5G mobile phone FR4 PCB manufacturer Shenzhen

-

Supplier: Shenzhen Wonderful Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Miss Gong -

Price: $0.10 /piece -

Min. Order: 1 piece

Product details

| Applied for: | water heater, fitness, LED light, Fan heater; | Copper Thickness: | 0.5oz; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,paypal; | Outer packing: | Standard carton box, with bulb package; |

| Port: | shenzhen or HK; | Legend color: | white; |

| Board Thickness: | 1.6mm; | Min. Line Width: | 4mil/0.1mm; |

| Place of Origin: | Guangdong, China; | Min. Hole Size: | 0.2mm; |

| Type: | Double Sided PCB; | Inner packing: | Vacuumn package, with dryer; |

| Base material: | FR4, H-TG, Teflon, Rogers, Aluminium, copper base; | Surface Finishing: | ENIG; |

| Assembly service: | OEM service to all kinds of printed circuit board assembly; | Solder mask color: | green; |

| Serivice range: | engineering support, fast turn prototype, fast mass production; | Brand Name: | Wonderful PCB; |

| Packaging Detail: | Our circuit board pcb packaging: vacuum packing: Inner packing: Vacuum package, with dryer Outer packing:Standard carton box, with bulb package; | Min. Line Spacing: | 0.1mm4mil); |

| Model Number: | 4 Layer pcb; | Board Size: | OEM; |

| Supply Ability: | 40000 Square Meters per Month; | Specialized in: | high-precision, high-density, double-sided PCB, multilayer PCBA; |

| PCB Test: | Flying probe test, high-stingency 100% visual inspection; | Base Material: | FR4 TG130; |

One-Stop OEM Service

If desired, we will source, organise and manage all aspects of the PCB design, so that your product meets all required standards and is fully optimised for easy and cost effective manufacturing.

A well designed circuit board means:

· A reduction in production problems

· Improved quality control

· Reduced costs

· Reduced manufacturing times

We work to supply small and large batches of competitively priced printed circuit boards to our customers.

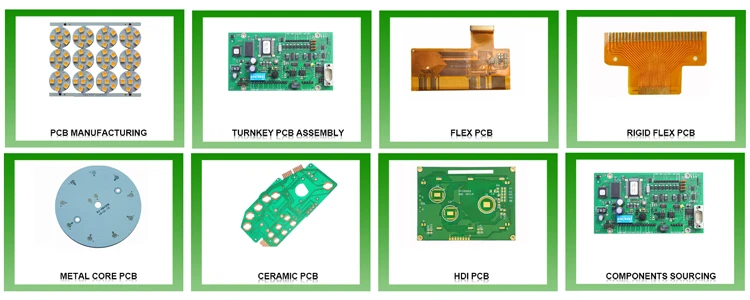

PCB&PCBA Capabilitise

PCB Capability | ||||||||

Number of Layer | 1 - 20 Layer | |||||||

Maximum Processing Area | 680 × 1000MM | |||||||

Min Board Thickness | 2 Layer - 0.3MM ( 12 mil ) | |||||||

4 Layer - 0.4MM ( 16 mil ) | ||||||||

6 Layer - 0.8MM ( 32 mil ) | ||||||||

8 Layer - 1.0MM ( 40 mil) | ||||||||

10 Layer - 1.1MM ( 44 mil ) | ||||||||

12 Layer - 1.3MM ( 52 mil ) | ||||||||

14 Layer - 1.5MM ( 59 mil ) | ||||||||

16 Layer - 1.6MM ( 63 mil ) | ||||||||

18 Layer - 1.8MM ( 71 mil ) | ||||||||

Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM | |||||||

1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | ||||||||

Twisting and Bending | ≤ 0.75%, Min: 0.5% | |||||||

Range of TG | 130 - 215 ℃ | |||||||

Impedance Tolerance | ± 10%, Min: ± 5% | |||||||

Hi-Pot Test | Max: 4000V/10MA/60S | |||||||

Surface Treatment | HASL, With Lead, HASL Free Lead | |||||||

Flash Gold, Immersion Gold | ||||||||

Immersion Silver, Immersion Tin | ||||||||

Gold Finger, OSP | ||||||||

PCB Assembly Capability | PCB Assembly Capability | |||||||

Order Quantity | 1pc – 10,000,000+pcs | |||||||

Build Time | 1 – 5 days, 1 – 2 weeks, or scheduled deliveries | |||||||

PCB Spec Requirements | PCB whose width/length is less than 30mm should be panelized Max board size: 500×450 mm Board Type: Rigid PCBs, Flexible PCBs, Metal core PCBs Surface finish: lead/lead-free HASL, ENIG, Silver, OSP | |||||||

