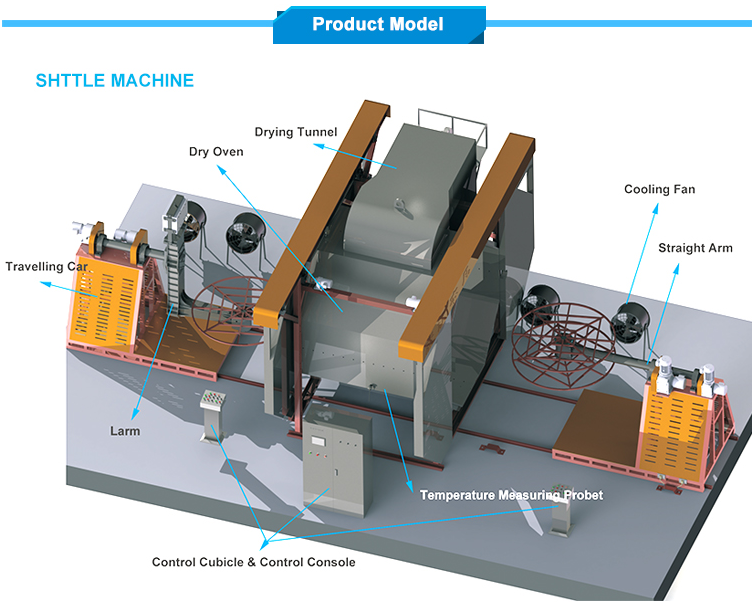

JC-3000CS Production Water Tank Shuttle Rotomolding Machine

-

Supplier: Ningguo Jingcan Rubble & Plastic Products Co., Ltd. -

Region: Anhui, China -

Contact: Mr shenhong Kang -

Price: $30000.00 /set -

Min. Order: 1 set

| Health status: | new | year: | 2019 |

| port: | Shanghai | strength: | 30KW |

| application: | rotomolding, water tank | weight: | 13OOOKG |

| Plastic Processing: | physical education | automatic: | Yes |

| Supply capacity: | 5 sets per month | place of origin; place of origin: | Anhui, China |

| payment terms: | letter of credit, wire transfer | Warranty: | 1 year |

| Voltage: | 380V, 220v-415v | strength: | three phase |

| After-sales service provided: | Free spare parts, online support, engineers to repair machinery overseas | Dimensions (L*W*H): | 10000*7000*4000 |

| brand: | Jingcan | Packaging Details: | Suitable for export packaging |

Ningguo Jingcan Rubber and Plastic Products Co., Ltd. is located in the National Economic and Technological Development Zone of Ningguo City, Anhui Province, China. The company focuses on rotomolding research and technology development, and supplies various rotomolding machinery and molds to developing countries around the world with rich experience. production of rotary products.

We never give up innovation and development, not only for the best machinery, but also for green living people on earth. No pollution, no noise, good environment, build a beautiful future with our hands.

Shuttle Rotomolding Machine Jc-3000cs Water Tank Production Mould

JC series shuttle rotomolding machine integrates products from the perspective of customers' general needs, individual needs and industry trends. Practical man-machine interface makes it convenient and quick to set process parameters of different products. Adopt programmable control technology PLC, improve system work efficiency and reliability, reduce integration cost and maintenance frequency; adopt frequency conversion technology, reduce energy consumption, machine fatigue strength, and improve machine life

main feature

1) The linear structure is simple and easy to install and maintain.

2) Pneumatic part, electrical part and operation part all adopt advanced world famous brand components.

3) The high pressure double crank controls the mold opening and closing.

4) The operation is automated, intelligent, and pollution-free

5) Use the connector to connect with the air conveyor, which can be directly connected to the filling machine in series.

Mechanical part:

It consists of a tandem arrangement of a central oven that shares two cooling/loading/unloading stations, one on each side of the oven assembly. The oven has a cylindrical horizontal design. ROTOLINE pioneered the manufacture of machines with cylindrical ovens, which provide uniform airflow in all areas of the oven, avoiding "dead spots".

