metal roofing galvanized aluminum corrugated steel sheet making machine colored steel wall roof panel cold roll forming machine

-

Supplier: Cangzhou Zhongde Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Mr Jie Yang -

Price: $4800.00 /set -

Min. Order: 1 set

| Port: | Tianjin; | Type: | Tile Forming Machine; |

| Brand Name: | roofing corrugated steel; | Tile Type: | Colored Steel; |

| diameter of shaft: | 70/75/80mm; | Payment Terms: | L/C,T/T; |

| Weight: | 6.7tons; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| split thickness: | 18/20/22mm,as your request; | Voltage: | 380v/50hz,3; |

| face fnish of the rollers: | hard chrome coating,2 times polishing; | Certification: | ISO; |

| material of cutter: | cr12 HRC58-60; | Production Capacity: | 13-15meters/min; |

| Supply Ability: | 30 Set/Sets per Month 45 days; | drive of corrugated roof making machine: | by chain; |

| raw material to process: | galvanized strip; | Packaging Detail: | the double layer roof sheet forming machine and PLC and pump are covered with plastic films,the spare parts in carton.; |

| Dimension(L*W*H): | 8.2*1.3*1.2m; | Warranty: | 2 years; |

| Place of Origin: | Hebei China; | Use: | Roof; |

| thickness of raw material: | 0.3-0.7mm,depends on your request; | way of cutting: | hydraulic cutting,machine will stop; |

| material of rollers: | s45c with hrad chrome coating; | Condition: | New; |

metal roofing corrugated steel sheet roll forming machine

Leading manufacturer in North Of China

specialized manufacturer of roll forming machine with 15 years experience

exported to more than 30 countries,such as USA,COLOMBIA,BRAZIL,PERU,JAMACIA,INDONESIA,INDIA,VIETNAM,PHILLIPPINES,BURMA,KENYA,NIGERIA,SOUTH AFRICA,MALAWIS etc.

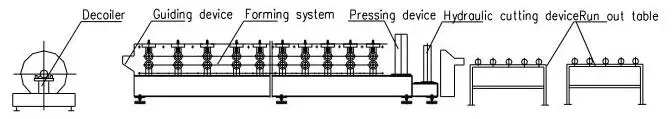

1.Working Flow& Layout

2.Supplying components of complete machine

3.General parameters

Decoiler

1.Features:

Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

2.Power: None

3. Power of the open and closure of segments: Mechanical

4.Power of rotation of segment: Pull by forming system

5.Number of segment: 4

6.Range of segment expansion: 480 ~ 520mm

7.Height of center of the mandrel: 0.65m

8.Feeding speed with push: 0~30m/min

9.Approximate Size: 1.5 m * 1.1m *1.2 m

10.Speed control: By mechanical brake

11.Methods of operation: Manual.

Material Feeder

1.Features: Ensure smooth& precise material feed.

2.Components: steel plate platform, two pitching rollers, position stopping block.

3. The coil is guided in the correct position and passed to the roll forming equipment.

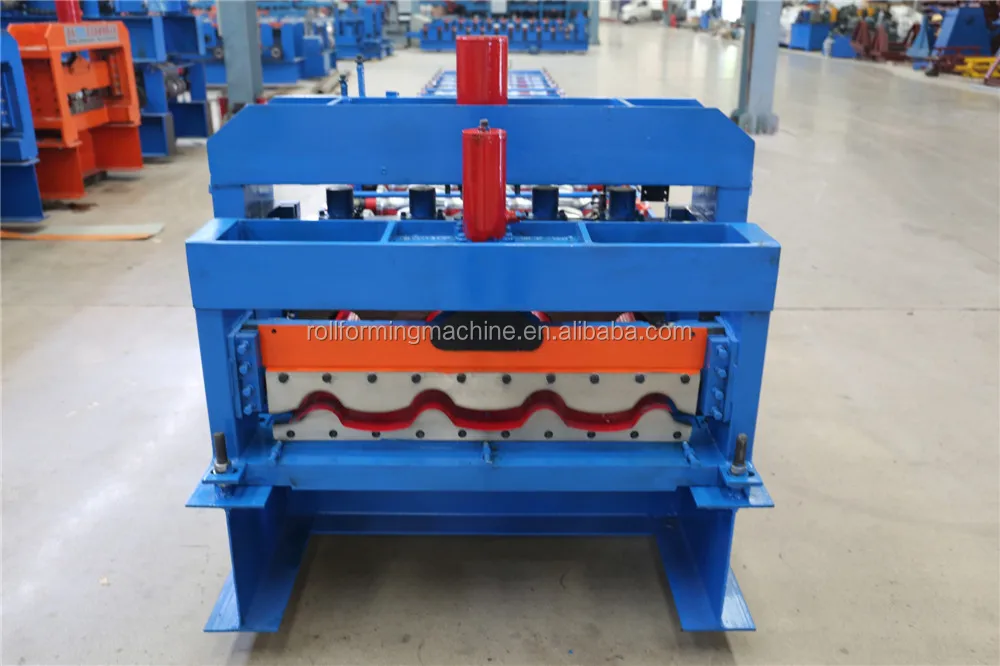

Main forming part

1.Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and coated with hard chrome

2.Shaft:70mm manufactured with 45# high grade steel by CNC machine tools

3. Supporting frame: steel wallboard to guide the forming station bearing basement

4.The finished products will change if using different material and thickness

5.Driving of machine:by one inch chain

Hydraulic cutting

1.Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

2.Power supply: hydraulic station

3.Frame: welding steel frame

4.Stroke switch: non-contact photoelectric switch

5.Cutting before forming: cut the sheet after roll forming to required length

6.Length measuring: automatic length measuring

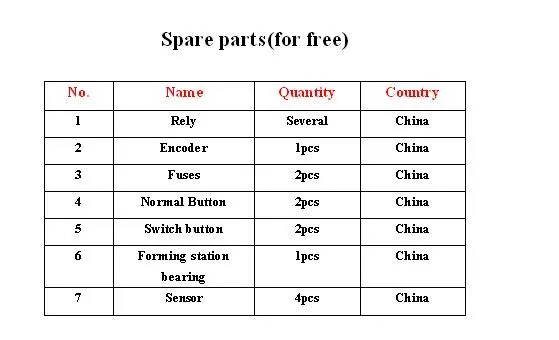

Spare parts for free

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa