Fosita Hot Sale Plastic PVC UPVC Belling Socket Machine

-

Supplier: Suzhou Fosita Science And Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr YONGBING QIU -

Price: $5500.00 /set -

Min. Order: 1 set

| Dimensions (L*W*H): | accumulation | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Core Components Warranty: | 1 year | Packaging Preview: | |

| Supply capacity: | 5 sets per month | Packaging Details: | Standard package for hot selling general purpose automatic plastic pipe flaring machine. |

| port: | Shanghai | Health status: | new |

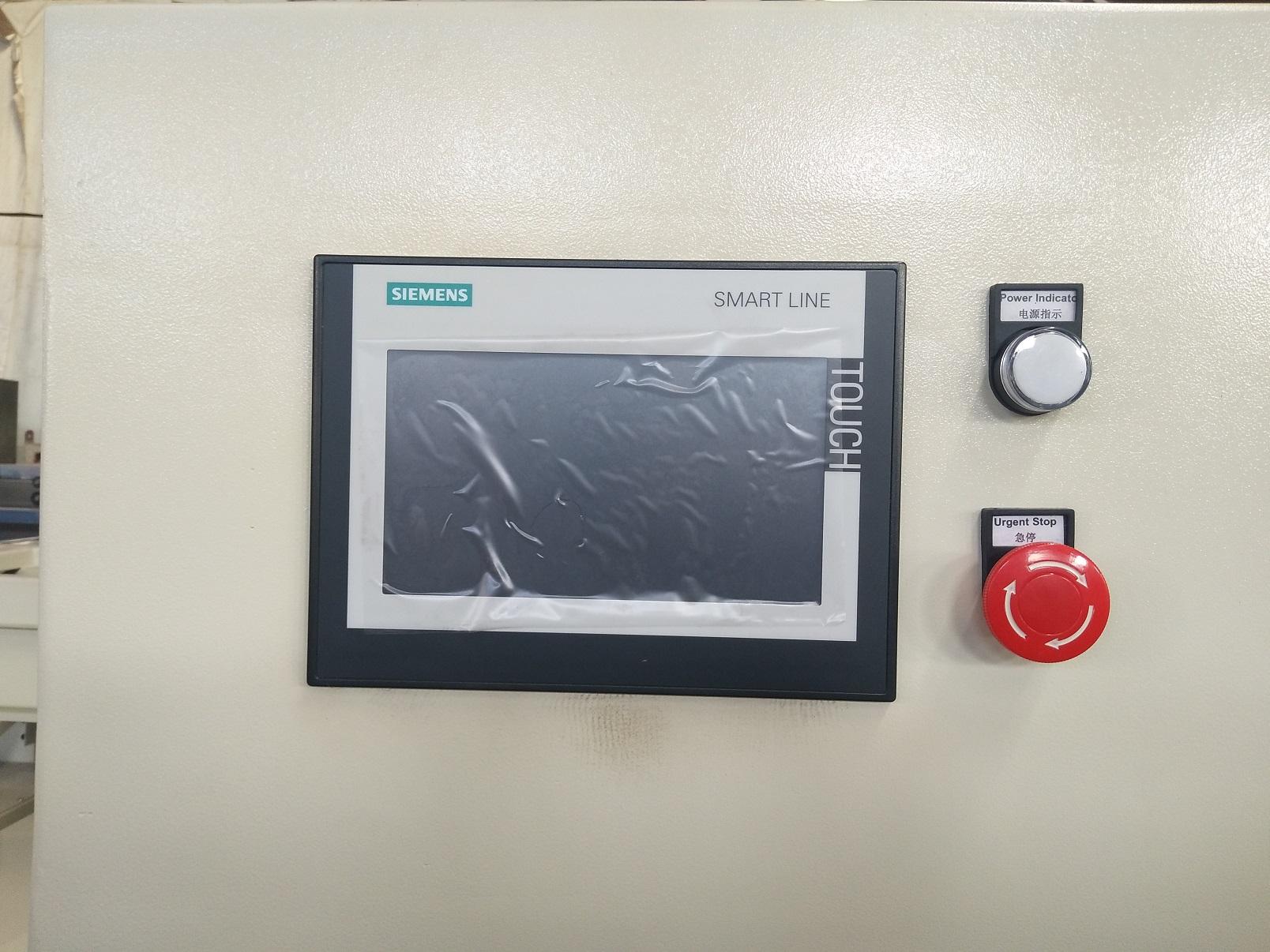

