PP Spunbond Non-woven Fabric Machine, Nonwoven Fabric Making Machine, Automatically Non Woven Production Line

-

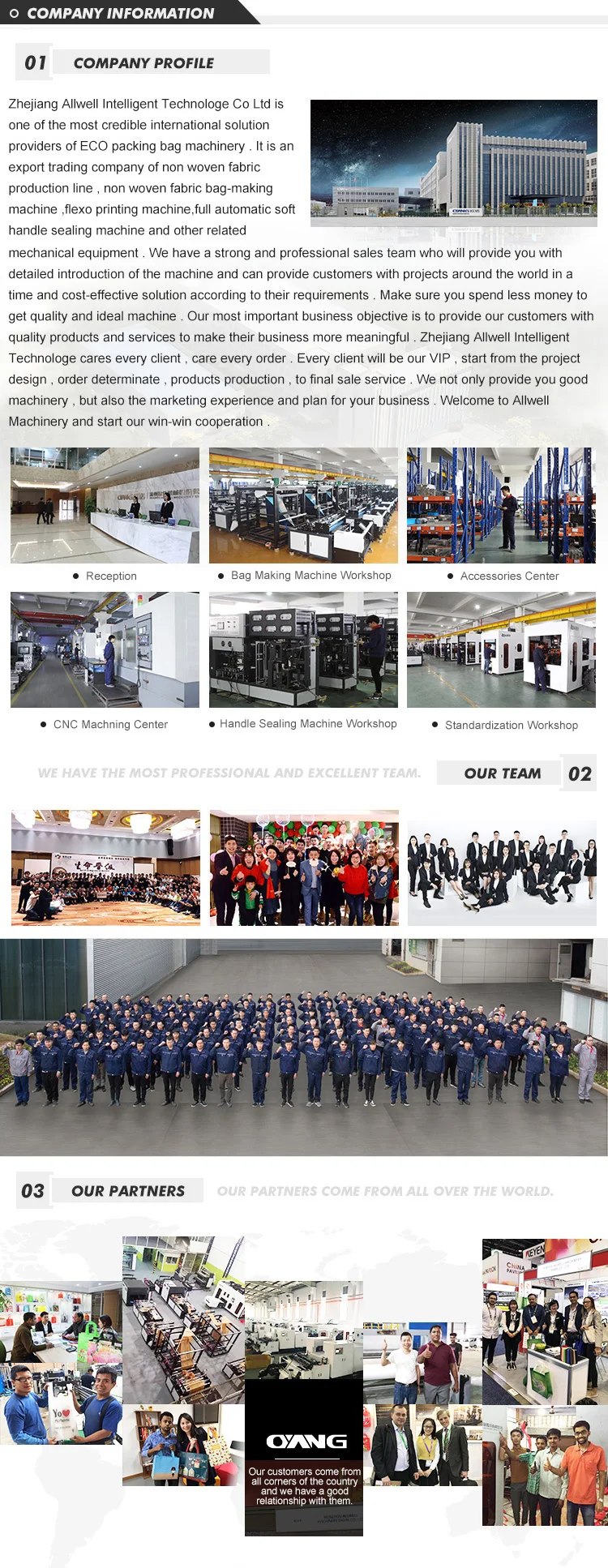

Supplier: Zhejiang Allwell Intelligent Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Sara Yang -

Price: $285000.00 /set -

Min. Order: 1 set

| Dimension(L*W*H): | 11*10*15M; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Place of Origin: | Zhejiang China; | Electricity: | 1300KW for full line; |

| Supply Ability: | 30 Set/Sets per Month; | Key Selling Points: | Automatic; |

| Product width: | 1600mm (final nonwoven product); | Brand Name: | Allwell; |

| Product gram: | 14-120 g/m2; | Packaging Detail: | Wooden case.duly package for sea shipment containerization 1.6S ----4x40'HQ + 1x20'GP; 1.6SS---9x40'HQ + 1x20'GP; 2.4S-----5x40'HQ; 2.4SS---10x40'HQ; 3.2S-----7x40'HQ; 3.2SS---15x40'HQ..; |

| Applicable Industries: | Manufacturing Plant; | molecule uniformity degree: | >95%; |

| Melting index: | 20-40(g/m2 ); | Port: | NinBo; |

| Power: | 250-415KW; | Local Service Location: | None; |

| Warranty: | 1 Year; | Certification: | CE; |

| gray proportion: | <200PPM; | melting point: | 165 (0C); |

| Production capacity: | 9T/Day (Based on fabric≥40g/m2 ); | Condition: | New; |

| Automatic Grade: | Automatic; | Weight: | 4000KG; |

| Payment Terms: | L/C,D/P,T/T,Western Union; | Final product: | Product PP spunbonded nonwovens; |

