PTS controller over fuel dispensers and ATG systems

-

Supplier: TECHNOTRADE LTD -

Region: China -

Price: $550.00 /unit -

Min. Order: 1 unit

| Payment Terms: | T/T; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service; |

| Weight: | 0.12 kg; | Certification: | CE certificate; |

| Voltage: | 12 V DC; | Packaging Detail: | Cardboard box; |

| Brand Name: | PTS controller; | Warranty: | 1 year; |

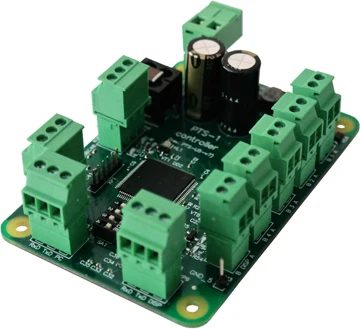

| Supply Ability: | 10000 Piece/Pieces per Year; | Dimension(L*W*H): | 120 x 85 x 20 mm; |

| Condition: | New; | Place of Origin: | Ukraine; |

| Port: | Kyiv, Ukraine; |

Purpose

PTS controller over fuel dispensers and ATG (automatic tank gauge) systems for petrol stations serves as a protocols converter. It knows communication protocols of a great variety of fuel dispensers and ATG probes and allows control over any of them in exactly the same way using its own input communication protocol. POS system (cash register, payment terminal) should not matter what is the brand of fuel dispenser or ATG system connected – it simply communicates to the PTS controller the same way regardless the brand of fuel dispensers and ATG systems used, PTS controller undertakes all work on communication with fuel dispensers and ATG systems using their native communication protocol and takes into account all their peculiarities.

This completely simplifies work for a POS system developer: by having implemented input common communication protocol of PTS controller the POS becomes able to provide control over any of fuel dispensers and ATG systems supported by PTS controller. PTS controller itself converts input communication protocol into proprietary communication protocols of fuel dispensers and ATG systems. Thus the time required for development of POS system for petrol stations is significantly reduced.

PTS controller can be called a forecourt controller and can be used together with POS systems, cash registers, OPTs (outdoor payment terminals) and other control systems for petrol stations in order to provide control over fuel dispensers, LPG (liquified petroleum gas) dispensers, CNG (compressed natural gas) dispensers and various brands of ATG systems at petrol stations and storage depots.

PTS controller is supplied with a rich set of APIs (application programming interfaces) developed under most popular programming languages and environments in order to provide comfortable and quick implementation of the PTS controller into control systems for petrol stations (POS system, cash register, OPT terminal, etc).

PTS fuel pump controller can simultaneously control up to 16 fuel dispenser sides (fueling places). PTS controller has 4 independent pump ports, each of them can be programmed to its own communication protocol and baud rate, thus PTS controller provides communication with connected dispensers simultaneously using up to 4 various communication protocols. Each PTS controller pump port can connect up to 16 fueling places maximum.

PTS controller can simultaneously control up to 16 ATG probes (gauges) (separate probes or probes connected to ATG systems / consoles) that use up to 3 various communication protocols and baud rates (each of the probe ports can be adjusted to a separate communication protocol and baud rate and connect up to 16 ATG probes maximum).

PTS controller allows a possibility to lead management over the same fuel dispensers from several POS systems and share ATG probes measurement values between several interconnected PTS controllers. Thus every interconnected PTS controller is able to provide control over any of the connected fuel dispensers and know ATG system measurement data of every other interconnected PTS controller.