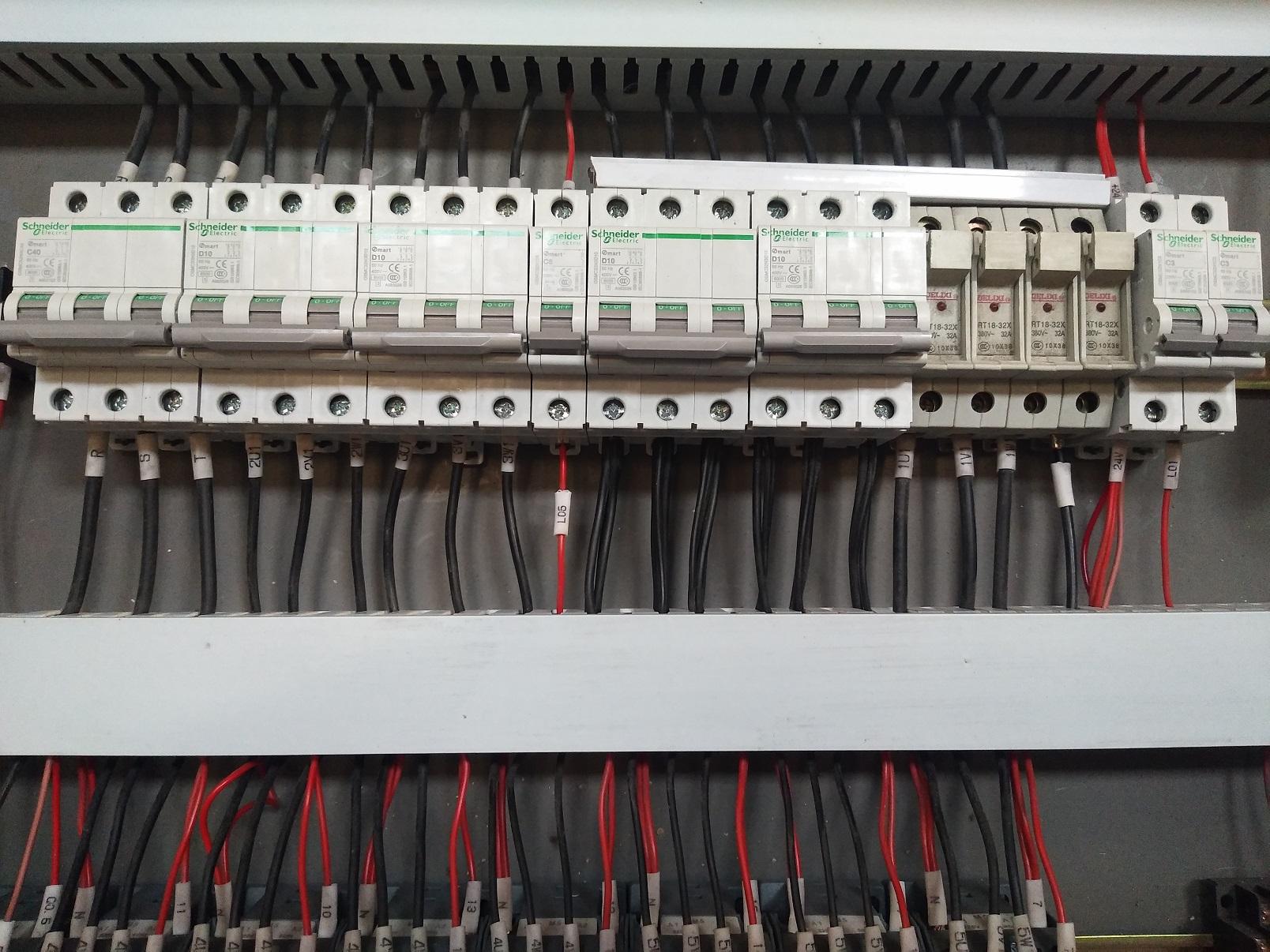

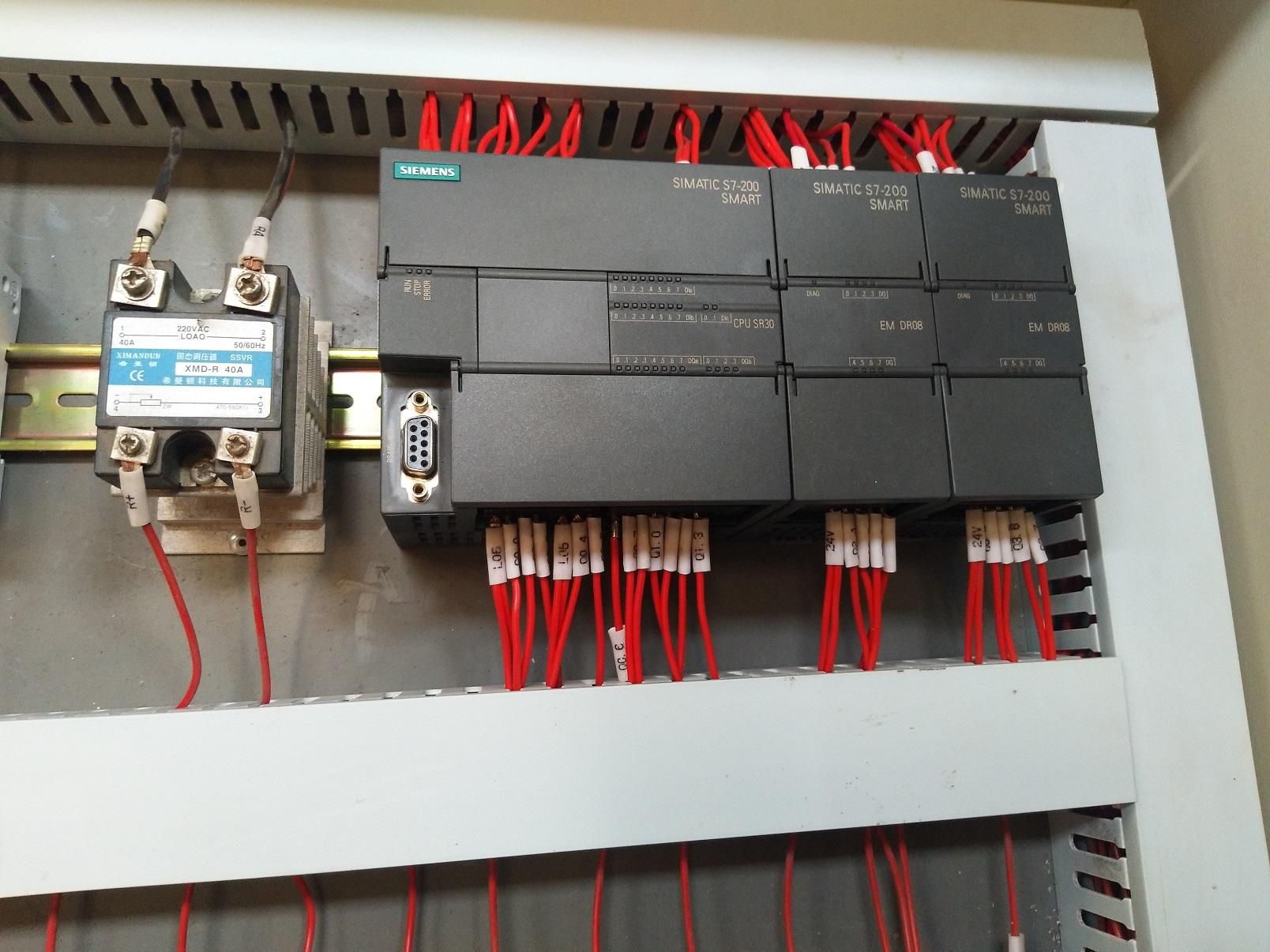

| Video external inspection: | if | Core components: | PLC, engine, motor |

| Applicable industries: | Manufacturing plants, mechanical repair shops, construction works, others | Pipe Length: | 200-1000mm |

| model: | SGK250 automatic plastic pipe flaring machine | Voltage: | 380V, 380V |

| Showroom location: | Egypt, Turkey, India | Certification: | Chief Executive |

| Product Category: | plastic pipe | weight: | 2500 |

| Material: | PVC pipe fittings | Mechanical test report: | if |

| Power (W): | 10.5-22.5KW | Warranty: | 1 year |

| Main selling point: | automatic | Pipeline scope: | 50-110mm |

| brand: | FST | Power (kW): | 11 |

| place of origin; place of origin: | Jiangsu, China | Marketing Type: | New Products 2022 |

| Processing type: | Flaring machine |

Applications

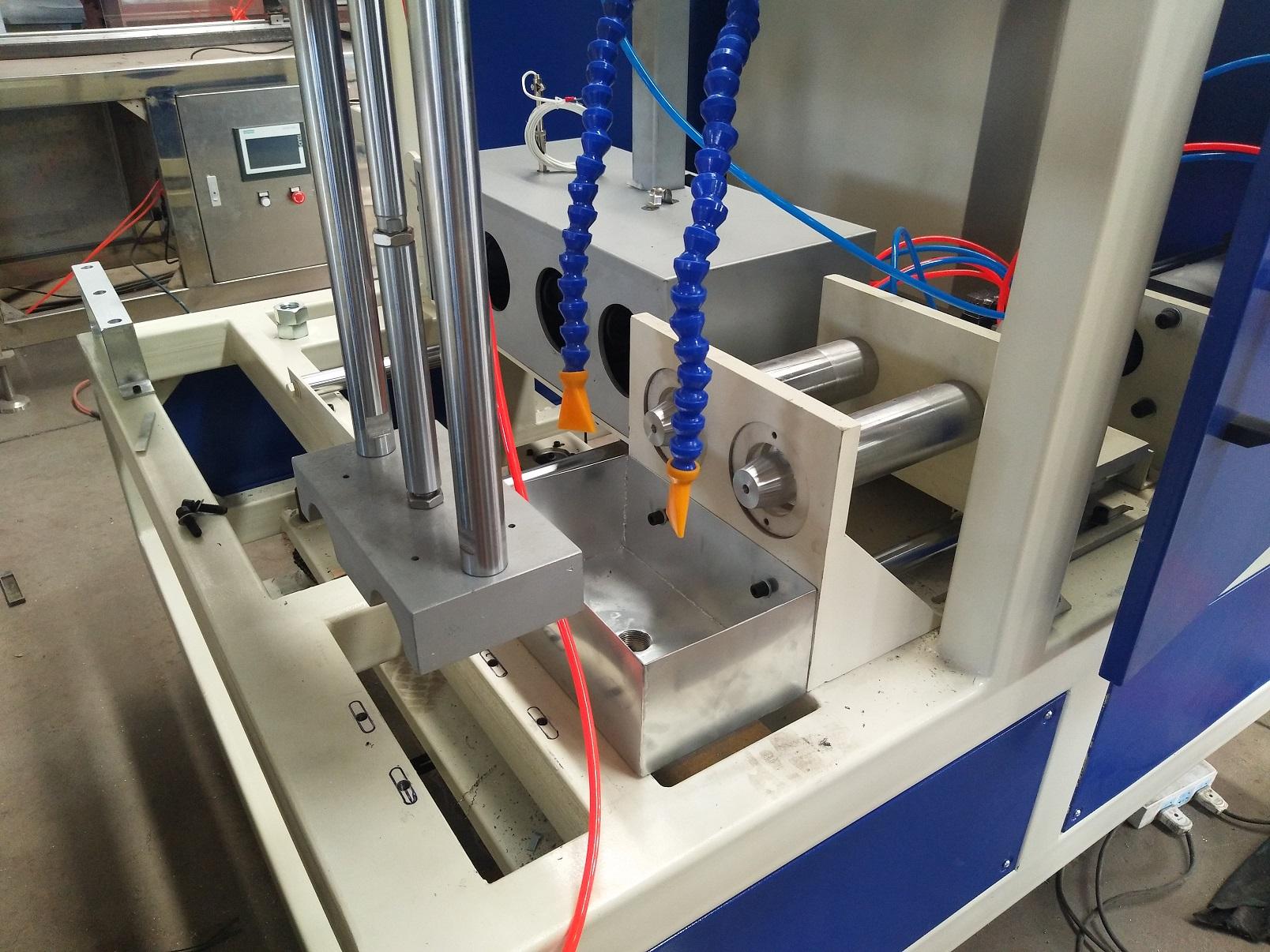

The equipment is made of pneumatic headstock structure and tailstock, all mechanical parts are of new quality

Steel manufacturing. Bearings use brand names. The head frame consists of a feeding device and a heating furnace

And to expand the working space, the furnace is made of stainless steel for heating, the furnace is equipped with its own unique

The temperature control system adopts a special eddy current structure, so that the tube can be rotated left and right to heat, so as to

The surface of the expansion tube can achieve uniform heating.

The tailstock is made of landings close to the electric body. The furnace control system consists of intelligent temperature control

Control table control, pneumatic and hydraulic components are all domestic famous brand products. equipment

The operator and the expansion of all actions are automatically controlled by the PLC controller.

Automatic Bell Machine Specifications | ||||||||

Specifications | SGK160 | SGK250 | SGK315 | SGK500 | SGK630 | |||

Pipe diameter (mm) | 50-160 | 63-250 | 160-315 | 250-500 | 400-630 | |||

Tube Wall Thickness(mm) | 2.9-15 | 2.9-15 | 2.9-15 | 2.9-22 | 2.9-22 | |||

Tube length (m) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | |||

Trumpet | R, U and square types | R, U and square types | R, U and square types | R, U and square types | R, U and square types | |||

