Scrap Wood/Iron/Rubber Plastic Metal Crusher Machine Price

-

Supplier: Zhengzhou Zhengyang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Hao -

Price: $20000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Type: | Twin Shaft Shredder; |

| Capacity: | 600-1200Kg/h; | Port: | QINGDAO Port; |

| Input Materials: | Iron Steel Metal Scraps; | Warranty: | 1 year; |

| Key Selling Points: | High Productivity; | Feature: | Free training for Blade Changing; |

| Blade material: | 9CrSi/D2/SKD-11; | Power (kW): | 110; |

| Weight (KG): | 7000; | Packaging Detail: | A layer of metal wraps to protect the plastic shredder from dust, moisture and corrosion. Wooden case as the outside package for our Scrap Wood/Iron/Rubber Plastic Metal Crusher Machine Price; |

| Color: | As Customized; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,Credit Cards; |

| Brand Name: | Suny Group; | Supply Ability: | 50 Set/Sets per Month; |

| Output Size: | 30-70mm; | Applicable Industries: | Machinery Repair Shops,Manufacturing Plant,Energy & Mining,Crusher Machine; |

| Material / Metal Processed: | Stainless Steel,Brass / Copper,ALLOY,Carbon Steel,Aluminum; | Place of Origin: | Henan China; |

| Condition: | New; | Advantage: | Precise Processing Blades; |

| Application: | Shred Scrap Materials; | Name: | Scrap Wood/Iron/Rubber Plastic Metal Crusher Machine Price; |

Scrap Wood/Iron/Rubber Plastic Metal Crusher Machine Price

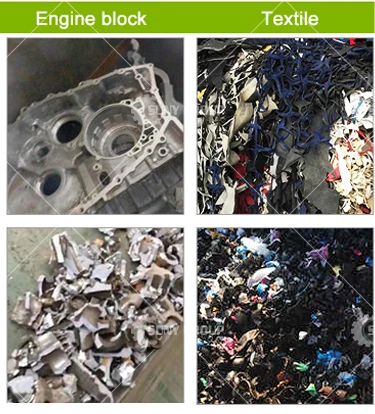

1. All kinds of hollow containers: plastic beverage cans, plastic buckets, iron drums, packing boxes, packing drums.

2. Used household appliances: TV, washing machine, refrigerator shell.

3. Pipe material: large pipe, pipe fitting and PE pipe.

4. Used templates: wooden pallets, plastic pallets and forklifts.

5. Used tires: car tires, truck tires.

6. Scrap metal: automobile housing, aluminum alloy, scrap cast aluminum parts, engine housing, lead and steel plates with thickness below 5mm.

7. Cooking garbage, living garbage, RDF derivative, medical waste, biological orange pole, garden garbage.

8. Glue head material, paper mill rope.

1. Shaft, moving blades, fixed blades, reducer, motors, feeding hopper, discharge port, electric control cabinet, control panel, screen, roller, knives holder, ect.

2. After shreddering, the dimension of most large plastic or other material will reduce 30%, some material dimenison after shreddering can up to 50%.

(We have arranged many videos. Please contact us freely if you need.)

We design the blades with different hooks, and the thickness of blades for different materials are different, the range is 10mm-80mm. Blade quality have 9CrSi, Cr12MoV, SKD-II, D2 etc.

The main body of the shredder is welded with high quality steel plate to eliminate stress treatment/integral machining to ensure the stability of the equipment under heavy load for a long time.

Knife shaft is is made of special special alloy tool steel forging blank, precision machining, multiple heat treatment, and reasonably provided powerful power for cutting, increase service life.

Our double shaft shredder adopts button control, easy to operate, set up, stop, reverse, overload protection and other functions.

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customers' material;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

| Model | ZY-D600 | ZY-D800 | ZY-D1000 | ZY-D1200 |

| Motor power (kw) | 7.5+7.5 | 15+15 | 18.5+18.5 | 30+30 |

| Capacity (kg/h) | 500-600 | 700-800 | 800-1000 | 1000-1200 |

| Cutter (pcs) | 22 | 30 | 30 | 36 |

| Shredding room size (mm) | 600x430 | 800x430 | 1000x500 | 1000x580 |

| Weight (kg) | 2300 | 3300 | 5000 | 6800 |

-

V-S30 Fully Automatic Scrap Copper Wire Granulator Recycling Machine Copper Recycling Machine

-

High performance small copper cable shredder mini cable shredder used copper wire shredder

-

High-quality PCB recycling equipment/PCB dismantling machine

-

BSGH Mini Cable Granulator Waste Cable Wire Separator Recycling Machine at 220 V with the most advanced technology and good quality

-

industrial iron ore crusher plant price

-

Shredder Double Shaft Shredder, Shredder, Waste Plastic Shredder

-

2022 Best Selling Cable Wire Granulator Grid Grinding Separator Recycling Machine

-

Factory direct sales metal pipe bender round pipe bender iron pipe bender

-

Double shaft scrap metal shredder used car shredding scrap metal shredder

-

Copper Wire Pelletizer Splitter/Small Copper Wire Pelletizer

Other Products

-

$5000.00 / set

$5000.00 / set -

$12000.00 / set

$12000.00 / set -

$5000.00 / set

$5000.00 / set -

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set -

$700.00 / set

$700.00 / set -

$50000.00 / set

$50000.00 / set -

$40000.00 / set

$40000.00 / set -

$30000.00 / set

$30000.00 / set -

$5000.00 / set

$5000.00 / set -

$30000.00 / set

$30000.00 / set