Assembly Types | Surface mount Thro-hole Mixed technology (SMT & Thru-hole) Single or double sided placement Conformal coating Shield cover assembly for EMI emission control | |||||||

Solder Type | Lead-free – RoHS | |||||||

Parts Procurement | Full Turnkey Partial Turnkey Kitted/Consigned | |||||||

Component types | SMT 01005 or larger BGA 0.4mm pitch, POP (Package on Package) WLCSP 0.35mm pitch Hard metric connectors Cable & wire | |||||||

SMT Parts Presentation | Bulk Cut tape Partial reel Reel Tube Tray | |||||||

Stencils | Laser-cut stainless steel | |||||||

Other Techniques | Free DFM Review Box Build Assembly 100% AOI test and X-ray test for BGA IC programming Components cost-down Function test as custom Protection technology | |||||||

It can be a challenge to find the optimal supplier for PCBs – meeting each and all customers’ expectations and requirements on price, quality, lead times, value-added services, and delivery. Wonderful PCBs is confidant that we meet each and every expectations for your each PCB.

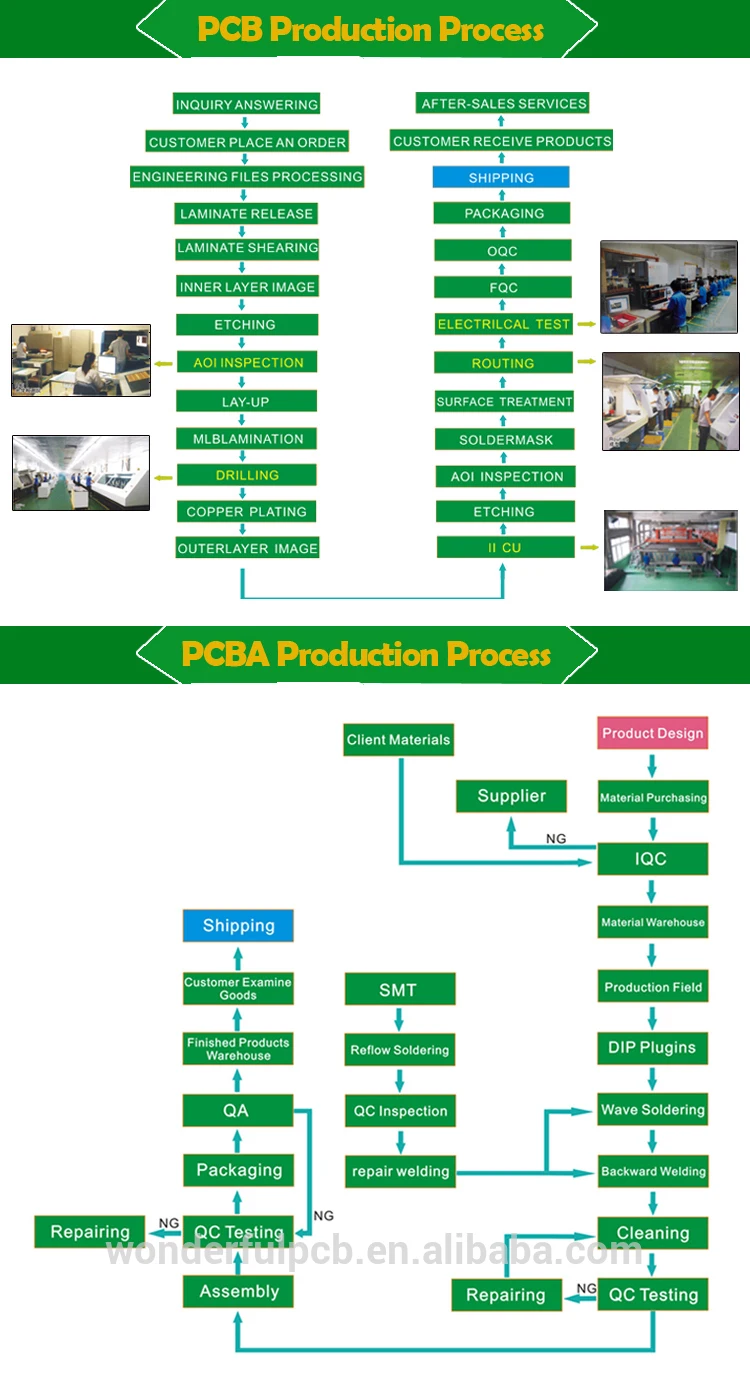

Production Flow

Our advantage | ||||||||

Material Technology | Our Production | General Production | ||||||

Regular/Special | 1.Our (TG170)FR4: high quality materials, excellent heat resistance, won't distort break in high temperature, no foaming, no burning, good performance in electrical charge, impact resistance, humidity-resistance 2.Our FR4 good performance in electrical charge, impact resistance, humidity-resistance 3.Our CEM no-burr 4.Our Rogers Good performance in high frequency 5.Our Aluminum Excellent heat dispersion | 1.General FR4 High heat work 2.General CEM Expand and deform in damp conditions | ||||||

Factory | We have automatic production line. The automatic production line improves the precision and efficiency of PCB producing,it makes surface brighter, cleaner and more smooth, and it helps reduce the cost. | Artificial production line | ||||||

Blind/buried via board, High Density Interconnect(1+1,N+1) | Application of HDI technology reducing the thickness and the volume of PCB boards, increasing the density of 3-D wiring design. | Difficult manufacturer, high cost | ||||||

Impedance | Good performance in reliability and stability of signal sending and receiving | High cost | ||||||

