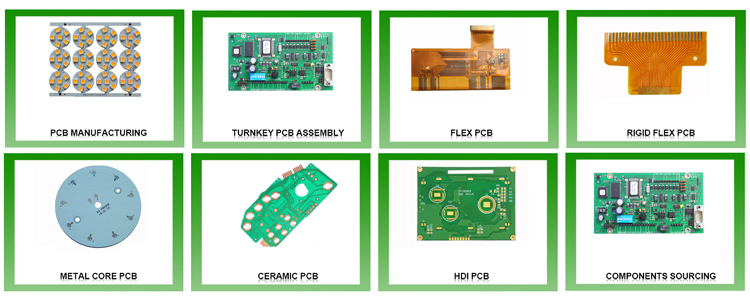

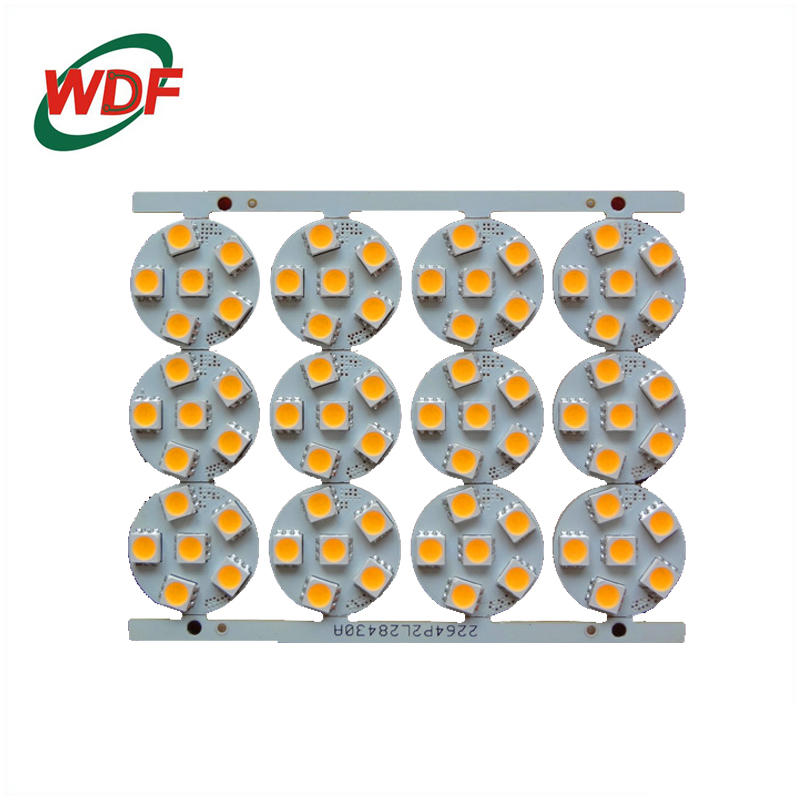

Professional Chinese OEM Manufacturing PCB PCB Board PCB 94v0 LED Aluminum PCB

-

Supplier: Shenzhen Wonderful Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Miss Gong -

Price: $0.10 /piece -

Min. Order: 1 piece

Product details

| Finished board: | Thickness: ≤1.0MM, Tolerance: ±0.1MM | Origin: | Guangdong, China |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal | Twist and bend: | ≤0.75%, min: 0.5% |

| port: | Shenzhen, Hong Kong | Packaging Details: | Inner packing: vacuum packing/polybag Outer packing: standard carton packing |

| Board size: | Processing | Certificate: | ISO9001.ROSH.UL |

| Supply capacity: | 45000 square meters wonderful aluminum PCB manufacturer per month | Surface treatment: | Leaded/lead-free HASL, immersion gold, silver, OSP |

| Maximum processing area: | 680×1000MM | minute. line width: | 0.1 mm |

| Substrate: | aluminum | Silk screen color: | black, white, red, green |

| brand: | Wonderful PCB | Thermogravimetric range: | 130-215℃ |

| Serve: | One-stop OEM service | MOQ: | 1 |

| Plate thickness: | 0.3mm- 4mm | Copper thickness: | 0.3 - 6 oz |

| Layers: | 1-28 floors | type: | Aluminum plate |

| thing: | Excellent aluminum substrate manufacturer | model: | wonderful aluminum substrate |

| minute. Hole size: | 0.2mm | minute. Line spacing: | 0.1 mm |

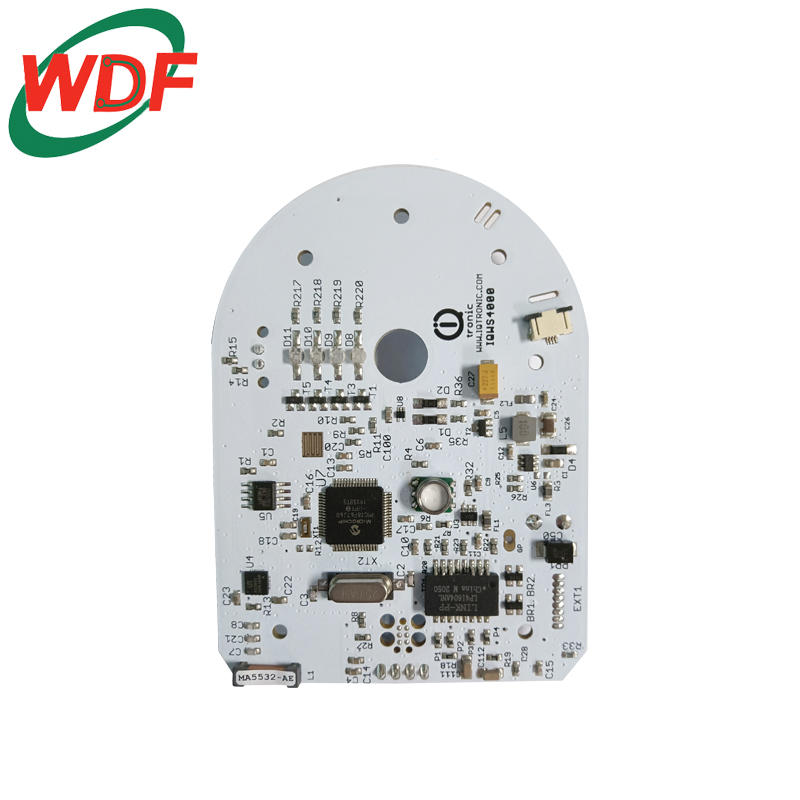

One-stop OEM service

If required, we will source, organize and manage all aspects of PCB design so that your product meets all required standards and is fully optimized for easy and cost-effective manufacturing. Well-designed boards mean: Fewer production issues Improved quality control Reduced costs Reduced manufacturing timeWe are committed to providing customers with competitively priced printed circuit boards in both small and large quantities.

PCB&PCBA capability

Finding the best PCB supplier can be a challenge that meets each customer's expectations and requirements in terms of price, quality, lead time, value-added services and delivery.Wonderful PCBWe are sure we can meet your every expectation with every PCB.

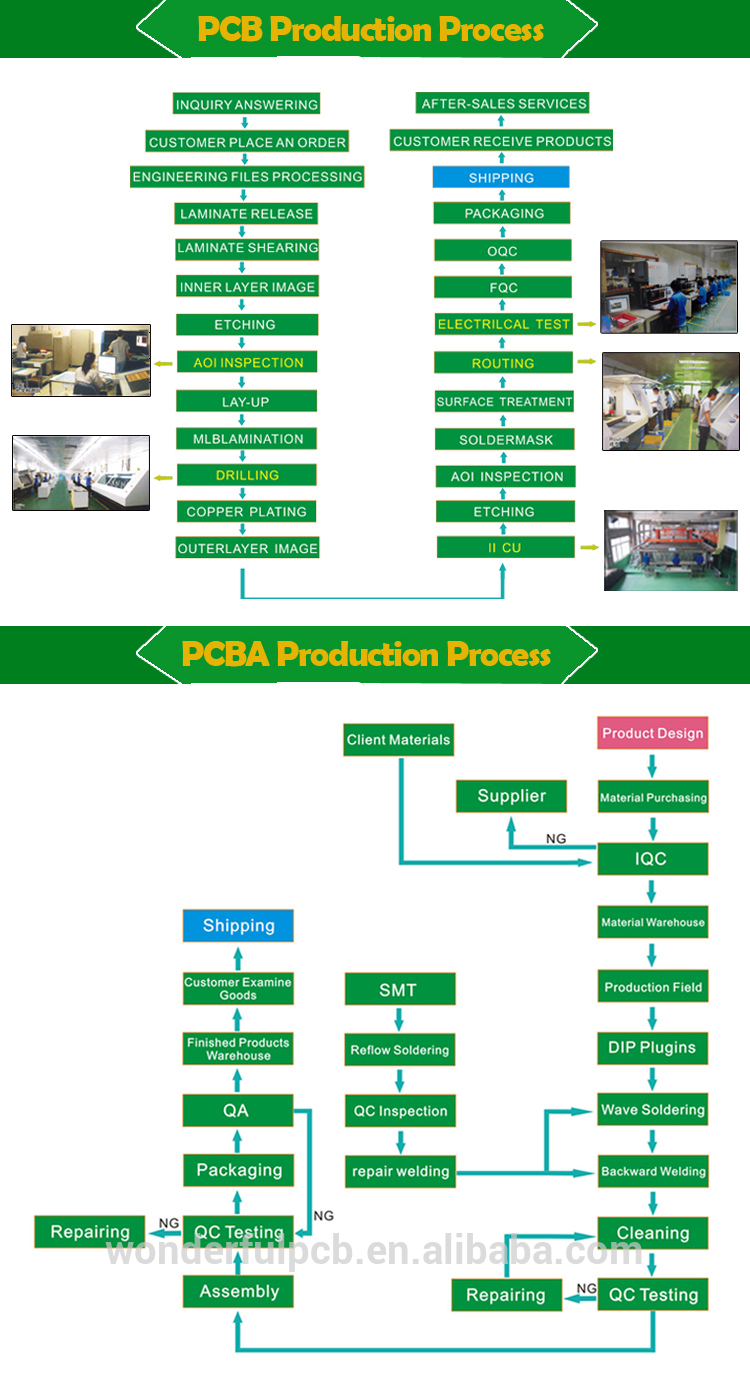

Production Process

Our advantage | ||||||||

material technology | our production | General production | ||||||

regular/special | 1. Our (TG170) FR4: High-quality materials, excellent heat resistance, no deformation and fracture at high temperature, no foaming, no burning, good performance Chargeability, impact resistance, moisture resistance 2. Our FR4 Good performance of electrification, impact resistance and moisture resistance 3. Our CEMs No glitch 4. Our Rogers good high frequency 5. Our aluminum Excellent heat dissipation | 1. General FR4 Hot work 2. General CEM Swells and deforms in wet conditions | ||||||

factory | We have automatic production lines. The automated production line improves the accuracy and efficiency of PCB production, making The surface is cleaner and smoother, which is beneficial to reduce costs. | Manual production line | ||||||

Blind/Buried Via Board, High Density Interconnection (1+1, N+1) | The application of HDI technology reduces the thickness and volume of the PCB board and increases the density of 3D wiring design. | Production is difficult and costly | ||||||

impedance | Good reliability and stability of signal sending and receiving | high cost | ||||||

Surface Technology | 1. IMG: smooth surface, good adhesion, long-term use without oxidation 2. Gold plating (thick gold: 1-50U"): good wear resistance 3. HASL: better price, not easy to oxidize, easy to weld, smooth surface 4. HAL: better price, not easy to oxidize, easy to weld | 1. IMG: high price 2. Gold plating (thick gold): high price 3. HAL: The surface is uneven, not suitable for BAG packaging | ||||||

Copper hole/surface (20-25UM,0.5-60Z) | Laser drilling: minimum 0.1MM, mechanical drilling: minimum 0.2MM | It is difficult to reach 0.1MM | ||||||

Multi-layer board (4-20L), BGA (CPU) | BGA: high density, high performance, multi-function, increased thermal reliability, good electrothermal performance, MIN Width/Space: 3/3MIL Multi-layer board: strong micro-hole, high reliability | Production is difficult and costly | ||||||

test | Guarantee quality, avoid waste after installation, save cost and rework time | careless | ||||||

about Us

contact us

VIEW MORE

You may like

-

China 94v0 LED PCB manufacturing PCBA prototype cheap price LED led pcba panel SMD light circuit PCB

-

Customized 9w 12w 15w 18w Led light bulb PCB round panel assembly 12v 24v SMD 5050 5730 2835 5630 LED PCBA aluminum base circuit board

-

China Reliable and Custom PCB Supplier with high quality electronic pcb aluminum plate

-

2Layers Aluminum Core PCB

-

LED Pcb Manufacturing Lamp Accessories Mcpcb Board Aluminum Pcb Board

-

Best Selling 30w-50w Aluminum Micro SMD LED Light PCB Board

-

SMD5050 7700 lm aluminum plate flood tunnel light street light led module pcb

-

China Aluminum LED Bulb PCB, SMD LED Custom PCB OEM ODM Circuit Board For DOB Bulb

-

Bulb lamp pcba design chip patch led PCB bulb lamp circuit board

-

Samsung LM301H 301B plant light assembly pcb with LED PCB module circuit board plant light PCBA

Other Products

-

$0.50 / piece

$0.50 / piece -

$0.35 / piece

$0.35 / piece -

$0.10 / piece

$0.10 / piece -

$0.10 / piece

$0.10 / piece -

$2.90 / piece

$2.90 / piece -

$0.30 / piece

$0.30 / piece

Related Search

manufactured pcb

led aluminum pcb mount suppliers

led aluminum pcb cutting

pcb board manufactures

mp3 player pcb circuit board manufacturer

professional pcb board industry

good professional pcb manufacturer

tv box 94v0 pcb circuit board manufacturers

circuit boards pcb manufacturing

pcb circuit boards