Total power (kw) | 6.77 | 8.87 | 12.55 | 15.15 | 16.35 | |||

Working pressure (Mpa) | 4-6.3 | 4-6.3 | 4-6.3 | 4-6.3 | 4-6.3 | |||

Water consumption (m³/h) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |||

Output (pieces/hour) | 2-40 | 2-40 | 2-35 | 2-30 | 2-30 | |||

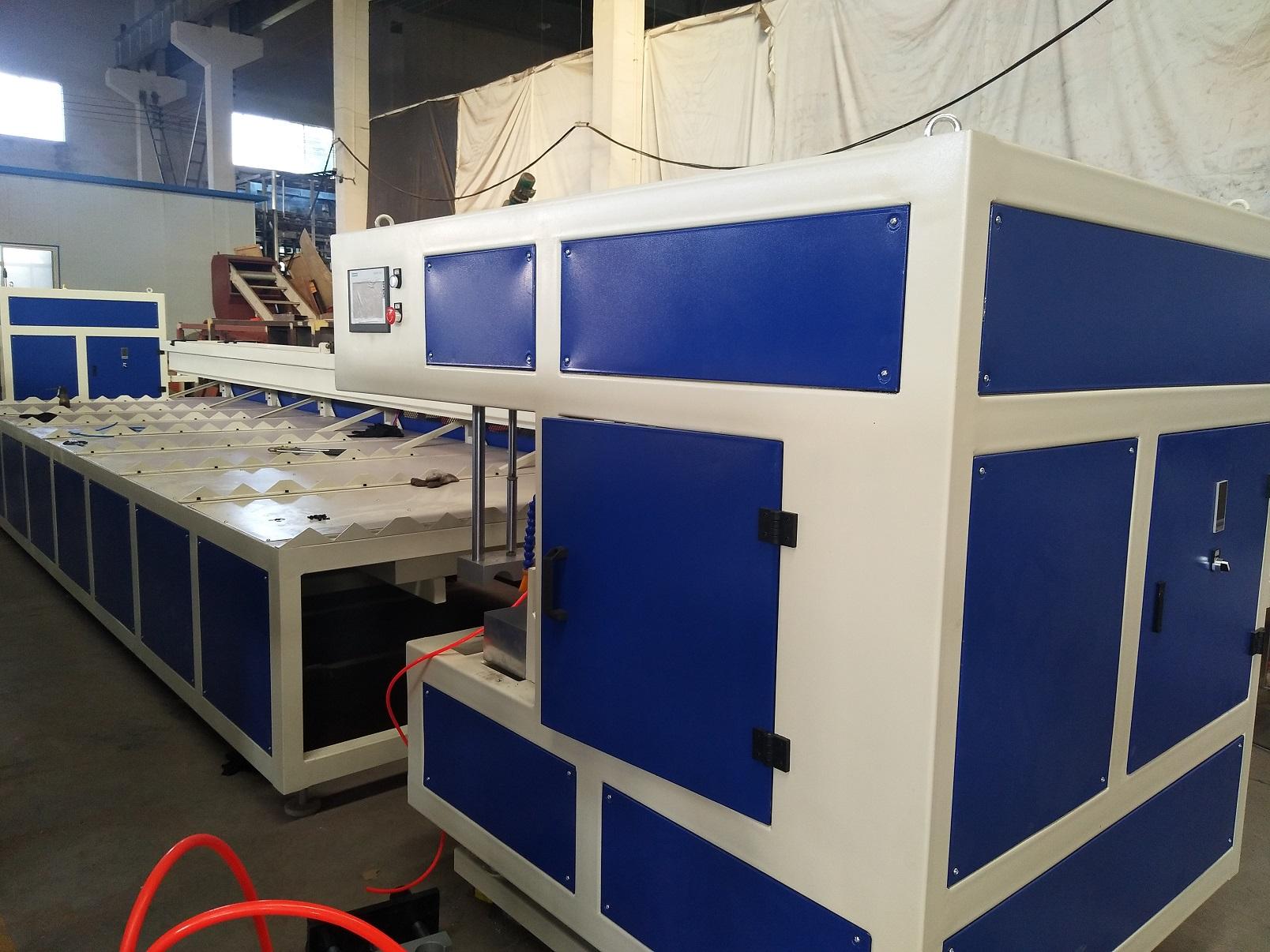

Dimensions (LxWxH) | 6600x1800x1800MM | 6800x1800x1850MM | 7500x2350x2100MM | 7800x4000x2000MM | 8000x4200x2100MM | |||

main feature

1. Simple operation

2. High degree of automation

3. Good after-sale service

4. Cost-effective and long life

-

Cheaper PVC pipe expanding machine in 2022

-

PVC pipe socket machine/manual expanding machine is suitable for 20-110mm PVC plastic pipe/manual pipe expanding machine

-

Fully automatic PVC plastic drainage pipe flaring making machine pvc pipe manufacturing factory cost

-

HDPE pipe flange flange and expansion machine

-

Hot selling pipe expanding machine

-

U-type R-type PVC solid wall pipe PVC PE double-wall corrugated pipe two oven automatic PVC pipe expansion and expansion machine

-

Fully Automatic PVC Pipe Flaring Machine/PVC R or U or Rectangular Socket Tube Making Machine

-

PVC plastic pipe flaring/flaring/socketing machine

-

Hot sale high quality oem pvc pipe flare making machine with best price extrusion line

-

Plastic Pipe Manual Flaring Machine PP PE PVC Pipe Flaring Machine

Other Products

-

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$50000.00 / set

$50000.00 / set -

$5000.00 / set

$5000.00 / set -

$99.00 / set

$99.00 / set -

$4500.00 / set

$4500.00 / set -

$25000.00 / set

$25000.00 / set -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set