pva water soluble laundry pods making machine detergent capsules packing machine

-

Supplier: Foshan Polyva Materials Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Polyva Xu -

Price: $260000.00 /set -

Min. Order: 1 set

| Payment Terms: | L/C,T/T,Western Union; | Packing volume: | 10-30g(customized); |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Brand Name: | POLYVA; |

| Voltage: | 380V; | Supply Ability: | 2 Set/Sets per Month; |

| Min Capacity: | 300pcs/min; | Max Capacity: | 600pcs/min; |

| Certification: | CE Certificate; | Place of Origin: | Guangdong China; |

| Power(W): | 12.5KW; | system: | FFS system; |

| Warranty: | 1 Year; | Delivery Detail: | 90 days; |

| package: | carton; | Name: | liquid detergent pods filling Packing Machine; |

| Automatic Grade: | Automatic; | Packaging Detail: | seaworthy wooden case; |

| Condition: | New; | Usage: | Other Forming Machine; |

| Application: | liquid capsule package; | Function: | Forming ,Filling,sealing; |

| Dimension(L*W*H): | 3500*1150*2350mm; | Weight: | 3000KG; |

| keyword: | water-soluble pouches packing machine; | Port: | Guangzhou Huangpu; |

| Forming drum: | 10 lanes * 48 row; |

Polyva rotary drum type high capacity laundry pods making machine

5-30g laundry detergnet capsules

Introduction

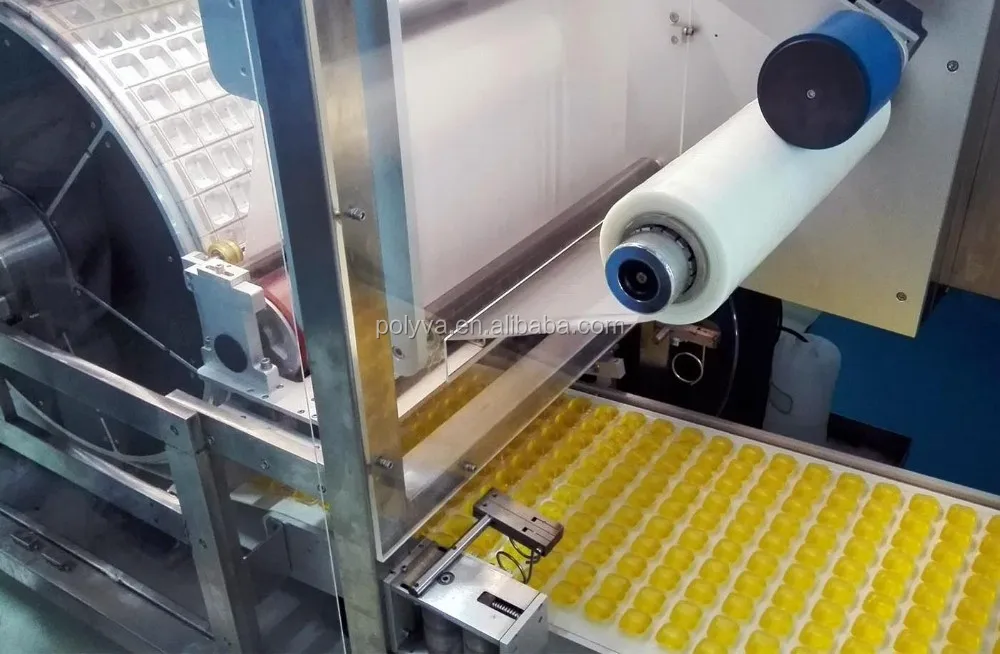

NZB-10 series automatic laundry pods packing machine is a rotary drum-type unit dose non aqueous liquid pods forming, filling, sealing and cutting equipment. It is an automatic high capacity water-sealing packing machine specially designed for high concentrated laundry detergent pods. It has good adaptability of water soluble PVA film and detergent liquid.

1. Rotary drum-type liquid filling, servo motor driving, which ensure precise control of production consistency, production pace flexibility.

2. Plunger pump filling system, accurate dosing. Well corrosion resistance and high reliability filling system.

3. CNC machining mould cavity, which guarantee the uniformity, consistency of the detergent pods shape.

4. Self-designed water cool sealing structure reduces sealing temperature, greatly protect the water solubility of PVA film.

5. Integrated cutting system for finished product, horizontal and vertical cuts along with the roller moving. It keep consistent rate of the drum which provides good production consistency.

6. Adopts PLC control. temperature, pressure, speed and other parameters can be set via the human-computer interface touch screen.

