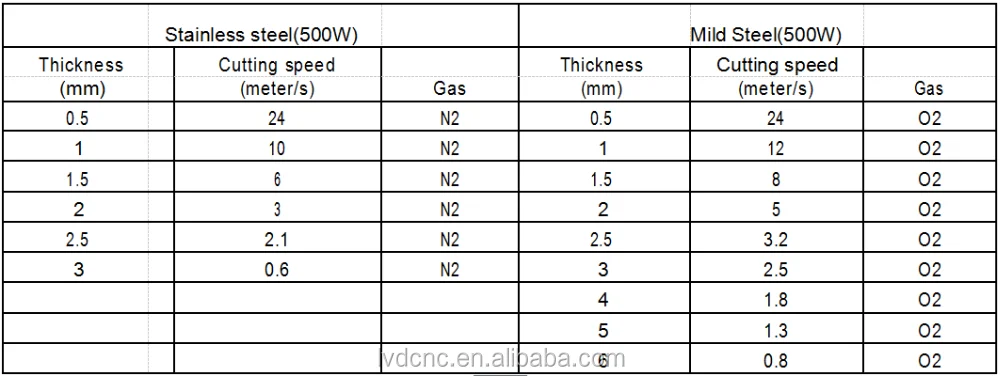

Cutting Data |

|

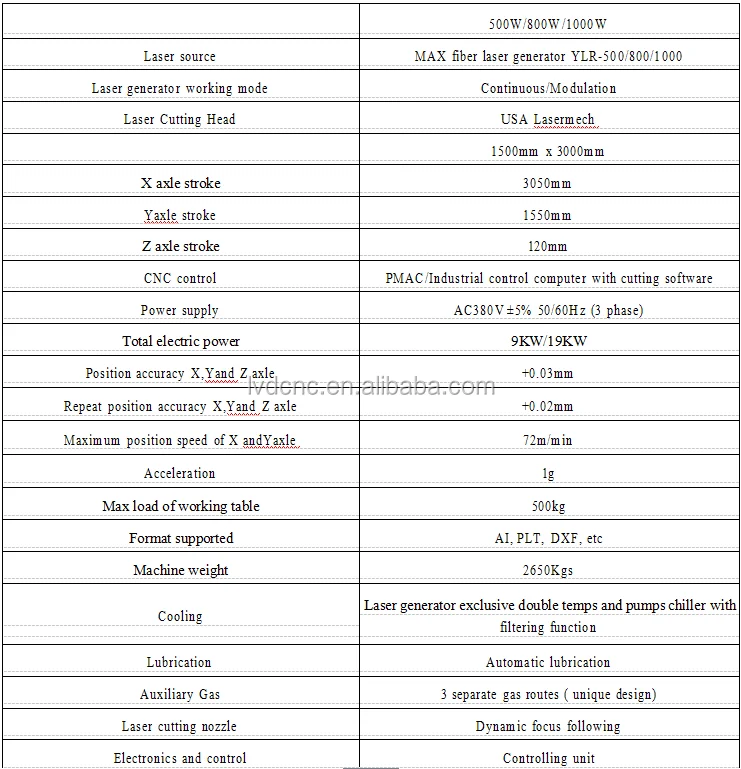

Specification Data

Mainly Components

Pictures of High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

Package Type: wooden package or can be adjust for the machine's safety.

Container Packaging: Wrapped in plastic to protect from getting wet.

| Packaging Details: | 1)before packing,the machine tool will be testing for 48 hours to ensure all the equipment is 100% qualitied. 2)before loading,stable package,professional and skilled loader reduce damage of product during transport. |

| Delivery Detail: | 30 days after payment |

High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

- Inquiring&consulting Service:24 hours online to reponse in 2 hours,provide solution in one day and solve complaint in 2 days.

- Technical Sevice: Engineers available to serive machinery overseas. We dispatch technician to customer's factory for installations and preoperation of machines.(costomers only need to pay airfare and hotel)

- Quality Guarantee Sevice:We provide 5 years warranty. We sign the agreement with detailed technical data.

- Other Service: A discount for a long cooperate and your visit to our factory is welcomed.

High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

ABOUT LVD-CNC

| LVD-CNC is totally focused on providing a line of products and support to maximize the productivity of ?Sheet metal machinery. |

| For over 16 years, LVD-CNC has specialized in CNC Press Brake, Guillotine and Laser Cutting and Punching to provide a complete sheet metal production workshop and improve accuracy of the productivity. |

| The company has a global network of over 15 appointed distributors trained to sell and service LVD-CNC machines. |

| LVD-CNC machines are built to our stringent set of design and quality standards in state-of-the-art manufacturing facilities. |

LVD-CNC product designs combine accuracy, speed, flexibility, durability, reliability and advanced technology to deliver machines with the highest performance-to-price ratio in the industry.

Others products of LVD-CNC 1.Press Brake Machine hot!!! 5.Rolling Machine hot!!! |

High Efficient Fiber Laser Cutting Machine Than Plasma Cutting Machine

Question 1

Are you a factory or trading company?

-We are a Amada Press Brake factory.

Question 2

Where is your factory located? How can I visit there?

-Our factory is located in Anhui Maanshan Province(next to Shanghai),China.You can fly to Shanghai airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

Question 3

How does your factory do regarding quality control?

-Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO,BV authentication.

Question 4

Trade Terms:

-1.Payment: T/T,Western Union,MoneyGram,PayPal; 30% deposits;70% balance before deliverying.

-2.Delivery Time: 20-60 days

-3.MOQ: 1 pcs

Question 5

Why choose us?

-1.We are China Leading Amada Press Brake Manufacturer.

-2.Alibaba Assessed 6 years Gold Supplier for Amada Press Brake.

-3.Inspected by the Inspection Institution of Bureau Veritas Certification.

-4.100% QC inspection Before Shipment.

-5.Best Quality & Best Service with Competitive price.

Question 6

How to contact us?

Rose Tian(Sale manager)

Moble(Whatsapp): 0086-18355531107

E-mail: rose(at)lvd-cnc.cn

Skype: rose-lvdcnc

♦Thanks for your reading, welcome to contact us:)

-

CNC Plasma Cutting Machine Metal Sheet Cutting Machine

-

TNC-3015 Cheap High Precision Desktop CNC Plasma Flame Cutting Machine

-

Customizable 220v Portable Powerful Inverter Air Alasma Cutter Cutting 70 For Stainless Steel Aluminum Carbon Steel Plasma

-

1500*3000 2000*4000mm China metal cutting/cnc plasma table/plasma cutting machine with rotation

-

Mini CNC Plasma Gantry CNC Plasma Cutting Machine Optional Worktable Competitive Price 3000*5000 Auto CAD Offer 300

-

High precision 1630 CNC plasma pipe cutting machine for metal pipe

-

cnc plasma cutting machine portable cnc plasma cutting machine

-

Sell CE Steel Cutting Machine Electric Profile Cutting Machine and J3G3 Cutting Machine

-

1530 Portable CNC Plasma Cutting Machine Metal Gas Cutting Machine

-

High Quality Low Price Portable CNC Plasma Cutting Machine KNCAM Brand CUT 5

Other Products

-

$1000.00 / set

$1000.00 / set -

$22000.00 / set

$22000.00 / set -

$10000.00 / set

$10000.00 / set