PTS controller supports 90 types of fuel dispensers brands of various manufacturers, between which you can find: Wayne Dresser Europe, Wayne Dresser Brasil, Gilbarco Veeder Root, Tokheim, Nuovo Pignone, Wayne Pignone, Tatsuno Japan, Tatsuno Europe, Tatsuno Rus, Tokico, Bennett, Petrotec, Salzkotten, FAS, Adast, MM Petro ZAP, Emgaz Dragon, Galileo, Kraus, Welma, PEC (Gallagher), Develco, Logitron, Kalvacha, Safe, Wayne Meksan, Mekser, Mepsan, 2A, Petposan, Petrolmeccanica, Batchen, Email, EuroPump, Baransay, Sanki, Korea EnE, LG EnE, SOMO Petro, HongYang, Blue Sky, GreenField, Falcon, Dong Hwa Prime, EPCO, Slavutich, Shelf, UniCon, UniGaz and others.

PTS controller supports more than 25 types of automatic tank gauge (ATG) systems of various manufactures (Gilbarco Veeder Root, OPW, Hectronic, Struna, PetroVend, Start Italiana, Fafnir, Assytech, VEGA, Windbell and others).

PTS controller is CE approved and has all corresponding test reports.

Features and benefits

- Supports over 70 communication protocols of fuel dispensers and ATG systems. List of supported communication protocols is constantly growing. A wide range of international protocols as Wayne DART, Gilbarco 2-wire, Tokheim, Tatsuno are included. Single firmware of PTS controller contains all available communication protocols for fuel dispensers and ATG systems.

- Unified approach to management over any forecourt equipment - using PTS controller control over any supported fuel dispenser or ATG system is done in exactly the same way by the management system (POS system, cash register, OPT terminal, etc). PTS controller has a single common communication protocol. Thus having once implemented the protocol into the management system (or its API) the management system will be able to provide control over any of the supported fuel dispensers and ATG systems in exactly the same way.

- Real-time control over fuel dispensers and ATG systems. PTS controller provides a hardware solution for stable and reliable operation of forecourt equipment.

- Scalability - PTS controller provides control over up to 16 dispenser sides, in case of necessity several PTS controllers can work simutaneously.

- Possibility to provide control over same fuel dispensers from several POS systems and receive data on ATG measurements from any interconnected PTS to each POS system - PTS controllers, installed near each of the POS systems, can be interconnected with each other allowing each of the POS systems to provide control over each of the connected fuel dispensers or monitor its state and to have data measurements of ATG systems connected to any of the interconnected PTS controllers.

- Rich set of interface converters for connection to fuel dispensers - PTS controller has output pump ports in RS-485 interface so can be directly connected to fuel dispensers with this type of interface. Other dispensers having communication interface of 2-wire current loop, 3-wire current loop, 4-wire current loop, RS-232 interface are connected to PTS controller through special interface converters.

- Rich software API for developers - PTS controller is supplied with full API (application programming interfaces) and open-source test applications for common programming languages and operation platforms: C, C++, C#, Delphi, Java, Python, Visual Basic, COM-object.

- "All in one" configuration tool for PTS controller: one configuration utility provides configuration of its pump and probe ports, internal parameters, reads version, makes firmware updates, captures logging from any channel and makes self-diagnostics of the PTS controller.

- Easy firmware updating - All new firmware updates are available for download to all existing customers. Firmware update process takes about 1 minute. Easy way to back up and restore PTS controller configuration between updates.

- Logging of operation - in order to remove problematic situations of PTS controller communication with any forecourt equipment logging of communication exchange without interrupting PTS controller operation is available, which allows quick search and elimination of any found problems.

- Self-diagnostics of operation - easy and quick built-in diagnostics of PTS controller operation: CPU, memory, RS-232 and RS-485 interfaces, DIP-switches.

- Constant software updates - PTS controller firmware is constantly being improved, new protocols are being added and latest updates are always available for download to all customers.

- Support by developers for developers - 24 hours support for all customers of PTS controller on any standing issues.

- Credit-card size and suits to any dimension for installation inside master systems.

Technical characteristics

| PARAMETER | VALUE |

|---|---|

| Power supply voltage | 12 V DC |

| Current consumption | 400 mA max |

| Temperature range | from -40°C to +80°C |

| Weight | 120 g |

| Overall dimensions | 120 x 85 x 20 mm |

Supported communication protocols

Fuel dispensers communication protocols

Baud rate is configured for each pump port in PTS controller independently on the used communication protocol.

