Terrazzo brick press

-

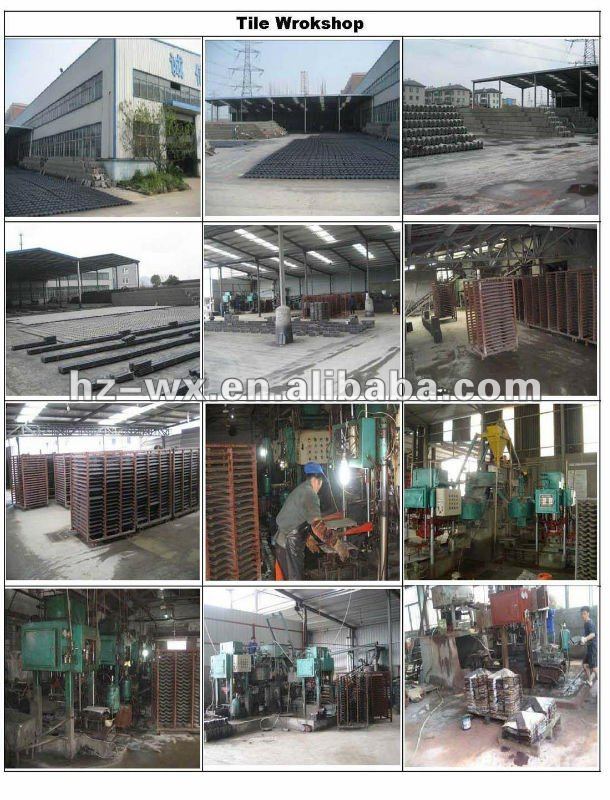

Supplier: Hangzhou Weixing Building Material Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Jesse Wang -

Price: $40000.00 /set -

Min. Order: 1 set

| weight: | 10 tons | Certification: | ISO9001:2008 |

| Applicable industries: | manufacturing plant | port: | Shanghai/Ningbo |

| Health status: | new | Tile Material: | cement, stone, sand |

| Production capacity: | 6-9 pieces/minute | Control System: | PLC (imported brand) |

| Main selling points: | automatic | payment terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| type: | tile forming machine | Warranty: | 1 year |

| After-sales service provided: | Online support, on-site maintenance and repair services | Dimensions (L*W*H): | 3100X1600X2600MM |

| Supply capacity: | 100 terrazzo brick presses per month | Origin: | China |

| brand: | MSI | Package preview: | |

| product name: | Terrazzo brick press | Packaging Details: | Wooden box, 20GP for terrazzo brick press |

| use: | roof | Forming system: | hydraulic |

| Tiles Type: | specific | Voltage: | 380V |

| color: | custom made | Key words: | Terrazzo brick press |

| Programmable Controllers: | Mitsubishi Program Controller |

Terrazzo brick press

1. The new cylindrical tile forming machine has fast forming speed, large output and reliable performance. Using PLC (Mitsubishi technology) automatic control, hydraulic and pneumatic, the production speed can reach 6-9 pieces per minute, with high output and high cost performance.

2. The new type of outer circle forming machine, the bottom surface of the sliding table adopts semicircular guide rail, which is more stable and wear-resistant than square guide rail. The four-cylinder overall positioning of the main oil cylinder not only improves the stability of the equipment, but also prolongs the service life of the mold.

3. The product is formed by filter press, with beautiful structure, various varieties, high density, high strength and accurate size, which can meet the needs of various buildings and is a high-quality product of concrete products.

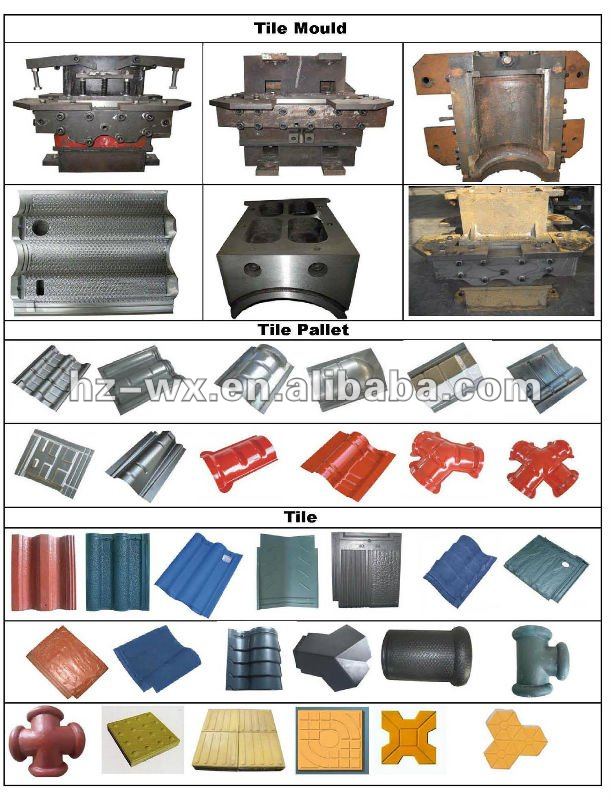

4. One machine is multi-purpose, changing the mould, can produce various types of main tiles and supporting tiles.

5. The self-developed plate film can reduce the cost of cleaning and oiling. This product has applied for a new use patent. Patent No. ZL200820085797·X

Technical Parameters

Technical Parameters | SMY8-128 |

production capacity | 6-9 tablets/min |

Annual production capacity | 900,000 pieces (based on 8 hours) |

factory area | 150 square meters |

Maintenance Area | 60 square meters |

Total installed capacity | 18KW |

manpower quota | 4 people/class |

product specification | 424×337mm2 |

basic plan

No. | Name | quantity | unit |

1 | Forming host | 1 | put |

2 | mixing system | 1 | put |

3 | tile master mold | 1 | put |

4 | tile tray | 2000 | piece |

5 | Round Ridge Tray | 50 | piece |

6 | cornice tray | 30 | piece |

7 | Ridge Making Machine | 1 | put |

8 | Eaves tile making machine | 1 | put |

9 | Floor tile mold | 10 | piece |

10 | TY three round ridge | 1 each | piece |

11 | Slanted Ridge Seal | 1 | piece |

12 | Ridge seal | 1 | piece |

13 | cornice seal | 1 | piece |

14 | Quad mode | 1 | piece |

15 | Plastic diaphragm support plate | 2000 | piece |

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

-

Metal slag tr4 tr5 tr6 aluzinc machines

Other Products

-

$20000.00 / set

$20000.00 / set