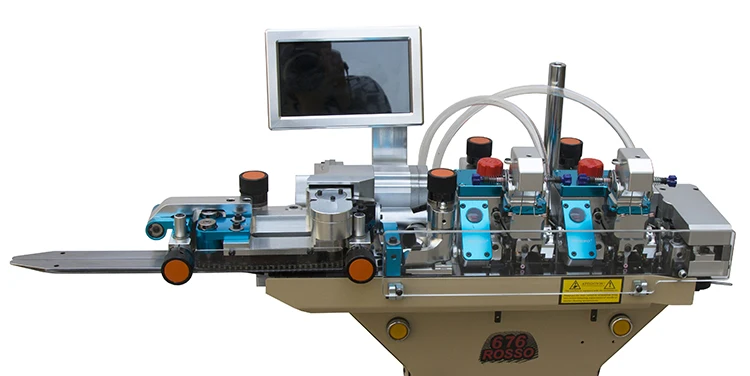

ROSSO 676 sock toe sewing machine linking machine for socks

-

Supplier: Zhejiang Rosso Equipment Manufacturing Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Rosso ZJ -

Price: $1100.00 /set -

Min. Order: 1 set

| Packaging Detail: | sock toe sewing machine linking machine Standard wooden Case; | Certification: | CE Certificate; |

| Port: | NingBo Shanghai Guangzhou; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| sock toe sewing machine linking machine: | sock toe sewing machine linking machine; | Condition: | New; |

| Place of Origin: | Zhejiang China; | Brand Name: | ROSSO; |

| Package Preview: | ; | Type: | Socks linking Machine; |

| Dimension(L*W*H): | 98*48*132cm; | Production Capacity: | 1000 pairs/h; |

| Supply Ability: | 500 Set/Sets per Month; | Power: | 1070W; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Warranty: | 1 Year; |

| Voltage: | 220V; | Weight: | 119KGS; |

sock toe sewing machine linking machine

| ROSSO-SOCKS LINKING MACHINE | |

| Voltage | 220V(special country voltage 110V can be customized ) |

| Power | 1070W (fan370W,machine700W) |

| Frequency | 50-60Hz |

| Gross weight | 119KG |

Package size | 98*48*125CM |

| Max speed | 4500RPM |

| Click to get latest price now! | |

Functional characteristics

1. Automatically lubricating nose device makes a longer performance life and a better working environment with low-noise.

2. Adopting automatically cutting device,the sutures will be cutting unified length.

3. Turnover yarn feeding device makes the yarn cleaning conveniently.Inner automatic hoisting device is for conveying purpose,assure the sock’s flatness.

4. An optical fiber inductive time lapse function as yarn feeding makes it possible to set delay time according to the running speed,which reduces the waste of sutures substantially when sewing.

5. Adopting dual channel nose device,makes the sock sewed with fine flat seams.

6. Adjusting the sewing density of socks is available with a renewal gear.

7. Point-contact touch screen computer control system makes it easy to handle.

8. There is an automatic hoisting device between the first nose and the second one,act as anti-dropping apparatus when one-sided of socks suddenly fall off.This comes to a better flatness and sewing quality,close to handsewer’s job.

