OEM Good Quality Transmission Crown Pinion Gear

-

Supplier: Shanghai Michigan Mechanical Co., Ltd. -

Region: Shanghai, China -

Contact: Ms penny Peng -

Price: $50.00 / >=100 pieces -

Min. Order: 100 pieces

Product details

| Core Components: | Gear; | MOQ: | 100 Piece; |

| Local Service Location: | None; | Processing: | Hobbing; |

| Diameter: | 20-1000 mm; | Tooth Profile: | bevel gear; |

| Port: | Shanghai or Ningbo; | Video outgoing-inspection: | Provided; |

| Outer Diameter: | custom; | Shape: | BEVEL; |

| Sample: | available; | Hardness: | 45~50 HRC; |

| Direction: | LEFT HAND; | Marketing Type: | Hot Product 2019; |

| Pressure Angle: | 20 Degree; | Certificate: | ISO9001:2008; |

| Place of Origin: | China; | After Warranty Service: | Online support; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Farms,Construction works ,Energy & Mining; | Material: | Steel; |

| Supply Ability: | 2000 Piece/Pieces per Month; | Packaging Detail: | Standard export package or custom; |

| Package Preview: | ; | Machinery Test Report: | Provided; |

| Showroom Location: | None; | Warranty of core components: | 1 Year; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Standard or Nonstandard: | Nonstandard; |

| Warranty: | 6 months; | Brand Name: | SMM; |

SMM support and service will accompany you all the way through the whole cycle of product design,production and after-sales. With our packaged professional knowledge and experience, SMM will provide you with fast and premium service guarantee.

Products Description

Specification | ||

Precision grade | ISO grade 5, AGMA grade 13 | |

Pressure angle | 20° | |

Material | SCM415, 15CrMo, 9310,8620 | |

Heat treatment | Carburizing | |

Tooth hardness | 59±2 HRC, 1.2~1.5 mm | |

Surface treatment | light oiled | |

Module | No. of teeth | Direction of spiral | Bore (AH7) | Pitch dia. (C) | Outside Dia. (D) | Face width (J) | Mounting distance (E) | Total length (F) |

2 | 40 | right | 15 | 80 | 81.1 | 14 | 45 | 31.78 |

2 | 20 | left | 12 | 40 | 44.1 | 14 | 55 | 28.16 |

2.5 | 40 | right | 16 | 100 | 101.29 | 17 | 50 | 33.35 |

2.5 | 20 | left | 12 | 50 | 55.12 | 17 | 65 | 31.01 |

3 | 40 | right | 20 | 120 | 121.57 | 20 | 60 | 39.81 |

3 | 20 | left | 16 | 60 | 66.03 | 20 | 80 | 38.9 |

4 | 40 | right | 25 | 160 | 162.06 | 27 | 75 | 48.27 |

4 | 20 | left | 20 | 80 | 88.46 | 27 | 100 | 45.38 |

Thank you for reaching out to us for your custom gear requirements. Our Engineering team will review your request and will be in contact within 24 hours. - SMM TEAM

Company Profile

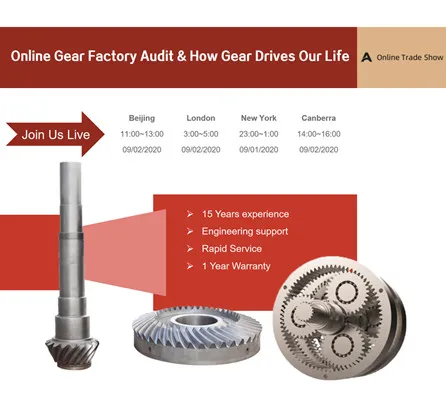

Shanghai Michigan Mechanical Co. Ltd - Concentrate on OEM Transmission Parts for More Than 15 Years.

Mission: Supporting the Further Success of Clients and Partners with Mechanical Solution & Premium Service.

Core Value: Customer First, Integrity, Never Stop Improving.

Mission: Supporting the Further Success of Clients and Partners with Mechanical Solution & Premium Service.

Core Value: Customer First, Integrity, Never Stop Improving.

Related Products

Spiral Bevel Gears for Cement Vertical Mill

375 Spiral Bevel Gears for Oil Drilling Machine

Zero Bevel Gears

Alternate to staight bevel gears

Hypoid Gears

High RPM, high Precision,low noise

High Precision Power Transmission Gears for Machine Tools

Non-orthogonal Spiral Bevel Gears

Precision Gears for UAV

Involute Spline Gears

Gears for Industrial Robot

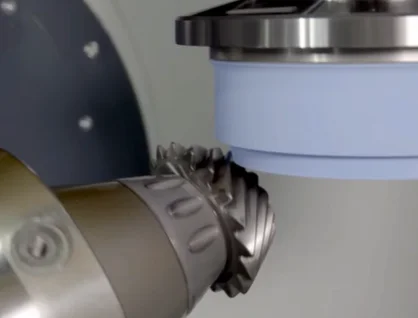

Production Process

Raw Material Rough Cutting Gear Turning Quenching & Tempering

Gear Milling Heat Treatment Gear Grinding Testing

Testing

Gleason 1500GMM Inspection Center

Diameter: 1500

Max Weight:4.5t

Links CNC3906 Inspection Center

Diameter: 600

Automatic Inspection Line

How Do Our Technical And Quality Team Support Our Clients And Partners?

Our english speaking engineers do not simply relay messages. We help both customers and partners to strive for real solutions and we practise Kaizen in every single work.

Quality Warranty : 12 months counting from the delivery of the goods.

Our english speaking engineers do not simply relay messages. We help both customers and partners to strive for real solutions and we practise Kaizen in every single work.

Quality Warranty : 12 months counting from the delivery of the goods.

Product packaging

Inner Package Carton Non-solid Wood Packing Iron box packing

To be packed in new strong case(s)/carton(s), suitable for long distance ocean/air and inland transportation. In addition,we are willing to customize packaging per your request.

Certifications

ISO 9001 certification

ISO/TS 16949 certification

Main Application Fields

Over 15 years accumulating, SMM gears are used in various industries in numerous machines. The main application fields

including,but not limited to machine tools,UAV,Tobacco machinery,new energy automobile,electical tools,cement vertical mill,oil drilling machine.

SMM have been working with some global leading companies more than 10 years.

including,but not limited to machine tools,UAV,Tobacco machinery,new energy automobile,electical tools,cement vertical mill,oil drilling machine.

SMM have been working with some global leading companies more than 10 years.

Why Choose Us

Being proactive, we constantly recognize and strive for opportunities that are beneficial to customers and self-improvement;Action speaks louder than words, we make fast decisions on the needs of customers, suppliers and employees. We are Ready to Support Your Further Success! ——SMM TEAM

VIEW MORE

You may like

-

Mitsubishi Fuso Crown Wheel and Pinion Bevel Gear/Spur Gear MC804120

-

Differential Bevel Gears Crown Bevel and Helical Gears

-

TJ(97-06) Front DANA 30 3.73 short D30373TJ crown and pinion hot sale

-

Free sample tractor differential or truck differential

-

Outboard Spiral Bevel Gear 15HP Pinion 63V-45551-00 arine Engines Yamaha Outboard Gear

-

China Precision CNC Machining Custom Metal Steel Drive Gears and Straight Bevel Gears

-

Low Price OEM Large Metal Spur Gear from drawings

-

33052 GAZ 8*41 bevel gear crown wheel pinion

-

Specializing in the production of bevel gears/sprockets/large diameter gears

-

OEM custom pinion bevel helical gears for sale

Other Products

-

$43.00 / piece

$43.00 / piece -

$16.48 - $24.72 / piece

$16.48 - $24.72 / piece -

$3.00 / piece

$3.00 / piece -

$70.00 - $90.00 / piece

$70.00 - $90.00 / piece -

$3.00 / piece

$3.00 / piece