Some dispensers may demand using interface converter boards to RS-485 interface (depends on electronics of used pumphead in dispenser).

| ## | FUEL DISPENSER BRAND | PROTOCOL NAME |

|---|---|---|

| 1 | 2A | S4-Dart |

| 2 | ACTRONIC | PEC Pump Communication Protocol |

| 3 | ADAST (ADAMOV SYSTEMS) | Adast EasyCall |

| 4 | AG WALKER | SPDC-1, MPDC-1 |

| 5 | AGIRA | PEC Pump Communication Protocol, PumpControl, Develco |

| 6 | ANGI International | Gilbarco Two-Wire |

| 7 | ARIEL | PumpControl |

| 8 | ASPRO | PumpControl, Develco, Coritec |

| 9 | ASSYTECH | Dart |

| 10 | ASTRON | TiT UniPump |

| 11 | AZT | AZS 2.0 |

| 12 | BARANSAY | Gilbarco Two-Wire |

| 13 | BATCHEN | Gilbarco Electroline, Gilbarco MPP, PumpControl, Maser, PEC Pump Communication Protocol |

| 14 | BENNETT | Bennett pump dispenser protocol (current loop), Bennett pump dispenser protocol (RS-485 Fleet), Bennett pump dispenser protocol (RS-485 Retail) |

| 15 | BLUE SKY | Blue Sky 6-6-4 protocol, Blue Sky 8-8-6 protocol, LT protocol, LY protocol, JP protocol |

| 16 | CENSTAR | Censtar protocol |

| 17 | CFT Clean Fuel | Gilbarco Two-Wire |

| 18 | COMPAC | PEC Pump Communication Protocol, Gilbarco Australia |

| 19 | CORITEC | Coritec |

| 20 | DATIAN MACHINES | WS 16 communication protocol |

| 21 | DEVELCO | Develco |

| 22 | DONG HWA PRIME | Prime pump interface |

| 23 | EAGLESTAR | Eaglestar |

| 24 | EMGAZ DRAGON | Marconi PumaLAN |

| 25 | EPCO | Epco protocol specification |

| 26 | ESIWELMA | Marconi PumaLAN |

| 27 | EUROPUMP | S4-Dart |

| 28 | FALCON LPG | Falcon |

| 29 | FORNOVO GAS | Marconi PumaLAN |

| 30 | FUELQUIP | PEC Pump Communication Protocol |

| 31 | FUELSIS | S4-Dart |

| 32 | GALILEO | PumpControl |

| 33 | GERKON | TiT UniPump |

| 34 | GILBARCO | Gilbarco Two-Wire, Extended Two-Wire Appendix |

| 35 | GREENFIELD | Gilbarco Two-wire |

| 36 | HITACHI | SS-LAN protocol |

| 37 | HONG YANG | HongYang FZ-protocol, HongYang 886 communication protocol, HongYang 886 MPD communication protocol |

| 38 | IMW | PumpControl, Tokheim UDC |

| 39 | INTERMECH | PEC Pump Communication Protocol |

| 40 | KALVACHA | Kalvacha |

| 41 | KIEVNIIGAZ | TIT UniGaz |

| 42 | KOREA ENE | EnE Dispenser POS protocol |

| 43 | KPG-2 | TIT UniGaz |

| 44 | KRAUS | MNET design specification, Gilbarco Two-wire |

| 45 | KWANGSHIN | KS-NET PROTOCOL |

| 46 | LANFENG | RS–232 protocol, RS–485 protocol, SS-LAN protocol |

| 47 | LG ENE | EnE Dispenser POS protocol |

| 48 | LOGITRON | Marconi PumaLAN |

| 49 | MASER | Maser, Gilbarco Two-wire |

| 50 | MEKSAN / WAYNE SU86 | Wayne Dart |

| 51 | MEKSER | S4-Dart |

| 52 | MEPSAN | S4-Dart |

| 53 | MIDCO | Midco Proprietary Pump Protocol (versions 3.10, 3.11, 3.12) |

| 54 | MM PETRO (ZAP) | MM PETRO ZAP RS-485 |

| 55 | MOTOGAZ | PumpControl |

| 56 | MS GAS | SK protocol |

| 57 | NARA | AZT 2.0 |

| 58 | NUOVA MIGAS | Dart |

| 59 | NUOVO PIGNONE | Nuovo Pignone RS-485, Nuovo Pignone Current Loop 4-wire, Wayne Dart |

| 60 | PEC (GALLAGHER FUEL SYSTEMS) | PEC Pump Communication Protocol, Gilbarco Australia |

| 61 | PETPOSAN | S4-Dart |

| 62 | PETROEQUIP | Lanfeng protocol |

| 63 | PETROMECCANICA | Wayne Dart |

| 64 | PETROTEC | Petrotec HDX protocol |

| 65 | PROWALCO | SPDC-1 / MPDC-1, SPDC-2 / MPDC-2, Salesmaker & ICON |

| 66 | PUMP CONTROL | PumpControl |

| 67 | REAL-TECH | Blue Sky, SS-LAN |

| 68 | RIX | PEC Pump Communication Protocol |

| 69 | SAFE | Safe PMII Graf, PumpControl |

| 70 | SALZKOTTEN | ER3 Data interface, Gilbarco Two-Wire, Marconi Logitron PumaLAN |

| 71 | SANKI | Sanki common communication protocol, Sanki communication protocol for CIS countries |

| 72 | SEA BIRD | Blue Sky |

| 73 | SHELF | Shelf |

| 74 | SCHEIDT & BACHMANN | T02, V11 |

| 75 | SHIBATA | SS-LAN |

| 76 | SLAVUTICH | Slavutich FD-Link |

| 77 | SOMO PETRO | POS protocol |

| 78 | STAR | HongYang 886 communication protocol, HongYang 886 MPD communication protocol |

| 79 | TATSUNO (JAPAN) | Tatsuno SS-LAN, Extended Digits Number protocol |

| 80 | TATSUNO EUROPE (FORMER BENC) | Tatsuno Benc PDE, Logitron PumaLAN |

| 81 | TEKSER | Wayne Dart, Wayne US Current Loop |

| 82 | TOKHEIM | Tokheim Controller-Dispenser Communication protocol (UDC), Logitron PumaLAN |

| 83 | TOKHEIM INDIA | TQCL serial communication protocol |

| 84 | TOKICO | Tokico SS-LAN |

| 85 | TOMINAGA | Tominaga SS-LAN |

| 86 | TOPAZ | TOPAZ Electro, Iskra ver. 1.72 |

| 87 | TRANSPONDER | PEC Pump Communication Protocol |

| 88 | UCAR ELEKTRIC | S4-Dart |

| 89 | UNICON-TIT | TIT UniPump |

| 90 | VANZETTI | Logitron PumaLAN |

| 91 | WAYNE DRESSER | Wayne Dart, Wayne US Current Loop |

| 92 | WAYNE PIGNONE | Wayne Dart |

| 93 | YENEN | S4-Dart, Maser |

| 94 | ZCHENG GENUINE MACHINES | Zcheng communication protocol |

Automatic tank gauge (ATG) systems communication protocols

Communication parameters (baud rate, parity control, data and stop bits) are configured for each probe port in PTS controller independently on the used communication protocol.