7. Adopts famous brands (Schneider, Mitsubishi…) main electronic components. Long service life.

Parameter Sheet

Min Capacity | 300pcs/min |

Max Capacity | 600pcs/min |

Forming drum | 10 lanes * 48 row |

Packing volume | 10-30g(customized) |

Weight tolerance | ±0.05g |

Dimension | L3500×W1150×H2350mm |

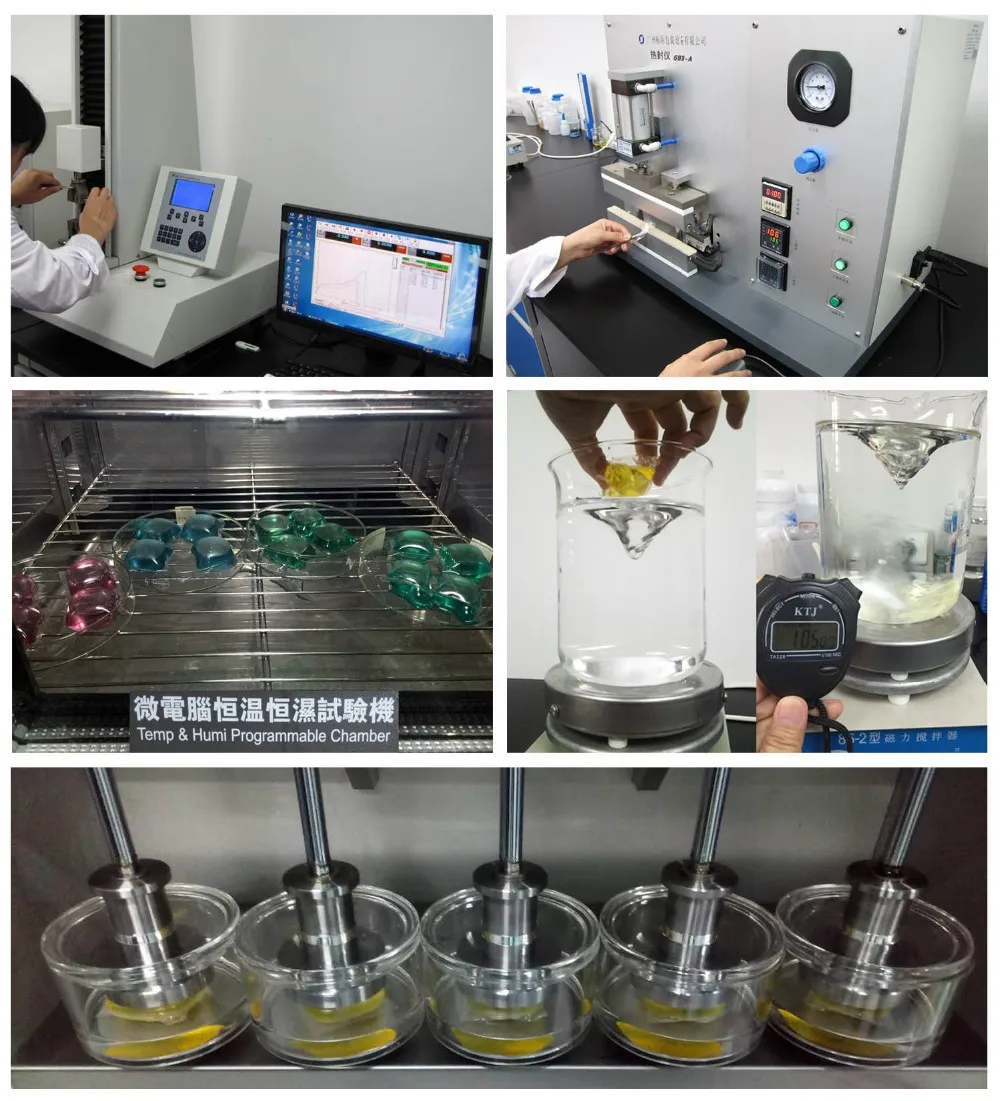

Machine trail and customer training

Patents for film transfer unit, rotary drum forming unit, film clamping, sealing and the whole machine design

L0232 matt finish film

L0832 transparent film

Film & Pods testing

-

Lunch Box Hot Blow Molding Machine

-

Carton cardboard box forming machine carton forming packaging machine

-

High speed automatic partition machine

-

Match Biscuit Roller

-

SW 900 Automatic Grooving Machine

-

Carton Box Making Machine Automatic Corrugated Cardboard Box Flexo Die Cutting Machine/Printing Machine/Carton Slotting Machine

-

Carton Box Case Liner Bag Placing Machine

-

One Piece Cardboard Wrap Box Former

-

One Piece Folder Cardboard Box Forming Machine

-

Poly Bag Inserter Machine for Placing Liner in Carton Case

Other Products

-

$88000.00 / set

$88000.00 / set -

$248000.00 / set

$248000.00 / set -

$230000.00 / set

$230000.00 / set -

$2700.00 / set

$2700.00 / set