Surface Technics | 1.IMG:smooth surface, good adhesion, no oxidation under long using 2.gold plating(thick gold:1-50U"):good wear-resistance 3.HASL:better price, not easy oxidation, easy to welding, smooth surface 4.HAL: better price, not easy oxidation, easy to welding | 1.IMG:high price 2.Gold plating(thick gold):high price 3.HAL:surface is not flat, not suitable for BAG packaging | ||||||

Copper Via/Surface(20-25UM,0.5-60Z) | Laser holing: Min 0.1MM, Mechanical holing: Min 0.2MM | Hard to reach 0.1MM | ||||||

Multilayer board(4-20 L),BGA(CPU) | BGA:high density, high performance, multifunctional, increase thermal reliability, good performance in electroheat property, MIN width/space: 3/3MIL Multilayer board:strong microporous, high reliability | Difficult manufacturer,high cost | ||||||

Test | To assure quality, avoid wasting after installing and scraping, save cost, save the time of rework | Careless | ||||||

About Us

Contact Us

VIEW MORE

You may like

-

Customized single sided round aluminum substrate, 12v led light circuit board factory

-

Support professional double-sided PCB design one-stop OEM service

-

Custom electronics contract manufacturing double sided pcb assembly

-

Wholesale Lighting Led Pcb Led Board Design Led Circuit Board 3535 5730 3w 5w 7w 9w 12w 15w 18w Smd LED Printed Circuit Board

-

Free Shipping 100% Original HDD PCB Logic Board 2060-800041-003 REV P1 Hard Drive Circuit Board 2060-800041-000 REV P1

-

best china kb 3151c fr-1 pcb with rohs long life

-

China Printed Circuit Board Automotive Mobile Medical PCBA Assembly PCB Design Service

-

RDS Electronics- Circular board PCB aluminum factory MCPCB 2835 LED SMD 5630 aluminum PCB

-

Shenzhen ODM double-sided PCB designer and Customized PCB Manufacturer

-

PCB Substrate FR4 94v-0 PCB Circuit Board Manufacturer

Other Products

-

$0.10 / piece

$0.10 / piece -

$0.50 / piece

$0.50 / piece -

$0.35 / piece

$0.35 / piece -

$0.10 / piece

$0.10 / piece -

$2.90 / piece

$2.90 / piece -

$0.30 / piece

$0.30 / piece

Related Search

pcb manufacturer shenzhen

mobile phone charger pcb board

shenzhen mobile phone iphone 5 complete

mobile phone pc manufacturers suppliers

mobil phone cabl manufactur suppliers

mobile phone pcb circuit board suppliers

6 sim card mobile phone

keypad mobile phone

mobile phones

dual sim mobile phone digital mobile