| ## | ATG SYSTEM BRAND | PROTOCOL NAME |

|---|---|---|

| 1 | ACCU | PD-300 Communication Protocol |

| 2 | ASSYTECH | Assytech |

| 3 | DUT-E | COM protocol |

| 4 | EAGLESTAR | Modbus RTU, Smart-probe communication protocol |

| 5 | EBW | Gilbarco Veeder Root |

| 6 | ENRAF | Enraf Height protocol, Enraf Volume protocol |

| 7 | FAFNIR | Fafnir VISY-Quick, Gilbarco Veeder Root |

| 8 | FRANKLIN FUELING | Gilbarco Veeder Root |

| 9 | GAMICOS | GLT622 console communication protocol |

| 10 | GILBARCO VEEDER ROOT | Gilbarco Veeder Root |

| 11 | HECTRONIC | Hectronic HLS |

| 12 | HUMANENTEC | 520S Communication Protocol |

| 13 | INCON | Gilbarco Veeder Root |

| 14 | LABKO | Labkotec POS interface protocol |

| 15 | MTS ATG SENSORS | MTS USTD |

| 16 | OMNICOMM | COM protocol |

| 17 | OMNTEC | Gilbarco Veeder Root |

| 18 | OPW | Gilbarco Veeder Root |

| 19 | PETRO VEND | PETROVEND4 |

| 20 | QINGDAO GUIHE | Gilbarco Veeder Root, Qingdao Guihe MODBUS RTU |

| 21 | START ITALIANA | Start Italiana SMT/XMT, Gilbarco Veeder Root |

| 22 | STRUNA | Struna Kedr spec. 1.4 |

| 23 | UNIPROBE | Uniprobe |

| 24 | VEGA | Vega ASCII protocol |

| 25 | WINDBELL | Windbell smart-probe communication protocol |

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.

Connection to fuel dispensers

PTS controller can simultaneously control up to 16 fuel dispenser sides (fueling places). PTS controller has 4 independent pump ports and each of them can be programmed to its own communication protocol and baud rate, thus PTS controller provides communication with connected dispensers, simultaneously using up to 4 various communication protocols. Each PTS controller pump port can connect up to 16 fueling places maximum.

Connection to ATG systems

PTS controller can simultaneously control up to 16 ATG probes (gauges) (separate probes or probes connected to ATG systems/consoles) that use up to 3 various communication protocols and baud rates (each of the probe ports can be adjusted to a separate communication protocol and baud rate and connect up to 16 ATG probes maximum.

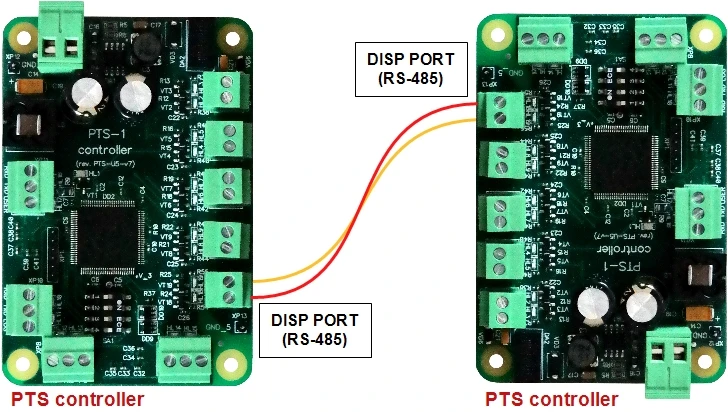

Multi POS systems operation

PTS controller allows a possibility to lead management over the same fuel dispensers from several POS systems and share ATG probes measurement values between several interconnected PTS controllers. Thus every interconnected PTS controller is able to provide control over any of the connected fuel dispensers and know ATG system measurement data of every other interconnected PTS controller.

If a necessity arises to organize several working places at petrol station (several POS systems) each of the POS systems should have its own PTS controller connected. PTS controllers should be interconnected with each other through a dispatcher PTS port (DISP channel on RS-485 interface) and with fuel dispensers. Thus control over each fuel dispenser at petrol station can be made from every POS system and each PTS controller will know measurement data of every ATG probe connected to any of the interconnected PTS controllers. During authorization of a fuel dispenser from one POS system the fuel dispenser becomes locked by PTS controller of this POS system and while it is locked all other POS systems cannot control given fuel dispenser, they can only monitor its current state. When operation of given POS system is finished with given fuel dispenser, PTS controller of this POS system unlocks the fuel dispenser and it becomes commonly available to all other PTS controllers, which makes it possible to be controlled (locked) by any of the PTS controllers connected to other POS systems.