9. Maximum output can reach 1000pairs an hour.

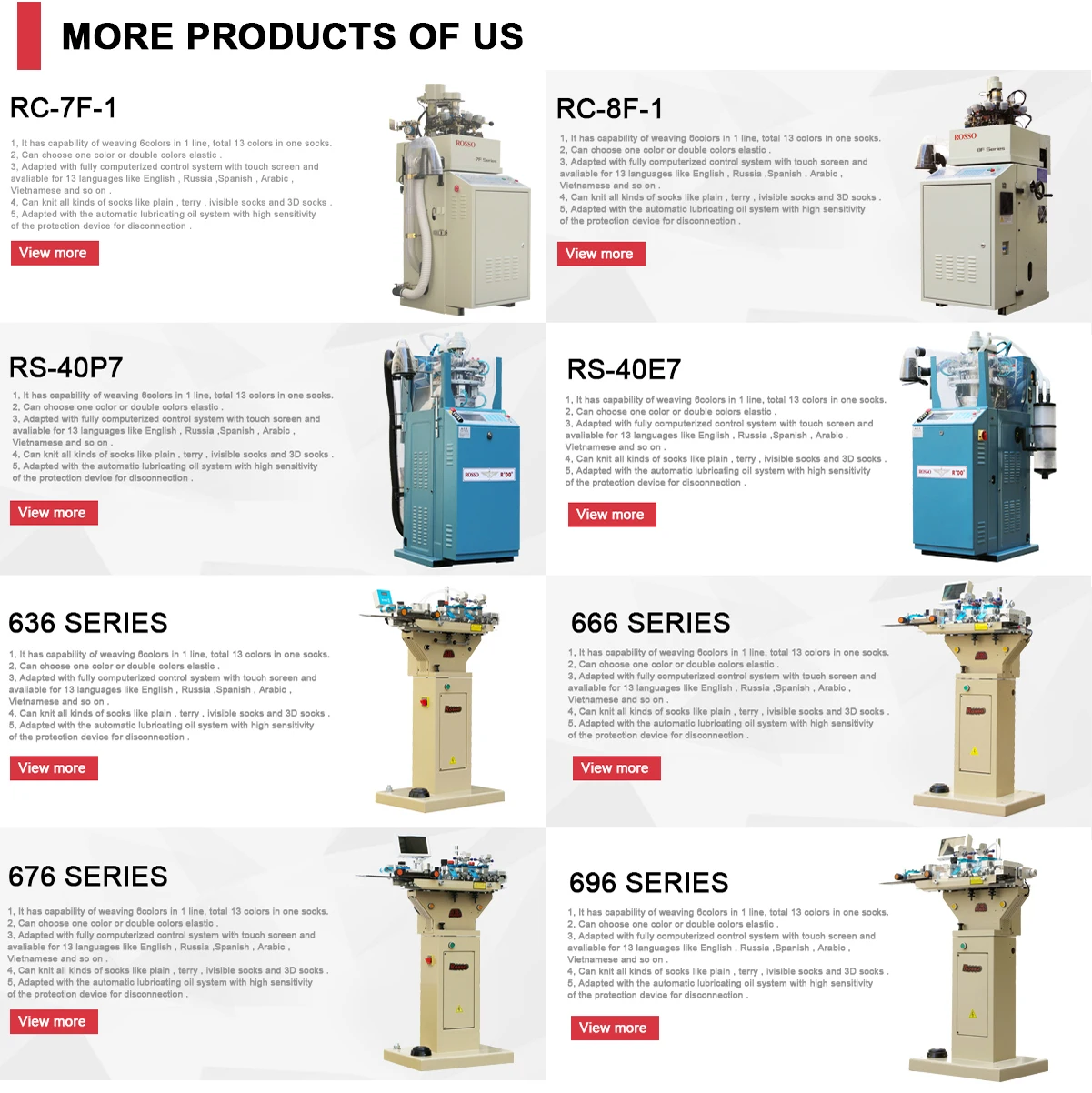

| Different of our machine | |||

| MODLE | Motor | Advantage | Disadvantage |

| 636 | 1 set | Difficult to link perfect. | |

| 676 | 3 set | After linking, the stitch is distinctly. | Socks with different stitches need different gears. |

| 666 | 6 set | Can adjust the density on control computer,socks can stretch out and draw back,well-adapted. | Bad distinct,the motor has inertia ,start and stop can’t fall in the same place. |

| 696 | 5 set | Two needles are distinct,needle stitch is distinct,four wires.Can adjust the density on control computer,socks can stretch out and draw back,well-adapted. | |

ROSSO Company Established in 2002 year, our company is a professional manufacturer and exporter of Sock sewing machines, integrating design, development and production. We are located in Beautiful XiShiGuLi of ZhuJi Shaoxing, Zhejiang, with convenient transportation access . All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.We have over one hundred employees and an annual sales figure that exceeds USD$5 million.We are specialized in manufacturing socks sewing machine about ten years and we have about twenty engineer to develop our machine. So we will produce the socks machine in this year.Our Machine are exported to many countries and regions. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. We have the Q&C department to control the quality and have a very good after-sevice group to sevice. So you don't worry about the quality and sevice.As a result of our high quality products and outstanding customer services, we have gained a global sales network reaching Brazil, Turkey, India, Bangladesh, Vietnam, Pakistan and so on.If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

-

Wanghu Sports 3.75 Inch Terry Socks Making Machine Kids Socks Machine

-

Zhengbao Automatic Round Sock Machine Price Sock Knitting Machinery For Making Socks

-

ROSSO-7F cotton socks knitting machine price is same as lonati machine

-

WLT-6F828 WEKNIT SOCKS MAKING MACHINE

-

HN Low Price Fully Automatic Computerized Socks Machine Making Socks

-

Quick Service Sock Making Knitting Machine Sock Knitting Machine

-

SOCKS MACHINES G615 High Quality Tights SANGIACOMO SANTONI Electronic Machine Best Quality Tights Socks Comfortable

-

Fully automatic computer hosiery machine with good quality and excellent price

-

Rosso 636 Straight Socks Automatic Threading Machine Sewing Machine Good Price

-

China Automatic Sock Knitting Machine Price

Other Products

-

$1500.00 / set

$1500.00 / set -

$1000.00 / set

$1000.00 / set -

$1400.00 / set

$1400.00 / set -

$2500.00 / set

$2500.00 / set -

$1500.00 / set

$1500.00 / set -

$1500.00 / set

$1500.00 / set -

$1500.00 / set

$1500.00 / set -

$1400.00 / set

$1400.00 / set