CNC Plasma Cutting Machine , Steel Plasma Cutting

-

Supplier: Shandong U-May Cnc Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms Yi Sofia -

Price: $3800.00 /set -

Min. Order: 1 set

| Package Preview: | ; | Control system: | Starfire Control System; |

| Motor and drive: | JMC Stepper motor and drive; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Food & Beverage Shops,Advertising Company,Energy & Mining; |

| Year: | 2019; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Rated Power: | 10.5KW; | Z axis feeding height: | 180mm; |

| Warranty: | 1 YEAR; | Certification: | CE; |

| Motor Type: | Stepper Motor; | Cutting mode: | Plasma Cutting+ Flame Cutting; |

| Model Number: | UT-1325P; | Cutting speed: | 0-10000mm/min; |

| Port: | Qingdao, Shanghai, Guangzhou, Dalian, Lianyungang; | Key Selling Points: | High-accuracy; |

| Voltage: | 110V/220/380V; | Condition: | New; |

| Dimension(L*W*H): | 2200x3300x1500mm; | After-sales Service Provided: | Video technical support,Field maintenance and repair service,Online support,Free spare parts,Field installation, commissioning and training,No after-sales service; |

| Place of Origin: | Shandong China; | Dimensions: | 1300x2500x180; |

| Weight (KG): | 1000; | Product name: | CNC Plasma Cutting Machine , Steel Plasma Cutting; |

| Supply Ability: | 50 Set/Sets per Month; | Working thickness: | 30mm; |

| Brand Name: | UTECH; | Plasma power supply: | 63A; |

| Running speed: | 0-15000mm/min; | Guide rail: | Taiwan HIWIN linear square rail; |

| Packaging Detail: | 1. Packing wooden case is after fumigation treatment. 2. All the spare parts of the machine were covered by some soft materials, mainly avoiding all damages that could happen in the delivery process. 3. The outmost is wooden case with fixed formwork. 4. The bottom of the wooden case has firm iron jack, convenient to handling and transport.; |

CNC Plasma Cutting Machine , Steel Plasma Cutting

Applicable Materials

Aluminum, Copper, Titanium, Nickel, Iron, Galvanized Sheet, White Steel, Titanium Plate, Carbon Steel, Stainless Steel, Alloy Steel, Composite Metal.

Processing area | 1300*2500mm |

Working thickness | 30mm |

Z axis feeding height | 180mm |

Working material | Iron, aluminum, titanium, stainless steel and others |

Running speed | 0-15000mm/min |

Cutting speed | 0-10000mm/min |

Power | 10.5KW |

Input voltage | 380V/220V/110V |

Power supply frequency | 50HZ/60HZ |

Plasma power supply | 63A |

File transfer mode | USB interface |

Working method | Non contact arc |

Driving mode | Gear driving |

Mode of motion | Gantry driving |

X axis motor and drive | JMC Stepper motor and drive |

Overall dimension | 2200*3300mm |

Ventilation system install mouth | Double ventilation mouths |

Weight | 1000kg |

Cooling System | DSP A12S |

Guide rail | Taiwan HIWIN linear square rail |

Plasma generator(power) | Huayuan or Hypertherm plasma(USA) |

Plasma cutting gun | huayuan or Hypertherm plasma cutting gun |

Floating cutting gun mode of motion | Automatic and Pneumatic test |

System | Beijing Start controlling system |

Floating adjustable block | Beijing Start Floating adjustable block |

Body configuration | Steel |

Table configuration | Steel table frame iron lattice |

Material fixed mode | Electrode plate |

processing cutting instruction | EMG, G-code, U00, MMG, NC |

Machine positioning | ±0.15/300mm |

Warranty: 12 months

If the parts are damaged during the warranty period, we will replace the new parts for you free of charge.

1). Before service: We will try to know more about your demands, including the max working size, main processing materials and the thickness, so we will offer you suit machine.

