Henan Fuyuan low-cost new egg tray machine small enterprise egg tray production line machine making egg tray

-

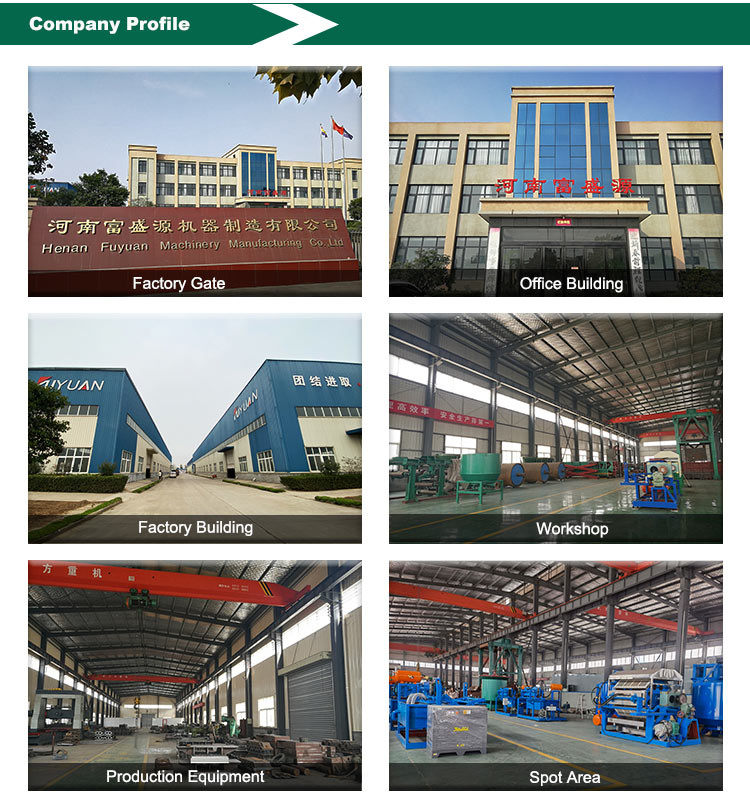

Supplier: Henan Fuyuan Machinery Manufacturing Co., Ltd. -

Region: Henan, China -

Contact: Ms trade lei -

Price: $7780.00 / 1 - 2 sets

$5820.00 / 3 - 4 sets

$4660.00 / 5 - 9 sets

$3699.00 / >=10 sets -

Min. Order: 1 set

| Drying method: | Natural drying, brick kiln drying, metal dryer | Showroom location: | Egypt, Canada, United Kingdom, United States, France, Germany, Vietnam, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania , Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia |

| Packaging Details: | 1. Outer packing: standard export wooden box 2. Inner packing: stretch film 3. Egg tray machine | Dimensions (L*W*H): | 2800*1400*1700mm |

| Applicable industries: | Manufacturing plant, farm, egg tray maker | Video external inspection: | if |

| weight: | 3000 kg | color: | custom color |

| Voltage: | 220v/380v | port: | Qingdao, Tianjin, Shanghai Port or other major Chinese ports |

| strength: | 37kW | Product Category: | Egg tray machine |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Egg Tray | capacity: | 1000-8000/hour |

| Production capacity: | 1000~8000 pieces/hour | Packaging Preview: | |

| place of origin; place of origin: | Henan, China | automation: | Fully automatic |

| Raw materials: | Waste books, waste newspapers, waste paper boxes | Core Components Warranty: | 1 year |

| product name: | Egg tray machine | Mold Type: | 6-pin, 10-pin, 12-pin, 18-pin, 30-pin or customized |

| Processing type: | Pulp forming machine | Health status: | new |

| Supply capacity: | 30 sets per month | Mold material: | plastic or aluminium |

| Dry fuel: | Coal, Timber, Diesel, Natural Gas, LPG | Warranty: | 1 year |

| brand: | Fuyuan | manufactures: | Egg plate, egg box, fruit plate, shoe plate, wine plate, cup plate |

| Core components: | PLC, Pressure Vessel, Engine, Gear, Motor, Pump, Bearing, Gear Box, Egg Tray 3 | Mechanical test report: | if |

| Marketing Type: | New Products 2022 |

Small business egg tray production line new machine to make egg tray

| machine type | 1*3 | 1*4 | 3*4 | 4*4 | 4*8 | 5*8 | 5*12 | 6*12 |

| Yield (p/h) | 1000 | 1500 | 2000 | 2500 | 4000 | 5000 | 6000 | 8000 |

| Waste paper (kg/h) | 120 | 160 | 200 | 280 | 320 | 400 | 480 | 640 |

| Water (kg/h) | 300 | 380 | 450 | 560 | 650 | 750 | 900 | 1040 |

| Electricity (kw/h) | 32 | 45 | 58 | 78 | 80 | 85 | 90 | 100 |

| workshop area | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| drying area | no need | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

