Edible rice making drinking straw machine

-

Supplier: Jinan Keysong Co., Ltd. -

Region: Shandong, China -

Contact: Ms holly huo -

Price: $3000.00 /set -

Min. Order: 1 set

| Supply Ability: | 50 Set/Sets per Month; | Local Service Location: | None; |

| Warranty: | 2 YEARS; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| OEM: | Customer Oriented; | Material: | Stainless Steel; |

| Showroom Location: | None; | Capacity: | 100-250KG/H; |

| Power(W): | 53KW; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Packaging Detail: | Before package, testing machine will be done. Single machine is in nude, spare parts in plywood case, all equipments in container, which are well sealed and strong enough for long-term trip, and suitable for multi-times loading & unloading by forklift.; | Payment Terms: | L/C,D/A,T/T; |

| Product Name: | rice making drinking straw machine; | Delivery: | 15-30 Days; |

| Inverter: | Delta; | Brand Name: | NL; |

| Certification: | CE ISO; | MOTOR: | siemens; |

| Package Preview: | ; | Weight: | 2T; |

| Port: | qingdao; | Condition: | New; |

| Place of Origin: | Shandong China; | Voltage: | 380V 50HZ; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Dimension(L*W*H): | 35001500*2100mm; |

| Control System: | Manual or PLC; |

Brief Information

| Model No | KS-80,100 | Power source | Electric |

| Application | pasta, macaroni, rice straw | Raw material | corn starch, potato starch |

| Motor | Siemens, ABB and others | Warranty | 1 year |

| Material | Stainless steel | Production Capacity | 100-500kg/h |

| Certification | CE, ISO9001 | HS CODE | 843800000 |

| Customized | Yes | Worker needed | 2-4 workers |

| Packing | Wooden case | Origion | Shandong, China |

| Brand name | KS | Voltage | According to customer's local standard |

Product Description

Edible rice making drinking straw machine could produce edible rice straw for drinking instead of plastic straw. to aovid environmental pollution, edible rice straw becomes popular to replace plastic straw. The whole production line includes raw material mixing system, extrusion system, cutting system, cooling system, and drying system. Implement centralized production line fully automatic control, by PLC and touch screen operation, all operations are completed by PLC control of machinery and equipment, reduce the labor intensity of workers and the number of workers, improve the production efficiency.

the automatic pasta straw machine rice straw extruder could also produce Italy macaroni pasta with different shapes like shell, spiral, square tube, circle tube, and so on.

Specifications

Raw material Adopting potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

Capacity 100-150kg/h

Equipments material

Equipments are made of stainless steel and the screw is made of alloy steel and special craft, which guarantee the using time longer.

Flow chart

Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Packing system

Equipments list

Mixer, Screw conveyor, Single screw extruder, Cutter, Cooling machine, Hot air dryer, Automatic fryer, Flavoring line

1.Mixer

function: Mix machine is used to mix raw materials, auxiliary materials and water or other materials of the machine, the speed is moderate, mixed evenly.

features:1.The contact part of the product material is made of stainless steel material.

2. Discharge holes are open new processing design, good sealing, avoid leakage of

material.

2.Screw hoister:

function: Using the mix mix machine screw mechanism of raw materials to the host in the feeder.

3.Single screw extruder

features:1.Use of advanced frequency control skills, work stable and less power consumption.

2.Screw by alloy steel, has a longer service life.

3.Automatic heating control system, easy to work and more accurate parameters.

4.Device configuration water cycle temperature control system.

5.Feeding motor, host equipment, rotary cutting machine adopts frequency control of motor speed.

6.Configure a small single rod extrusion machine, the realization of secondary cure, product curing effect is good.

4. Pulling & cutting

features:1.Cutting knife is used to cut rectangular pipe, pipe.

2.Traction cutting machine has two parts: to cut off the system and transmission system.

3.Equipment operation is simple, the use of frequency control.

4.Commonly used in long, long tube shape small food, such as salad, French fries, pipe, circle half swelling or not puffed food.

