Scrap Metal Computer Motherboard Recycling Plant

-

Supplier: Zhengzhou Zhengyang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Hao -

Price: $30000.00 /set -

Min. Order: 1 set

| Material / Metal Processed: | e-waste metal and non-metal; | Showroom Location: | Indonesia,India,Thailand; |

| Applicable Industries: | E-waste proposal; | Packaging Detail: | Our Scrap Metal Computer Motherboard Recycling Plants are packed in wooden case or standard export container or as customer requirement.; |

| Supply Ability: | 20 Set/Sets per Month Scrap Metal Computer Motherboard Recycling Plant; | Capacity: | 200-300kg/h; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Function: | To recover metals from pcb boards; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Volatage: | 380V/50HZ; |

| Name: | Waste E-Waste Pcb Circuit Board Shredder Machine; | Port: | Qingdao Port; Shanghai Port; As your request; |

| Weight (KG): | 9500; | Place of Origin: | Henan China; |

| Brand Name: | SUNY; | Certification: | CE ISO; |

| Weight: | 9.5T; | Key Selling Points: | Sustainable; |

| Power (kW): | 100; | Warranty: | 1 year; |

| Condition: | New; | Application: | E-waste/PCB treatment; |

| Local Service Location: | Malaysia,Philippines,India; | Payment Terms: | L/C,D/P,T/T,Western Union,MoneyGram,Cash/Alibaba trade assurance; |

| Power: | 100KW; | Color: | Customer's Requirement; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

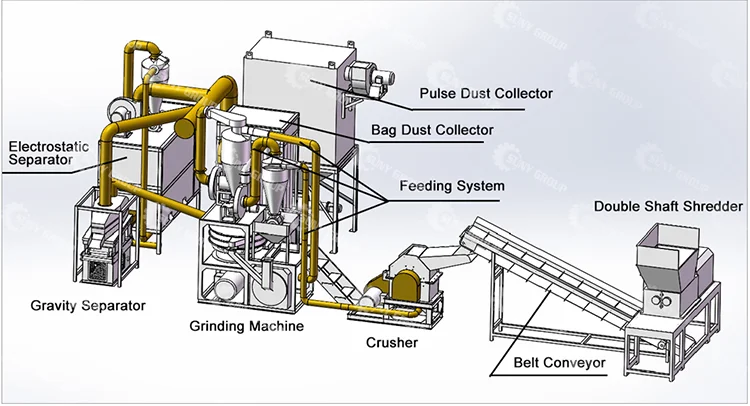

Scrap Metal Computer Motherboard Recycling Plant

PRODUCT APPLICATION

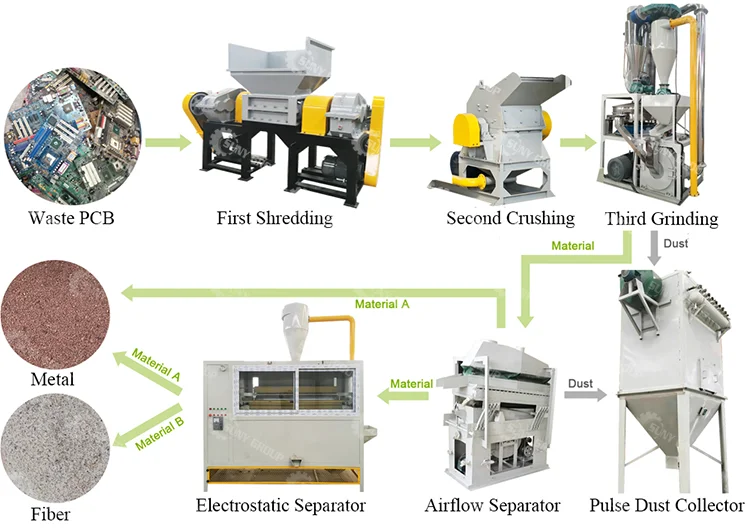

Scrap Metal Computer Motherboard Recycling Plant is used to recycle all kinds of Printed Circuit boards, such as the computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the separation of leftover material of the mixed metal and nonmetal materials.

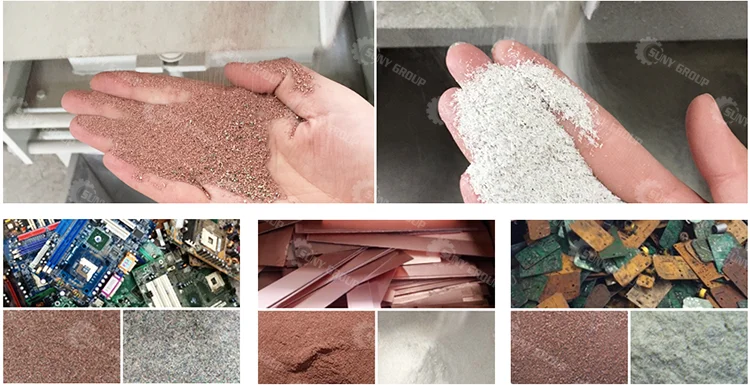

FINAL PRODUCTS

Because of the high value of the metals, fiber and resin, there is no doubt that this plant not only help to change waste into treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

| Model | Power (Kw) | Weight (Ton) | Capacity (Kg/H) | Dimension (m) |

| ZY-PCB300 | 102 | 15 | 200-300 | 20*5*5 |

| ZY-PCB500 | 134 | 20 | 400-500 | 25*6*5 |

| ZY-PCB800 | 194 | 30 | 600-800 | 30*6*5 |

| ZY-PCB1000 | 238 | 40 | 800-1000 | 35*8*5 |

1. Working voltage:380±10V(415V ,440V also can be customized);

2. Working temperature:0 - 55 degree;

(If you want more detailed parameters and quotations, please contact us)

-

V-S30 Fully Automatic Scrap Copper Wire Granulator Recycling Machine Copper Recycling Machine

-

High performance small copper cable shredder mini cable shredder used copper wire shredder

-

High-quality PCB recycling equipment/PCB dismantling machine

-

BSGH Mini Cable Granulator Waste Cable Wire Separator Recycling Machine at 220 V with the most advanced technology and good quality

-

industrial iron ore crusher plant price

-

Shredder Double Shaft Shredder, Shredder, Waste Plastic Shredder

-

2022 Best Selling Cable Wire Granulator Grid Grinding Separator Recycling Machine

-

Factory direct sales metal pipe bender round pipe bender iron pipe bender

-

Double shaft scrap metal shredder used car shredding scrap metal shredder

-

Copper Wire Pelletizer Splitter/Small Copper Wire Pelletizer

Other Products

-

$5000.00 / set

$5000.00 / set -

$12000.00 / set

$12000.00 / set -

$5000.00 / set

$5000.00 / set -

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set -

$20000.00 / set

$20000.00 / set -

$700.00 / set

$700.00 / set -

$50000.00 / set

$50000.00 / set -

$40000.00 / set

$40000.00 / set -

$5000.00 / set

$5000.00 / set -

$30000.00 / set

$30000.00 / set