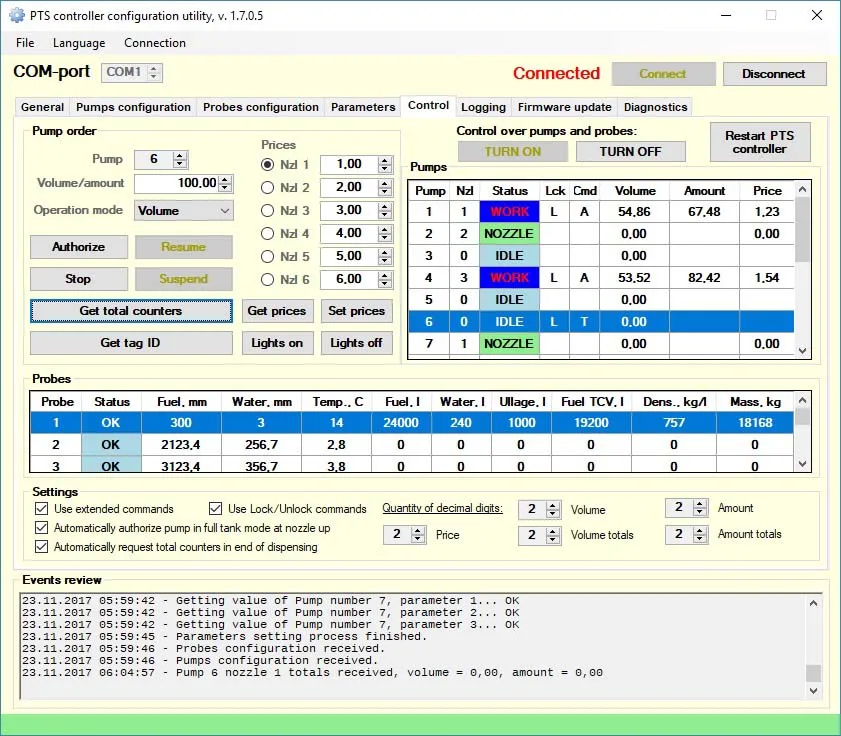

PTS controller configuration utility

PTS controller configuration utility is an open source application, which provides the following operations with PTS controller:

- Configuration of pump port and probe port of PTS controller

- Configuration of pump protocol, ATG, and PTS controller parameters

- Provision of control over the pumps and monitoring measurement values of ATG systems like real POS system

- Saving of all PTS controller configuration to file and restoring of all configuration from file

- Updating of PTS controller firmware

- Logging of PTS controller communication on selected channel

- Self-diagnostics of PTS controller:CPU, memory, RS-232 and RS-485 interfaces, DIP-switches

- Reading of current PTS controller firmware version: display of firmware date, number and supported communication protocols

- Direct connection of PTS to POS system or connection through fiscal module: possibility to configure PTS controller via direct connection of PTS controller to POS or connection through fiscal module

- Multilanguage support: easy addition of new languages to the utility, all languages are stored in XML-file, which is easy to edit

Developers' API, source codes and examples

PTS controller for developers is supplied together with a rich set of API (application programming interfaces) for commonly used programming languages and operation platforms:

- C and C++ - API for communication with a PTS controller through a COM-port, documentation and examples of application in source codes under Windows OS and Linux operating systems

- C#:

- open source library, which includes classes, methods and properties for communication with PTS controller for provision of control over dispensers and ATG systems and configuration of PTS controller

- open source PTS controller configuration and testing utility

- open-source utility for testing and indication of all operations provided by the PTS controller, allows to perform all operations with the PTS controller

- open source fully-functional application for provision of control over up to 8 pumps and 4 ATG systems by the PTS controller, allows to perform all operations with the PTS controller