2). Service of training: The English manual and operating video will be sent to customers with the machine together, it will help customer how to operate the machine, it there is any question about the operation, we will have the professional technician to help them how to operate by online, until the customer can use it freely.

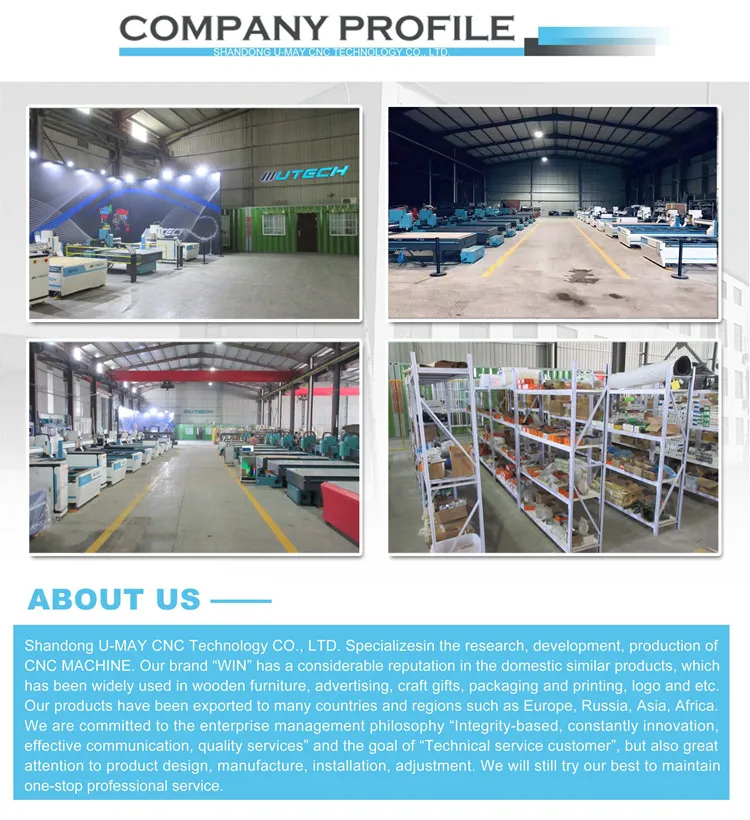

Shandong U-May CNC Technology Co., Ltd. provides one-stop service, including design, installation, training, commissioning, maintenance and consulting. We pursue people oriented management tenet providing staff with a broad development platform, and constantly improving the company evaluation system, incentive mechanism and training system. We always emphasize on research and development. Adhering to the spirit of innovation, we will never stop to develop our own brand and new products. Your satisfaction is always what we pursue. With the expanded market, we sincerely hope to cooperate with customers from all over the world. All parts of the machine can be upgraded or changed. Please tell us your material and size. We will customize the most suitable machine for you.

-

CNC Plasma Cutting Machine Metal Sheet Cutting Machine

-

TNC-3015 Cheap High Precision Desktop CNC Plasma Flame Cutting Machine

-

Customizable 220v Portable Powerful Inverter Air Alasma Cutter Cutting 70 For Stainless Steel Aluminum Carbon Steel Plasma

-

1500*3000 2000*4000mm China metal cutting/cnc plasma table/plasma cutting machine with rotation

-

Mini CNC Plasma Gantry CNC Plasma Cutting Machine Optional Worktable Competitive Price 3000*5000 Auto CAD Offer 300

-

High precision 1630 CNC plasma pipe cutting machine for metal pipe

-

cnc plasma cutting machine portable cnc plasma cutting machine

-

Sell CE Steel Cutting Machine Electric Profile Cutting Machine and J3G3 Cutting Machine

-

1530 Portable CNC Plasma Cutting Machine Metal Gas Cutting Machine

-

High Quality Low Price Portable CNC Plasma Cutting Machine KNCAM Brand CUT 5

Other Products

-

$210.00 / set

$210.00 / set -

$200.00 / set

$200.00 / set