Industrial overhead powder coating line conveyor chain

-

Supplier: Chongqing Haodong Technology Co., Ltd. -

Region: Chongqing, China -

Contact: Ms Nancy He -

Price: $16.00 / >=100 meters -

Min. Order: 100 meters

| Port: | FOB China; | Brand Name: | CR; |

| Single-span weight: | 45 kg; | Applicable condition: | General conditions; |

| Material: | steel A3; | Product name: | Industrial overhead powder coating line conveyor chain; |

| Chain's catastrophic pull force: | 5500 kgf; | Chain's Weight: | 4.83kg; |

| Packaging Detail: | Packing in standard export carton, also can packing as your requirement.; | Working temprature: | 300 ℃; |

| Supply Ability: | 50000 Meters per Month; | Tensile Strength: | 3000kgf; |

| Place of Origin: | Chongqing, China; | Chain's allowable pull force: | 3000 kgf; |

| Suspension Spacing: | 150mm; | Usage: | Powder coating line, workshops continual conveying; |

| Type: | Other; | Standard or Nonstandard: | Standard; |

| Payment Terms: | Western Union,T/T,Paypal; | Applicable Industries: | Manufacturing Plant,Construction works ; |

Product Name: Industrial overhead powder coating line conveyor chain

Specification of Industrial overhead powder coating line conveyor chain:

|

MODEL ITEM |

UH-5075-S Standard chain |

UH-5075-HH Heavy-duty chain |

UH-5075-HV Heavy-duty chain |

UH-5075-HA Heavy-duty chain |

|

Suspension Spacing (mm) |

150+(150× N) |

150+(150 × N) |

150+(150 × N) |

150+(150 × N) |

|

Chain's Weight (kg/m) |

4.2 |

4.58 |

4.83 |

5.3 |

|

Single-span Weight (≤kg) |

35 |

40 |

45 |

50 |

|

Chain's Allowed Pull Force (≤kgf) |

3000 |

3000 |

3000 |

3000 |

|

Chain's Catastrophic Pull Force (≥kgf) |

5500 |

5500 |

5500 |

5500 |

|

Working temperature (≤°C) |

250 |

300 |

300 |

400 |

|

Applicable Equipment |

General conditions |

Large bending; High temperature; |

High temperature; Heavy work piece; Frequently lifted; |

High temperature; Heavy work piece; Complicated route; |

|

Material |

16# Medium-carbon steel, Steel A3 |

|||

|

Remark: The above technical data is for our usual hanging type conveyors: UH-5S, UH-5HH, VH-5HA type. We can customize design and manufacture the products based customers particular requirements. |

||||

Other Accessories for Industrial overhead powder coating line conveyor chain:

| Spare parts item | Features | Photo |

|

Up-Down track (Vertical curve track) |

for rising or falling areas. standard diameter is 1.2 meters,180º angle. it can be cut based on any necessary angles of any install conditions.the angle should not be more than 45º angle. the distance between two adjiacent hangers should be considered. |  |

| Check track | There is a hatch which can open the track, through the hatch, worker can dismantle or install, check or maintain the conveying chains. Driving device for each conveying route is usually located between driver and take-up device for easy checking and maintenace. |  |

|

Take-up device (Tensioner) |

Keep the chains in the state of original tension and compensate for the tensile deformation caused by tensile force or telescopic deformaton caused by varied temperature while working. Make sure certain tensile force between driver and take-up device. Install it behind driver about distance 3~6 meters. Better have no up-down track behind take-up device. |

|

| Straight track | for where conveyor chain go straight. it can be cut according to the specific install condition. standard length is 3 meters. |  |

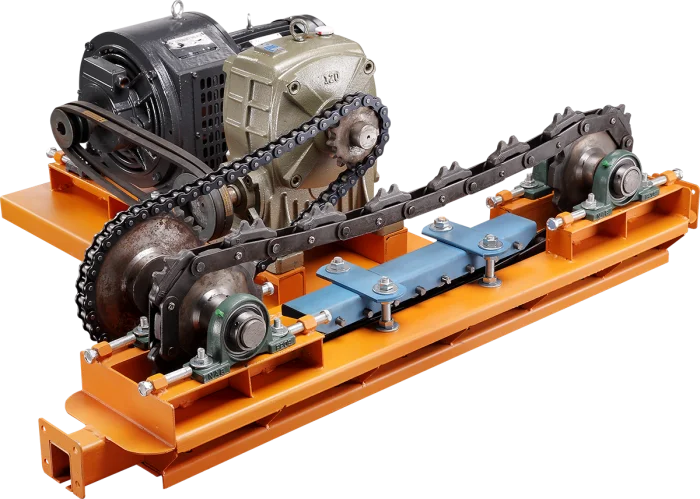

| Caterpiller driver device |

Two types-Standard type and heavy duty type. The driving device adjust the momentum that the motor ouput, after speed reduction unit increase its power which is to be passed to the driver caterpiller, the pusher dogs on which transport the chain so that chain can move forward. Stable conveying, little noise, highly reliable conveying force and speed. |

|

| Hanger |

Several types hangers: Cross type hanger; Y type hanger; I type hanger; Sprocket wheel hanger; U-type hanger; Bearing hanger; |

|

| Automatic oil sprayer |

Specially designed for various automatic conveying chain; More convenient to check oil-feeding diyusyion nsdrf upon oil volume in the transparent oil pipes. |

|

We also have I-beam cast conveyor chain X348, X458, X678.

Ms. Kathy Tang

Mobile, Whatsapp, Wechat: 0086-18423473470

Skype: tyc9744

-

10A-3 50-3 RS50 15.875mm pitch China made OEM three row transmission bush roller chain

-

Professional Wholesale Price Double Plus Chain Drive Chain and Conveyor Chain China Carbon OEM Custom Steel Long

-

Agricultural conveyor roller chain CA550 10 FT, RCC50-0014, CLCA550, 042-CA550CL

-

SS12A - A1 K1 RS60 SS12B Free Sample 304 Stainless Steel Conveyor Roller Chain Belt Accessories

-

Screw Conveyor 1873FH-K1600 Plastic Top Friction Chain,

-

Lubrication-free chain ice cream quick-freezing tunnel chain

-

conveyor roller chain for conveyor equipment

-

Original Tsubaki Chain Roller Chain M Type Knuckle Link High Quality Made in Japan

-

High Quality Roller Chain 35,40,41,50,60,80,100 Transmission Roller Chain Two Step Roller Chain Parts

-

Heavy Duty Big Chain Stainless Steel C2052/C2062/C2082 Carbon Steel Industrial Flex Plate Chain

Other Products

-

$17.00 / meter

$17.00 / meter -

$40.00 / piece

$40.00 / piece -

$40.00 / piece

$40.00 / piece