Note: 1. More plates, less water consumption

2. Power refers to main components, excluding drying line

3. All fuel usage ratio is calculated at 60%

4. The length of the single-layer drying line is 42-45 meters, the double-layer drying line is 22-25 meters, and the multi-layer can save the workshop area

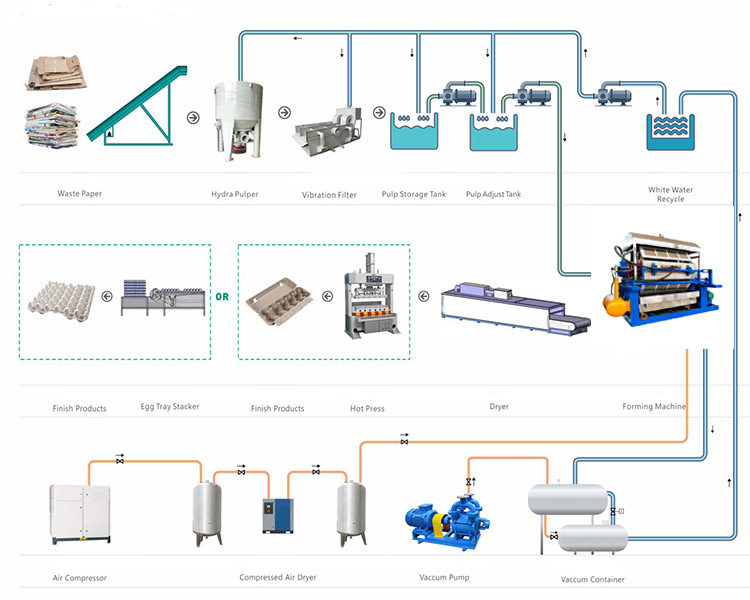

1. Pulping system

(1) Put the raw materials into the pulper, add an appropriate amount of water and stir for a long time to make the waste paper into pulp and store it in the storage tank.

(2) Put the pulp in the pulp tank into the pulping tank, adjust the slurry concentration in the pulping tank, pass the white water in the return tank and the thick pulp in the storage tank, and further stir through the homogenizer. After adjusting to the applicable pulp, it is put into the feeding pond for the forming system.

Equipment used: pulper, homogenizer, slurry pump, vibrating screen, pulp mill

2. Forming system

(1) The pulp in the feeding trough is supplied to the forming machine and is adsorbed by the vacuum system. The mold on the equipment to be formed leaves the pulp on the mold, sucks out the white water and transports it back to the pool through the vacuum pump.

(2) After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding mold to the rotating mold, and sent out from the transfer mold.

Equipment used: molding machine, mold, vacuum pump, vacuum tank, pump, air compressor, mold cleaning machine

3. Drying system

(1) Natural drying method: The product is directly dried by the weather and natural wind.

(2) Traditional drying: brick tunnel kiln, the heat source can choose natural gas, diesel, coal, dry wood, liquefied petroleum gas and other heat sources.

(3) New multi-layer drying line: 6-layer metal drying line saves more than 30% energy than transmission drying. The main heat sources are natural gas, diesel, liquefied petroleum gas, methanol and other clean energy.

4. Auxiliary packaging of finished products

(1) Automatic stacker

(2) Baler

(3) Conveyor belt

main feature

High-precision servo motor drive, high-efficiency and energy-saving drying line.

1. Adopt precision deceleration servo motor for forming and transmission to ensure smooth and fast operation.

2. The absolute value encoder is used to achieve precise correction.

3. It adopts bronze casting dynamic and static ring structure, which is more suitable for product dehydration process.

4. The mechanical structure is adopted to ensure that both sides of the mold are evenly closed.

5. Large capacity; low water content; saving drying cost.

The raw materials are mainly from reed pulp, straw pulp, pulp, bamboo pulp, wood pulp and other pulp boards, as well as waste cardboard, waste paper box paper, waste white paper, and waste pulp from paper mills. Source and easy to collect. The required operators are 5 people/shift: 1 in the pulping area, 1 in the molding area, 2 in the cart, and 1 in the packaging.

-

Paper Egg Tray Making Machine for Small BusinessesMachine for Fabricating Paper Egg Trays for Small Businesses

-

Factory supply low price fully automatic napkin machine napkin making machine price

-

Small Manufacturing Machine Automatic Toilet Paper Rewinder Complete Equipment

-

6kw High Speed Fully Automatic Disposable Paper Cup Machine Price India Marketing Copper Motor GSM Power Engine Pump Technology

-

Paper cup machine automatic paper cup machine paper cup machine price

-

Fully automatic machine for making disposable coffee cups

-

High Quality Paper Cup Production Making Machine Price,paper Cup Making Machine

-

Automatic V Fold Facial Tissue Hand Towel Paper Making Processing Machine Production Line

-

Small Pocket Envelope Making Machine for envelope

-

Automatic High Speed Paper Cup Making Machine With Online Handle Applicator/Fixing

Other Products

-

$4540.00 - $7500.00 / set

$4540.00 - $7500.00 / set