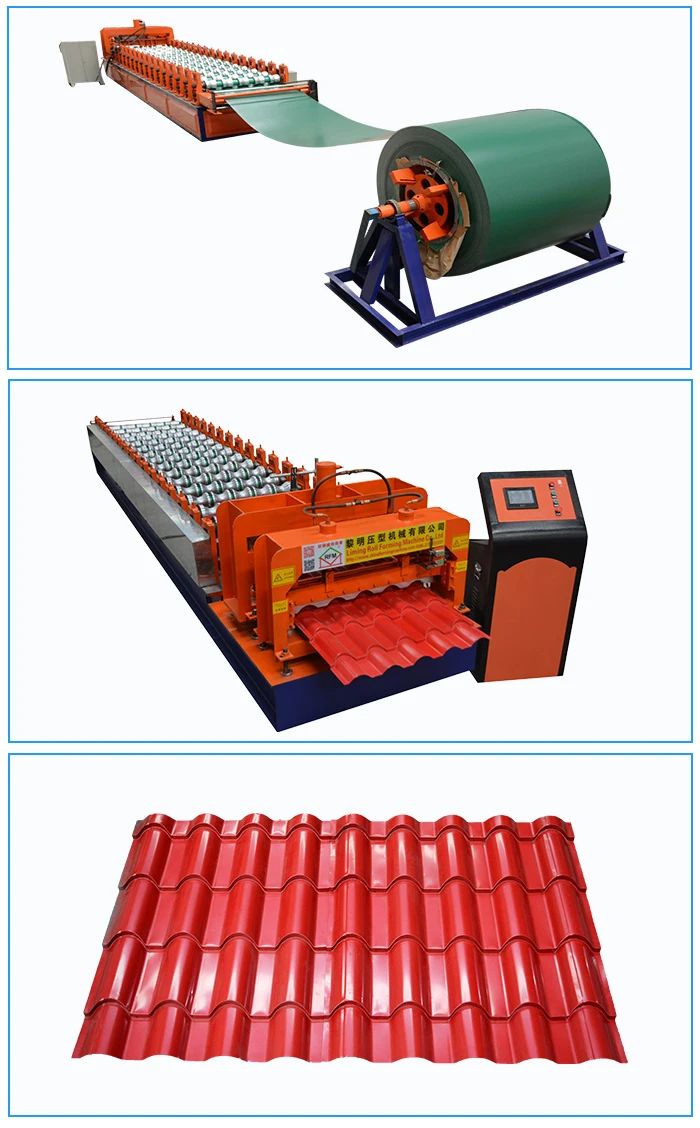

africa glazed tile aluminium roofing panel making roll forming machine

-

Supplier: Liming Stamping Form Machine Co., Ltd. -

Region: Hebei, China -

Contact: Mr TAO LI -

Price: $8000.00 / 1 - 1 sets

$6000.00 / 2 - 2 sets

$5000.00 / 3 - 4 sets

$4500.00 / >=5 sets -

Min. Order: 1 set

| Key Selling Points: | High Safety Level; | Showroom Location: | Philippines,Peru,Indonesia,Russia,Sri Lanka,South Africa,africa; |

| Warranty of core components: | 1 Year; | profiles: | as customers requirement; |

| operate style: | automatic; | Supply Ability: | 100 Sets per Year; |

| Machinery Test Report: | Provided; | Video outgoing-inspection: | Provided; |

| Feeding width: | 1250mm; | Warranty: | 2 years; |

| Package Preview: | ; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| raw material: | ppgi; | feeding width: | as customers requirement; |

| Marketing Type: | New Product 2020; | plc: | MITSUBISHI/DELTA/SIEMENS; |

| Port: | TIANJIN/XINGGANG Port; | Packaging Detail: | for the whole production line of roof tile production line, the main machine and its components are fastened in one 40-feet container; |

| Production Capacity: | 10-20m/min; | Rolling thinckness: | 0.3-0.7mm; |

| Applicable Industries: | Building Material Shops,Construction works ; | motor brand: | china famous brand; |

| Condition: | New; | Brand Name: | RFM; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | thickness: | 0.3-0.7mm; |

| Weight: | 4500 kg; | Dimension(L*W*H): | 7500*1500*1300Mm; |

| Place of Origin: | Hebei, China; | color: | Customized; |

| Type: | Tile Forming Machine; | Core Components: | Pressure vessel,Motor,Bearing; |

| Voltage: | 380V Or As Customize; | Tile Type: | Steel; |

| cutting blade material: | cr12 with quenched treatment; | Use: | ROOF; |

Customized Roof Sheet Forming Machines with Various Feed Widths

Technical Parameters:

|

No. |

Item |

Specification |

|

1 |

Can Formed Material |

PPGI,GI,AI |

|

2 |

Equipment operation |

Automatic |

|

3 |

Voltage |

380V 50Hz 3Phase or as your requirement |

|

4 |

Thickness of sheet (mm) |

0.3-0.7mm |

|

5 |

Material width(mm) |

As your requirement |

|

6 |

Cover Width of the sheet after formed |

as your drawing |

|

7 |

The size of the roll forming machine |

7500mmx1500mmx1300mm |

|

8 |

Speed |

8-15m/min |

|

9 |

Diameter of shaft |

70mm |

|

10 |

Weight of the Machine |

4200-4600KGS |

|

11 |

Material of rollers |

C45 steel quenched and chromed |

|

12 |

Motor brand |

Siemens or Guomao |

|

13 |

PLC |

Siemens or Delta or Mitsubushi |

|

14 |

Total power (kw) |

8kw |

|

15 |

Power of hydraulic system |

4kw |

|

16 |

Power of main molding core |

4kw |

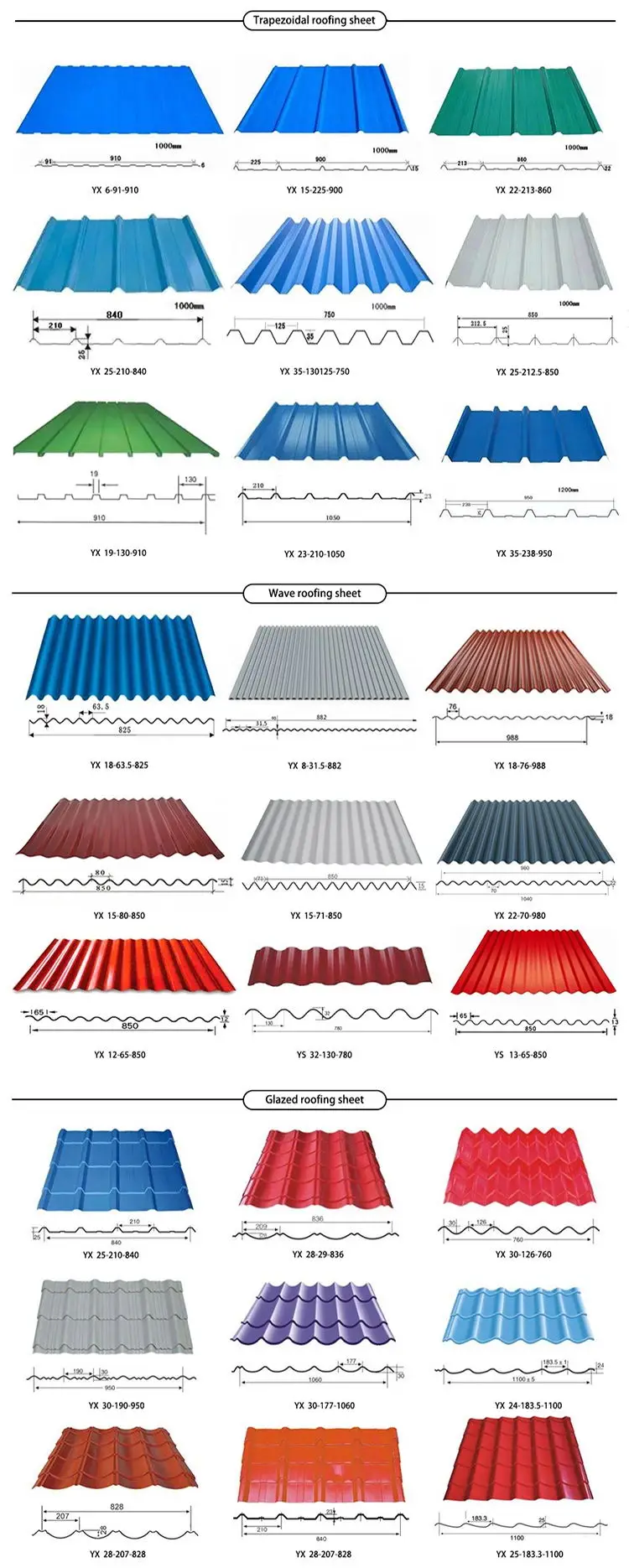

Metal Roof Trapezoid Corrugated Iron Roof Sheet Roll Forming Machine Product Size Reference

|

Roof tile forming machine configuration components |

||

|

Name |

Quantity |

Units |

|

3T manual uncoiler |

1 |

Set |

|

Adjustable feeding platform |

1 |

Set |

|

Roll forming system |

1 |

Set |

|

Cut Equipment |

1 |

Set |

|

Hydraulic system |

1 |

Set |

|

Electric control system |

1 |

Set |

|

Supporter/Automatic Stacker |

1 |

Set |

| Send Inquiry Now |

For more information,welcome to visit our website: www.chinaformingmingmachine.com

![]()

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa