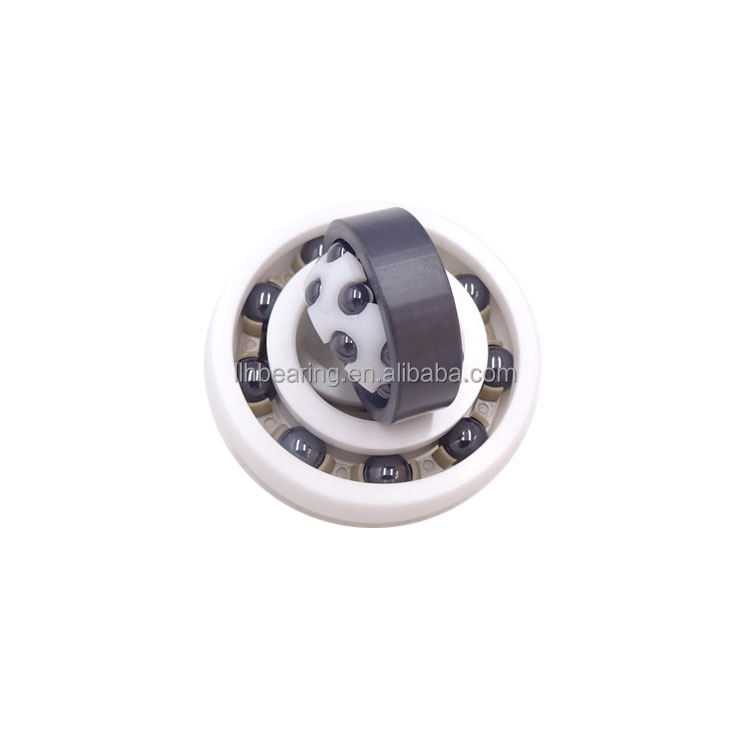

Complete high quality 6206 ceramic / hybrid bearings, plastic bearings

-

Supplier: Jinan Maolei Bearing Co., Ltd. -

Region: Shandong, China -

Contact: Ms jiessie zhang -

Price: $22.00 / 10 - 99 pieces

$10.00 / >=100 pieces -

Min. Order: 10 pieces

| Packaging Details: | A: barrel + outer box + pallet B: single box + outer box + pallet C: tube package + medium; | Material: | Ceramic Si3N4 ZrO2; |

| place of origin; place of origin: | China; | application: | medical equipment; |

| brand: | LLH or OEM; | payment terms: | L/C,D/P,D/A,T/T,MoneyGram,Official Bank Account/Paypal; |

| type: | ceramic ball; | Serve: | OEM customized service; |

| lubricating: | grease; | Accuracy class: | P0 P6 P5 P4; |

| Applicable industries: | energy and mining; | Seal Type: | Open Zz Rs Zrs; |

| port: | Qingdao or at your request; | product name: | Customized ceramic bearings; |

| Supply capacity: | 100,000 pieces per month; | model: | 6206; |

Mass Custom Ceramic Bearings China Manufacturer

Full ceramic bearing introduction:

All ceramic bearings have antimagnetic insulation, wear resistance,

Oil-free self-lubricating, resistant to extreme high or low temperatures, can be used for

Harsh environments, even under certain special conditions. The material of the rings and rollers are cans

gonia (ZrO2) and stents use polyfluoro-backed (PTFE) as standard. Generally speaking,

We can use glass fiber 66 (GRPA66-25), reinforced nylon made of special engineering plastics

(PEEK, PI), stainless steel (AISI SUS316 SUS304), brass (Cu), etc. Ceramic deep groove ball

Bearings are made entirely of ceramic material, superior to ordinary steel angular contact

Bearings are in many ways. Ceramics are the perfect material for any application looking for higher performance

RPM, to reduce overall weight or for use in extremely harsh environments where high temperatures and

Corrosive substances are present.

Advantages of ceramic deep groove ball bearings:

1) Ceramic bearings have the characteristics of corrosion resistance, and ceramic rolling bearings are suitable for

For operation in harsh conditions covered with corrosive media.

2) Since the density of ceramic balls is lower than that of steel, they are lighter, so when you

The centrifugal effect of the rotating outer ring can be reduced by 40%, thereby greatly extending the service life

Life.

3) The expansion and contraction effects of ceramics are smaller than those of steel, so

The bearing clearance is constant, and the bearing allows for harsher environments with temperature changes.

4) Since the elastic modulus of ceramics is higher than that of steel, it is not easy to deform when subjected to force.

This contributes to increased operating speed and high accuracy.

plastic bearingintroduce:

plastic bearingintroduce:

POM plastic bearings, PP plastic bearings POM and PA materials have good mechanical strength and wear resistance, and are suitable for the production of more precise plastic bearings. The working temperature is from -60°C to 100°C, with high strength and smooth surface. Appearing tension, its good self-lubricating properties and low friction coefficient, on the basis of maintaining the traditional advantages of plastic bearings, are precise and can be used for high-speed operation

Related models

|

Bearing number |

size |

Installation size (mm) |

northwest |

northwest |

|||||

|

mm |

Big |

Big |

Big |

pull |

(Kilogram) |

(refer to) |

|||

|

d |

D |

Second |

minute |

maximum |

maximum |

maximum |

Zirconia |

Si3N4 |

|

|

6800CE |

10 |

19 |

5 |

12 |

12 |

17 |

0.3 |

0.004 |

0.0021 |

|

6900CE |

|

twenty two |

6 |

12 |

12.5 |

20 |

0.3 |

0.007 |

0.0038 |

|

6000 AD |

|

26 |

8 |

12 |

13 |

twenty four |

0.3 |

0.014 |

0.0075 |

|

6200CE |

|

30 |

9 |

14 |

16 |

26 |

0.6 |

0.025 |

0.013 |

|

6300CE |

|

35 |

11 |

14 |

16.5 |

31 |

0.6 |

0.04 |

0.022 |

|

6801CE |

12 |

twenty one |

5 |

14 |

14 |

19 |

0.3 |

0.005 |

0.0025 |

|

6901CE |

|

twenty four |

6 |

14 |

14.5 |

twenty two |

0.3 |

0.008 |

0.0042 |

|

16001CE |

|

28 |

7 |

14 |

/ |

26 |

0.3 |

0.015 |

0.0079 |

|

6001CE |

|

28 |

8 |

14 |

15.5 |

26 |

0.3 |

0.017 |

0.0092 |

|

6201CE |

|

32 |

10 |

16 |

17 |

28 |

0.6 |

0.028 |

0.015 |

|

6301CE |

|

37 |

12 |

17 |

18 |

32 |

1 |

0.046 |

0.025 |

|

6802CE |

15 |

twenty four |

5 |

17 |

17 |

twenty two |

0.3 |

0.005 |

0.0029 |

|

6902CE |

|

28 |

7 |

17 |

17 |

26 |

0.3 |

0.012 |

0.0063 |

|

16002 AD |

|

32 |

8 |

17 |

/ |

30 |

0.3 |

0.021 |

0.011 |

|

6002CE |

|

32 |

9 |

17 |

19 |

30 |

0.3 |

0.024 |

0.013 |

|

6202CE |

|

35 |

11 |

19 |

20.5 |

31 |

0.3 |

0.035 |

0.019 |

|

6302CE |

|

42 |

13 |

20 |

22.5 |

37 |

1 |

0.064 |

0.035 |

|

6803CE |

17 |

26 |

5 |

19 |

19 |

twenty four |

0.3 |

0.005 |

0.0029 |

|

6903CE |

|

30 |

7 |

19 |

19.5 |

28 |

0.3 |

0.013 |

0.0071 |

|

16003 AD |

|

35 |

8 |

19 |

/ |

33 |

0.3 |

0.025 |

0.014 |

|

6003CE |

|

35 |

10 |

19 |

21.5 |

33 |

0.3 |

0.032 |

0.017 |

|

6203CE |

|

40 |

12 |

twenty one |

23.5 |

36 |

0.6 |

0.052 |

0.028 |

|

6303CE |

|

47 |

14 |

twenty two |

25.5 |

42 |

1 |

0.087 |

0.047 |

|

6403CE |

|

62 |

17 |

23.5 |

/ |

55.5 |

1 |

0.21 |

0.11 |

|

6804CE |

20 |

32 |

7 |

twenty two |

22.5 |

30 |

0.3 |

0.013 |

0.007 |

|

6904CE |

|

37 |

9 |

twenty two |

twenty four |

35 |

0.3 |

0.028 |

0.015 |

|

16004 AD |

|

42 |

8 |

twenty two |

/ |

40 |

0.3 |

0.037 |

0.02 |

|

6004CE |

|

42 |

12 |

twenty four |

25.5 |

38 |

0.6 |

0.052 |

0.028 |

|

6204CE |

|

47 |

14 |

25 |

26.5 |

42 |

1 |

0.082 |

0.045 |

|

6304CE |

|

52 |

15 |

26.5 |

28 |

45.5 |

1 |

0.11 |

0.06 |

|

6404CE |

|

72 |

19 |

26.5 |

/ |

65.5 |

1 |

0.31 |

0.17 |

|

6805CE |

25 |

37 |

7 |

27 |

27 |

35 |

0.3 |

0.016 |

0.009 |

|

6905CE |

|

42 |

9 |

27 |

28.5 |

40 |

0.3 |

0.032 |

0.018 |

|

16005 AD |

|

47 |

8 |

27 |

/ |

45 |

0.3 |

0.045 |

0.025 |

|

6005CE |

|

47 |

12 |

29 |

30 |

43 |

0.6 |

0.061 |

0.033 |

|

6205CE |

|

52 |

15 |

30 |

32 |

47 |

1 |

0.099 |

0.054 |

|

6305CE |

|

62 |

17 |

31.5 |

36 |

55.5 |

1 |

0.18 |

0.098 |

|

6405CE |

|

80 |

twenty one |

33 |

/ |

72 |

1.5 |

0.41 |

0.22 |

|

6806CE |

30 |

42 |

7 |

32 |

32 |

50 |

1 |

0.018 |

0.01 |

Our main products

Certification

company information

Jinan Maolei Bearing Co., Ltd.is a manufacturer and trader specialized in bearing research, development and production. It is located in Jinan, the "Spring City", with convenient transportation.

The core products of Jinan Maolei Bearing Co., Ltd. are deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, wheel hub bearings, linear bearings, bearing housing bearings, ceramic bearings, plastic bearings and other bearings. Bearings, cylindrical roller bearings, angular contact ball bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings and needle roller bearings to spherical plain bearings and other products. All our products comply with the international quality standard ISO 9001 and are highly appreciated in various different markets around the world.

We adhere to the business philosophy of "integrity" and "pragmatic win-win". We also adhere to the "people-oriented" and "enterprising" spirit of enterprise. "Quality first, customer first" is our corporate philosophy.

our service

1. High speed, high precision, low noise, long life

2. Wide application

3. Large inventory

4. Small order accepted

5. Competitive price and high quality

6. Various brands

7. Requires very little maintenance

8. Support OEM

9. The company adheres to the business philosophy of "quality first, credit first", and the product specifications are complete. We enjoy a high reputation in the international market with perfect service and sufficient supply.

FAQ

Q: Are you a trading company or a manufacturer?

A: We have been engaged in bearing manufacturing for more than 20 years, "Quality is our culture".

Q: How long is your delivery time?

A: If the goods are in stock, usually 1-3 days. Or 15-20 days if the goods are not in stock, depending on the quantity.

Q: What is the cause of bearing noise?

A: Bearing noise is related to the bearing and how it is used. Some external factors that affect bearing noise include the type of lubricant, excessive bearing load and improper installation. Once there is abnormal noise, you can contact our engineers, we will help you find the cause and provide corresponding solutions.

Q: What are your payment terms?

A.100%T/T

B. 30% T/T in advance, 70% against duplicate bill of lading (large order)

C. Western Union

D. Paypal

Any questions, please don't hesitate to contact us!

-

Fishing Reel Bearing 3x6x2.5mm Full Ceramic Bearing

-

motorcycle ball bearing 6004 6201 6202 6203 6300 6301 RS

-

High quality white Si3N4 uc203 uc204 uc205 uc206 ceramic insert bearing

-

High grade ball bearings abec9 zirconia zro2 si3n4 micro-ceramic 3x10x4 r8 r144 6204 608 full ceramic bearing

-

Cheap Bearings High Speed Ceramic Ball Bearings 12 32 10mm 6201 Bearings

-

BARDEN C34-5SSTY63 for TURBOVAC TW70 turbomolecular pump

-

New products 2018 NSK 608 ceramic ball bearings made in China

-

608 cageless ceramic bearing 608 full-fill ceramic high temperature resistant 1000 German 608 hybrid ceramic ball bearing without cage

-

Motor Ceramic Bearings SR2C-ZZ RC ZZ 3,175mm x 9,525mm x 3,967mm

-

Full Zirconia Ceramic Bearings 608z 6000 6001 6002 6003 6004 6005 High Speed Static Nylon Bearings Small Bearings

Other Products

-

$0.45 - $0.60 / piece

$0.45 - $0.60 / piece -

$1.00 - $1.50 / set

$1.00 - $1.50 / set -

$1.20 / unit

$1.20 / unit -

$1.50 - $3.00 / piece

$1.50 - $3.00 / piece -

$1.00 - $1.50 / piece

$1.00 - $1.50 / piece -

$0.25 - $0.50 / piece

$0.25 - $0.50 / piece -

$16.27 / set

$16.27 / set -

$4.50 - $6.52 / piece

$4.50 - $6.52 / piece -

$1.80 / set

$1.80 / set -

$1.25 / set

$1.25 / set