ONL-G700 Nonwoven Bag Sealing Machine, Non Woven Soft Handle Sealing Machine

-

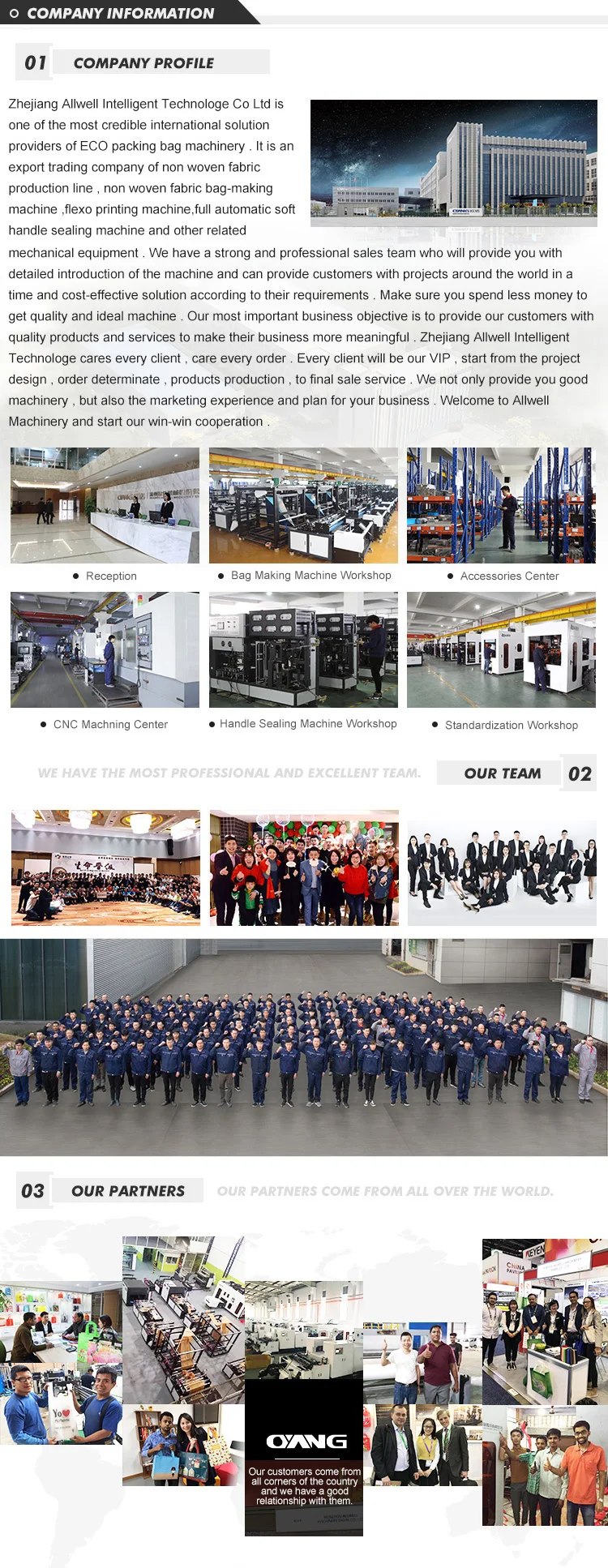

Supplier: Zhejiang Allwell Intelligent Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Sara Yang -

Price: $6000.00 /set -

Min. Order: 1 set

| Video outgoing-inspection: | Provided; | Voltage: | AC220V; |

| Applicable Industries: | Manufacturing Plant; | Application: | Commodity,non woven fabric; |

| Max Speed: | OTHER; | Core Components: | PLC,Motor; |

| Key Selling Points: | Easy to Operate; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Loop handle length: | 370-600mm; | Type: | SEALING MACHINE; |

| Brand Name: | Allwell; | Certification: | CE; |

| Dimension(L*W*H): | 1650*800*1300mm; | Production speed: | 10-20pcs/min; |

| Packaging Type: | Bags,Shopping Bag; | Packaging Material: | wood; |

| Place of Origin: | Zhejiang China; | Machinery Test Report: | Not Available; |

| Marketing Type: | New Product 2020; | Driven Type: | Electric; |

| Local Service Location: | None; | touch screen/PLC: | Taiwan; |

| Loop handle thickness: | 60-100g; | Color: | Black; |

| Automatic Grade: | Automatic; | Payment Terms: | L/C,T/T; |

| Export Markets: | Global; | Warranty: | One Year,1 Year; |

| Warranty of core components: | 1 Year; | Port: | NingBo; |

| Packaging Detail: | FQCH-HC450X2 sale eco non woven bag machine with Film wrapped and then exporting standard wooden case, 8 machines can be loaded in a 40 ft container, one year guarantee time, whole life technician support, a set of tools, a box of vulnerable parts, English operation manual.; | Weight: | 800kg; |

| Showroom Location: | None; | Supply Ability: | 30 Set/Sets per Month; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts; | Machine color: | Blback frame white cover; |

| Condition: | New; |

|

Type

|

ONL-G700

|

|

Bag Width

|

370-600mm

|

|

Thickness

|

60-100g

|

|

Power Supply

|

AC 220V

|

|

Speed

|

10-20pcs/min

|

|

Machine Dimension

|

1650*800*1300mm

|

|

Properties And Characteristics

|

This machine uses a unique structure,abandoning the rotating cylinder, control center for the Panasonic PLC,feeding Stepper motors,precision delivery,complete set with the parameters of man-machine interface, more intuitive and easy,especially to shaping device. |

Q1. How long will your engineer reach our factory?

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 80USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.weour after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

-

HZPK F200 Handheld Plastic Glass Bottle Induction Sealing Machine Manual Aluminum Foil Sealing Machine

-

Low price 60mm wholesale electric cup sealing machine small thickened water milk tea jam manual cup sealing machine

-

Manual beer cap sealing machine bottle cap screwing machine

-

High Quality Mini Cup Sealer Sealer 98mm 95mm 90mm 88mm 80mm 78mm 75mm 70mm 60mm 120mm 98 95 90 88 75 73 mm

-

Three caliber plastic cup manual sealing machine WY-802D-12

-

500ml 16 oz 20 oz 24 oz 32 oz 16 20 24 32 oz cup low price hand-held hand press manual cup sealer sealing machine commercial

-

300mm Portable Manual Sealer Plastic Impulse Thermal Bag Sealer With Packaging CE FCC Approved (ABS)

-

FR-900 Aluminum Foil Plastic Bag Automatic Continuous Plastic Bag Heat Sealer Sealing Machine

-

Portable Thermoplastic Bag Sealer Automatic Continuous Sealing Shrink Sleeve Machine Max Steel Key

-

Kitchen Accessories Packaging Sealer Bag Thermoplastic Food Bag Sealer Portable Sealer Packaging Mini Thermal Bag Sealer

Other Products

-

$38000.00 / set

$38000.00 / set -

$12000.00 / set

$12000.00 / set -

$18000.00 / set

$18000.00 / set -

$18000.00 / set

$18000.00 / set -

$10000.00 / set

$10000.00 / set -

$6500.00 / set

$6500.00 / set -

$25000.00 / set

$25000.00 / set -

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set

Leather Patch Nonwoven Aluminium Foil Fabric Textile Embossing Machine, Embossing Machine for Fabric$25000.00 / set -

$12000.00 / set

$12000.00 / set -

$285000.00 / set

$285000.00 / set