10% discount trapezoidal metal roof sheet roll forming machine in stock

-

Supplier: Botou Kexinda Roll Forming Machine Co., Ltd. -

Region: Hebei, China -

Contact: Ms Ping Li -

Price: $7000.00 /set -

Min. Order: 1 set

| Name: | Roofing Sheet Roll Forming Machine; | Dimension(L*W*H): | 6..3*1.3*1m; |

| Certification: | CE&ISO; | Supply Ability: | 50 Set/Sets per Month roof panel roll forming machine; |

| control system: | PLC control system; | Brand Name: | kexinda; |

| Voltage: | 380v or any; | Material of cutting blade: | Cr12 Heat Treatment; |

| tile type: | steel sheet roll forming machine; | Delivery Detail: | 40 days after we receive the deposit; |

| Type: | Tile Forming Machine; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Condition: | New; | Place of Origin: | Hebei China (Mainland); |

| Cutting type: | Hydraulic Cutting; | Payment Terms: | L/C,T/T; |

| type: | cold roll forming machine; | Power(W): | 3kw; |

| Packaging Detail: | main Roof roll forming machine is nude in the container; | The shaft: | 82mm; |

| Model Number: | 1000; | Tile Type: | Colored Steel; |

| Weight: | 6T roof sheet roll forming machine; | Use: | Roof; |

| Port: | tianjin xingang; | Function: | Roof Panel; |

| Warranty: | 12months; | Main frame: | 350H Steel; |

| Production Capacity: | 8-12m/min; | Roller material: | 45# Forged Steel; |

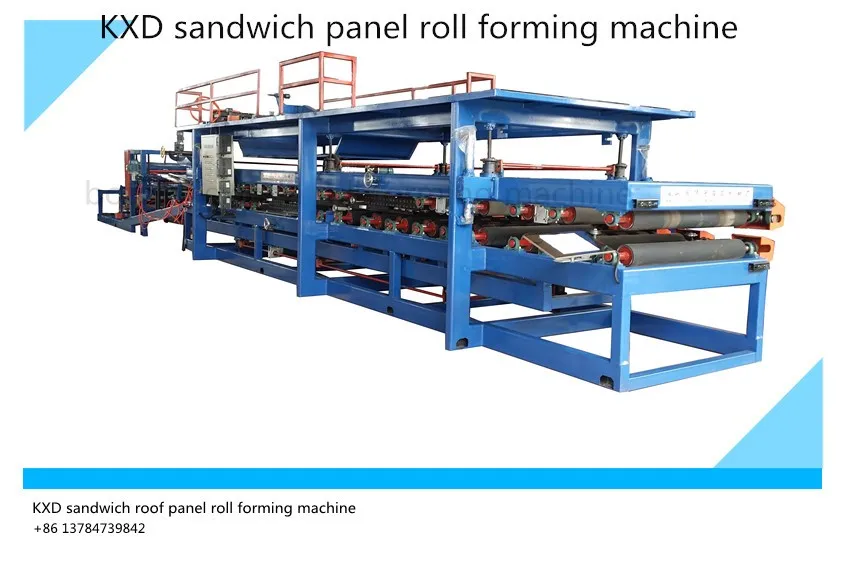

KXD Roof panel Roll Forming Machine

1. Roof Panel Roll Forming Machine Photos

2. Processing flow diagram of our roof roll forming machine

Manual decoiler→→ Feeding material into machine →Roll forming machine →Measure length→Hydraulic cutting →Finished Products

3. Technical parameters about roof roll forming machine

ROOF PANEL ROLL FORMING MACHINE | ||

1 | Suitable to process | Color steel |

2 | Width of the raw material | 1200 |

3 | Output width | 1000 |

4 | Rollers | 16 rows |

5 | Power | 4kw+4kw |

6 | Thickness of the plate | 0.3-0.8mm |

7 | Productivity | 12-15m/min or 25-35m/min by hydraulic motor |

8 | Diameter of the roller | 72mm |

9 | Weight | About 4 T |

10 | Voltage | 380V 50Hz 3phase |

11 | Received table | 4 meters |

12 | Raw material of the cutter | Cr12 |

13 | Raw material of the roller | Bearing steel |

4. Why choose us - KXD roof sheet roll forming machine

We are Professional

We have more than 20 years manufacturing experience in cold roll forming machinery.

Our Business Ability

Till now, we have exported to more than 70 countries and areas. The main market is South America, Africa, Middle East, Eastern Europe, Southeast Asia. We also take part in different exhibitions allover the world.

All kinds of certificate

We get different kinds of certificate, like CE, ISO, SONCAP as so on, based on our strong quality, we are sure than we can meet your certificate requires.

6. After-sales Service

We can provide oversea after sales. Our engineers are availble to go to customer country to install the machine and training for u.

7.FAQ

1. You are the manuafacturer or trading company ?

A: We are the professional manufacturer , and we have more than 20 years professional experiece in the field of roll forming machine.

2. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan

for the machine.

3. How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

4.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

8. more products you may need

9. contact infomation

| Monica Wang | |

| skype | me-monica | |

| Phone | +86 13784739842 +86 15831767931 | |

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa