Full Automatic 100-200b/M Empty PET Plastic Bottle Unscrambler feeding Machine

-

Supplier: Zhangjiagang U Tech Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Eileen Shao -

Price: $11000.00 /set -

Min. Order: 1 set

Product details

| Application: | square round bottles/barrels; | Core Components: | PLC,Engine,Motor,Pressure vessel; |

| Packaging Detail: | wooden case for Automatic Plastic PP PE PET Empty Bottle Unscrambler / Unscrambling Machine; | Supply Ability: | 15 Set/Sets per Month; |

| Automatic Grade: | Automatic; | Type: | Cleaner; |

| Feature: | High Speed; | Local Service Location: | Peru,Pakistan,Mexico,Russia,Thailand,Colombia,Ukraine,Nigeria,Uzbekistan; |

| Warranty: | 2 years; | After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Machinery Test Report: | Provided; | Brand Name: | U Tech; |

| Condition: | New; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory; |

| Certification: | CE; | Showroom Location: | None; |

| Port: | shanghai port; | Function: | Unscramble Bottles; |

| Weight: | 2500; | Capacity: | 6000-15000bph; |

| Usage: | Beverage; | Payment Terms: | L/C,T/T; |

| Suitable object: | PET Plastic bottle; | Warranty of core components: | 2 years; |

| Place of Origin: | Jiangsu China; | Marketing Type: | Hot Product; |

| Model: | LPJ-15000; | Product name: | pet plasitc bottle unscrambler machine; |

| Voltage: | 220V/380V; | Material: | 304 Stainless Steel; |

| Video outgoing-inspection: | Provided; | Bottle volume: | 100ml-2L; |

| Bottle material: | pet pp plasitc pe; | Dimension(L*W*H): | 2290*1210*2520mm; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Key Selling Points: | Easy to Operate; |

| Package Preview: | ; |

Product Introduction

Folding machine (Bottle Unscrambler) is the plastic bottle in a messy situation, scattered and regular bottles will be neatly arranged on the conveyor belt to meet the requirements of high automation. The function of the bottling machine is to arrange the beverage bottles which are stacked in disorder and arrange them in order and direction on the conveyor belt.

Technical Parameters

Model | LPJ-15000 |

Work station | 18 |

capacity | 10000 BPH |

Max capacity | 12000 BPH |

Air pressure | 0.7MPa |

air consumption | 1.5M 3 / min |

bottle | diameter 50 - 96 , bottle height 165 - 310 |

Main power | 1.5KW |

Hoist power | 0.75KW |

Overall dimension | Φ 2300×2340 |

weight | 3400kg |

Machine details

PET bottle unscrambler machine Automatic High Speed Bottle Unscrambler Machine ancillary bottling machine

Performance Characteristics: 1.Frequency converter speed drive fine synchronization, digital display work output, easy to connect with various filling machines. 2. The specially designed bottle drop slot can adapt to the bottle with little difference in size, without the need to replace the bottle drop slot, and improve the production efficiency. 3. lower part of the cylinder body is provided with a maintenance port, which is convenient for maintenance personnel to enter the bottom of the machine. The cabinet is equipped with maintenance lighting, convenient maintenance. 4. is equipped with perfect safety protection measures, when the repair door is opened, the machine can not be started, and the machine can be controlled by manual operator at this time. 5. A bottle-clamping detector is provided 6. the bottle-clamping machine, which can effectively protect the safety of the machine. and equipped with fault indicator light and touch screen to show the cause of the failure. 7. main motor speed regulation through the man-machine interface, can easily set the production speed, and can automatically start and stop according to the air duct or the condition of the bottle on the transport. 8. Full body of SUS304 stainless steel material, simple appearance, beautiful, novel structure,unique, can ensure the bottle clean and pollution-free. |

Control System

S/N | Name | Brand | country |

1 | Main motor | ABB | Switzerland |

2 | Inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- relay | SCHNEIDER | France |

7 | Air-break switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

Related Products

About U TECH

Certifications

FAQ

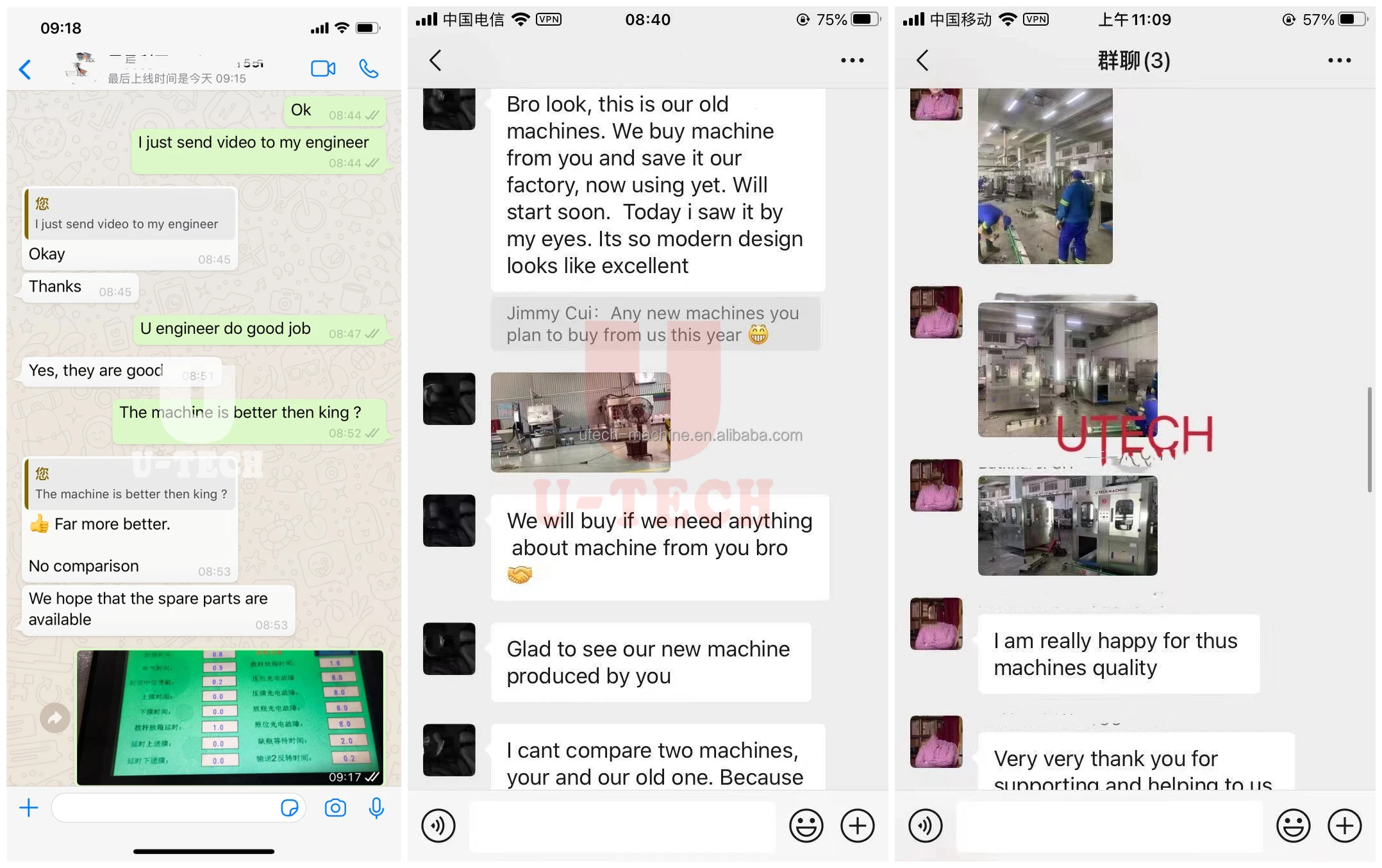

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

VIEW MORE

You may like

-

ZXSMART fully automatic rotating round plastic glass bottle unscrambler, bottle dividing machine, turntable bottle collecting machine

-

Automatic High Quality Speed Feeder Conveyor Bag Counting Inkjet Coding Paging Sticker Labeling System Machine Finishing Bags

-

Stainless steel 304 powder screw conveyor feeder is easy to operate

-

UBL automatic high-speed cardboard label plastic bag paging machine

-

Friction paging machineAutomatic adsorption paging machineAutomatic plastic bag paging machine

-

China Factory Cement Plant Equipment Cement Bag Washing Machine

-

CE Automatic Weighing Filling Machine

-

New Product Multifunctional Candy Packaging Machine Potato Chip Packaging Machine Biscuit Packaging Machine

-

High quality best-selling JBR-15F automatic in-line glass bottle water washing machine

-

YG 9021A Thermal Transfer Printer High Speed Bag Feeder

Other Products

-

$5500.00 / set

$5500.00 / set -

$9000.00 - $15000.00 / set

$9000.00 - $15000.00 / set -

$25000.00 - $30000.00 / set

$25000.00 - $30000.00 / set -

$12000.00 / set

$12000.00 / set

Related Search

empty 330ml plastic bottle pet

pet plastic bottle machinery

waste used pet plastic bottle recycling

pet plastic bottle can

plastic bottle cap sealing machine

full automatic plastic blow molding machine suppliers

full automatic plastic molding machine suppliers

full automatic plastic injection molding equipment

pet plastic granulating machines

full automatic egg incubator wq 1584