- Delphi - API for communication with a PTS controller through a COM-port, documentation and examples of application in source codes

- Java:

- open source library, which includes classes, methods and properties for communication with PTS controller for provision of control over dispensers and ATG systems and configuration of PTS controller

- open-source utility for testing and indication of all operations provided by the PTS controller, allows to perform all operations with the PTS controller

- Python - API for communication with a PTS controller through a COM-port, documentation and examples of application in source codes

- Visual Basic .NET:

- open source library, which includes classes, methods and properties for communication with PTS controller for provision of control over dispensers and ATG systems and configuration of PTS controller

- open source PTS controller configuration and testing utility

- open-source utility for testing and indication of all operations provided by the PTS controller, allows to perform all operations with the PTS controller

- open source fully-functional application for provision of control over up to 8 pumps and 4 ATG systems by the PTS controller, allows to perform all operations with the PTS controller

- COM-object for PTS controller:

- open-source COM-object (written in Microsoft Visual C++ 6.0 IDE in C++ programming language) with methods and properties for communication with PTS controller for provision of control over dispensers and ATG systems and configuration of PTS controller

- open-source application in Microsoft Visual Basic 6.0 for testing and indication of all operations provided by the PTS controller, allows to perform all operations with the PTS controller

- Description of communication protocol of PTS controller - describes communication parameters, message structure, commands and responses between POS management system and PTS controller, typical flowchart and a diagram of interaction

PTS controller SDK (Software Development Kit)

PTS controller SDK (Software Development Kit) is intended for developers of POS management software for petrol stations that want to control fuel dispensers and ATG systems from their software.

PTS controller SDK includes:

Hardware:

- PTS controller over fuel dispensers and ATG systems for petrol stations - 1 pcs

- Interface converter RS-485 / RS-232 - 1 pcs

- Cabling

Software:

- Software simulators of prevalent fuel dispensers

- Software simulators of ATG systems (probes)

- API for developers in various programming languages:

- C and C++

- C#

- COM-object

- Delphi

- Java

- Python

- Visual Basic 6.0

- Visual Basic .NET

- Description of communication protocol with PTS controller

- "All in one" configuration utility for configuration, firmware update, logging and diagnostics of the PTS controller

- PumpDemo - free contracted version of NaftaPOS software for petrol stations

- Useful utilities for debugging of communication with PTS controller

PTS controller SDK is required and designed for software developers for:

- Improve understanding of operating the PTS controller.

- Implement the PTS controller into own developed POS management system or software application for control over fuel dispensers and ATG level measurement systems for petrol stations.

- Debug own software application to correctly provide control over fuel dispensers and probes locally (on the workplace) without need to connect to real fuel dispensers and probes using software simulators of pumps and probes supplied in structure of SDK.

Firmware updates

PTS controller firmware is constantly being improved and new communication protocols are added. New versions of PTS controller firmware are available for download to customers.

Technical support

Support team provides 24 hour help and customer assistance on any questions which may arise with PTS controller. Questions are answered by experienced developers and programmers, who have sufficient knowledge and can assist with any questions regarding software development.

-

Refinery distillation equipment crude oil distillation equipment custom DEG accessories sales support weight material normal

-

Flow Line Plug Valve API 6A High Pressure Plug Valve

-

cameron fls gate valve / API6A plate gate valve / well valve

-

Cameron FC/FLS Gate Valve Repair Kits

-

API Standard Plastic or Steel Thread Protectors for Petroleum Drill Pipe and Casing

-

API 6A FMC figure weco 1502 1003 602 hammer coupling

-

Limited Price Discount Factory Direct Wholesale High Quality Flexible Connector

-

Refining equipment Crude oil equipment customization

-

Protectors with plastic and steel threads

-

Refinery Distillation Equipment Crude Oil Distillation Equipment Custom DEG Parts Sales Support Weight Material Normal

Other Products

-

$1.00 / piece

$1.00 / piece