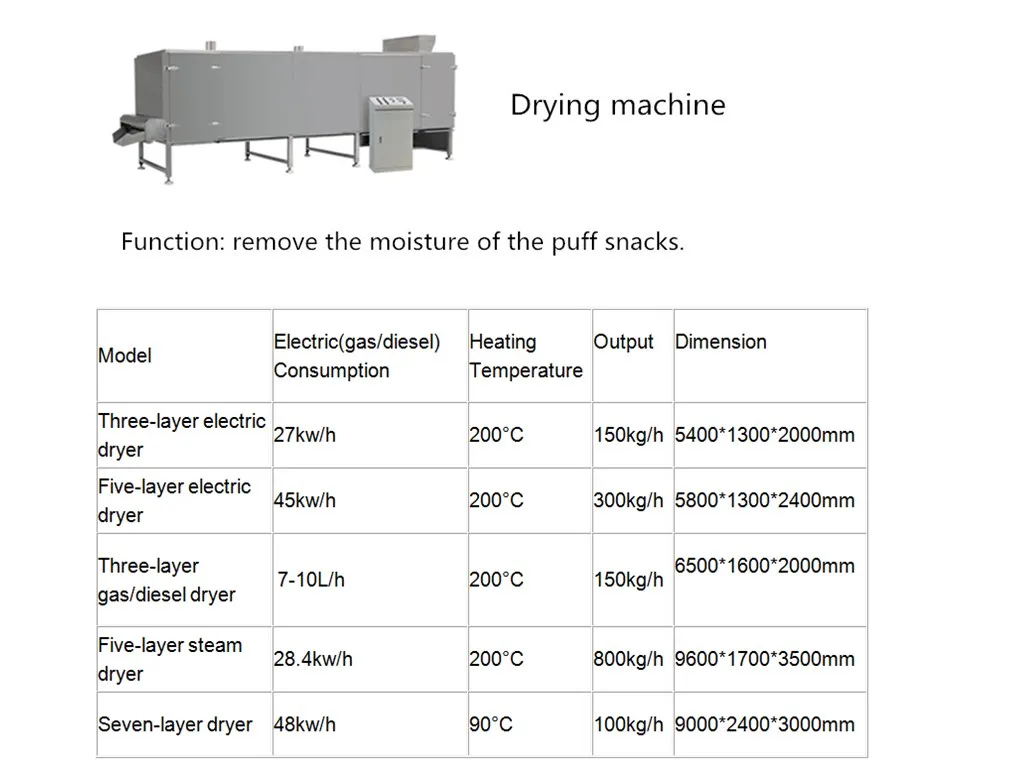

5. Dryer(could be electric, diesel oil, gas and steam)

function:

It can be used to bake dry food. The oven can bake a variety of inflating food, pet food, use/TSP food, peanut, nuts, chew nut and so on.

features:

1.The oven has compact structure, small occupies area, large dry, small area, slight heat radiation, high thermal efficiency.

2.Belt and use stainless steel heat preservation, suitable for food industry.

3.Can control the running speed of the oven belt network(frequency).

4.Temperature can control the arbitrary and design according to the need.

5.Heating pipe heating way, raise and lower the temperature quickly, thermal intertia small, high thermal efficiency.

6.Speed of net belt with accurate temperature control device.

7.Double roller chain and chain drive make stable and smooth running.

8.At the bottom of the sliding plate dryer is easy to clean.

9.Fit for their extrusion snacks, nutritional powder, bread crumbs, pet food, nutrition, rice, dried fruit, soybean protein, etc.

Technical Parameters

| Model | KS-80 | KS-100 |

| Installed Power | 70KW | 100KW |

| Power Consumption | 50KW | 70KW |

| Max. Output | 80-100kg/h | 100-150kg/h |

| Dimension | 29000*2000*2200mm | 27000*2000*2200mm |

Keysong Company Info:

Keysong was founded in 2013. Specializing in producing food machines for more than 6 years.

Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

Puffed food equipment: food extruder, twin screw extruder, single screw extruder, breakfast cereals/corn flakes production line, fried and baked snacks production line, pet food production line, fish feed production line, textures soya protein production line, modified starch production line, bread crumb production line, laboratory twin screw extruder, nutritional rice production line, etc.

Vegetable washing and drying machinery: brush washing peeler, fully automatic roller cleaning and peeling machine, vegetable and fruit slicer, blanching and pasteurization equipment, vegetable and fruit drying machine, tunnel type dryer.

FAQ

1.Are you a factory or trading company?

We are the manufacturer and we have morethan10 years factory experience.As only the machine made by ourself,quality can be trusted,and most important thing is we can do better service after sales.we know how to fix the problem in each parts easily, so welcome to visit to our factory

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

3. How should I pay for my order? what is the procession of this purchase?

You can do 30% prepayment at first, then we will start to make production.

when the machine is ready , we will take pictures to you, and then you can do the balance.

after we got your payment. We will send the machine to you.

4. How about your service after sales? Can your engineer speak fluent English?

We offer the service from you received the machine, including installation of the machine,

how to use machine? how to let machine work? usually we will teach you how to do by email or by Skype. Our engineer has many years of experience for CNC machine service. he can speak very good English, so he can solve the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by client.

Service

Our engineer would go to buyer's place to install the machine, when the equipment arrived at buyer's place.

1). At least 1 year from the date of completion of the commissioning.

2). Free consultation service before, during, and after sales;

3). Free project planning and design services;

4). Free debugging of equipment until everything is functional;

5). Free management of equipments long distance shipping;

6). Free training of equipment maintenance and operating personally;

7). Free new production techniques and formulas;

8). Provide 1 year complete warranty and life-time maintenance service;

Please feel free to contact with us:

Jinan Keysong Machinery Co., Ltd.

NICOLE ZHANG

MOBILE:+86-13075385414

WHATSAPP: +86-15562673064

-

Plastic straw automatic flexible plastic straw bending machine

-

Beverage Paper Straw Machine Fully Automatic Paper Straw Making Machine

-

High speed automatic paper straw machine

-

High Speed Straw Production Machine Paper Straw Forming Machine

-

ORME fully automatic plastic edible beverage straw machine flexible straw production line

-

Small diameter automatic paper straw making machine milk tea straw bending machine

-

10000 pcs/h automotive China supplier edible biodegradable straw production line manufacturing machinery

-

Used paper straw making machine 6 knives, used paper straw 6 knives machine, paper straw machine

-

Fuyuan Factory Paper Straw Making Machine Full Servo Motor Paper Straw Making Machine

-

Automatic Plastic Straw Extruder/Making Machine Offered by KUNCHI