| Showroom Location: | None; | Voltage: | 220V/380V; |

AW-SS Model High speed non - woven fabric production line | |||

SS(Prodnct width) | 1600mm | 2400mm | 3200mm |

Equipment | 29x13x10m | 30x14x10m | 32x15x10m |

Speed | 350m/min | 350m/min | 30m/min |

Gram Weighht | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

Yield(Products according to 20g/M2) | 9-10T/Days | 13-14T/Days | 18-19T/Days |

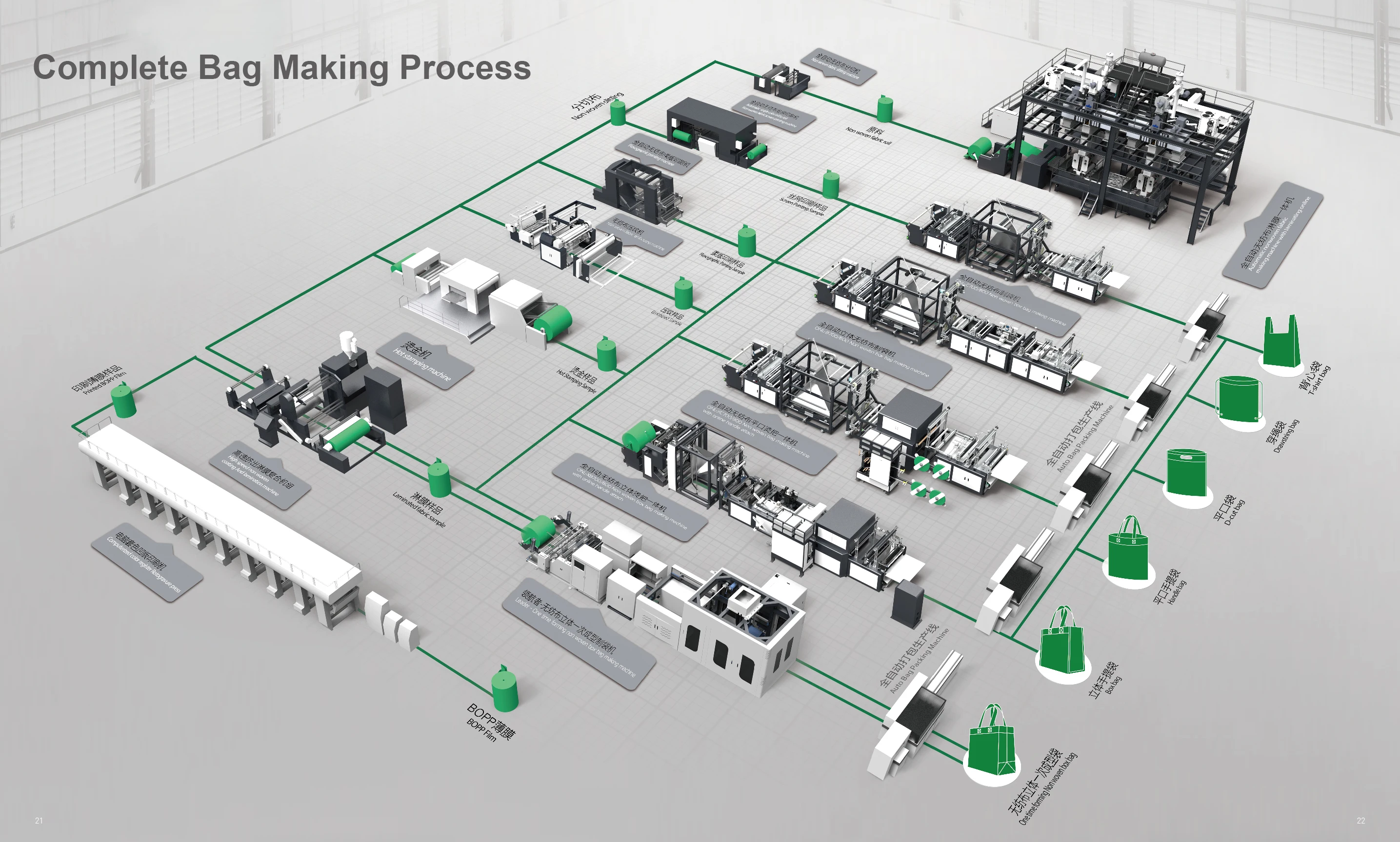

This machine is suitable for PP spunbond non woven fabric making. It used PP chips as raw materials input, undergoes

the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding and cutting as

per requirements and then packed for storage and delivery.

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

NONWOVENS APPLICATIONS

Allwell Nonwoven lines are designed and manufactured in accordance with individual customer requirements. Their possible

area of application is correspondingly wide. Such as :

PACKAG - Shopping bag, Rice Packaging, Clothes packaging, etc.

HYGIENE - Baby and adult diapers, Female hygiene, etc.

MEDICAL - Surgeon's masks, Disposable garments, etc.

FURNITURE - Beds Cover, Seatings Cover, etc.

TECHNICAL - Geotextiles, Agriculture, etc.

FILTRATION - Air, Gas, Liquids, etc.

Q1. How long will your engineer reach our factory?

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 80USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.weour after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

-

Disposable Massage Bed Cover Bed Sheet Making Machine Cover Making Machine Non Woven Fabric Perforating Machine

-

Germany Free Sample Nonwoven Fabric Making Machine Nonwoven Fabric Making Machine Nonwoven Fabric Machine

-

Disposable Medical Garment Non-Woven Making Machine For A Long Sleeve Doctor's Apron

-

Felt Mattress Production Line High Quality Waste Recycling Machine

-

Hot-bonded polyester fiber quilt/quilt making machine/hot-bonded cotton production line

-

Tongda TDL-GI Textile Machinery Non-woven Non-glue Cotton Production Line Felt Polyester Fiber Non-woven Equipment

-

Polyester staple fiber making machine

-

Polyester fiber opening machine Wool fiber carding machine

-

Electric 3D-15D Polyester Cotton Opener Pillow Sofa Pillow Cushion Filling Machine Textile Fiber Opener

-

Polyester Opening Carding Pillow Filling Machine Waste Cotton Fiber Opening Machine Seat Cushion Plush Filling Recycling Machine

Other Products

-

$38000.00 / set

$38000.00 / set -

$12000.00 / set

$12000.00 / set -

$6000.00 / set

$6000.00 / set -

$18000.00 / set

$18000.00 / set -

$18000.00 / set

$18000.00 / set -

$10000.00 / set

$10000.00 / set -

$6500.00 / set

$6500.00 / set -

$25000.00 / set

$25000.00 / set -

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set -

$12000.00 / set

$12000.00 / set