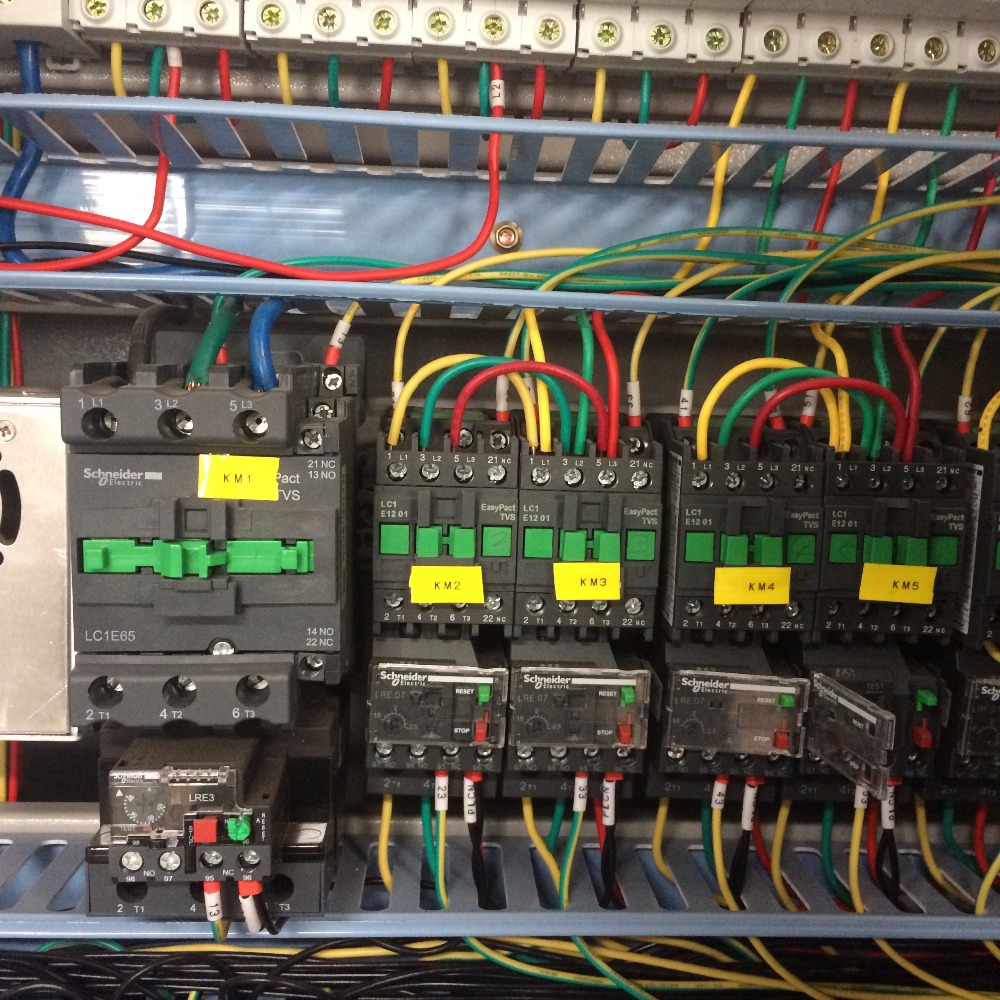

Electrical parts:

The machine is equipped with a universal panel in which all programmable and electromechanical components such as PLC (Programmable Logic Controller), computer, contactors, motor circuit breakers, power supplies, transformers, VFD (variable frequency drives), Buttons, selector switches and light/audio alarms. This panel is mainly used to set recipe parameters for production.

Burner system:

The heating system of the Rotoline machine is completed by a gas burner. The machine is equipped with a burner that can use two different types of gas, NG (natural gas) and LPG (liquefied petroleum gas).

Car/Weapon:

Shuttle machine models are available in two cars, available with a straight arm or an optional offset arm "C", both constructed with reinforced construction and heat treated to relieve steel stress.

Administrative Control:

The PLC is loaded with a software management control system that gathers information from multiple sensors (such as temperature and pressure), is installed in various parts of the machine, performs all interlocking and control functions for the operation of the machine, and provides the controller with specific and concise input of. Gas burner.

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* View our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers can repair machinery overseas.

* Moulds are available.

1 30% payment as deposit

2 70% before shipment

-

Professional Manufacturer Nissei ASB Machinery Plastic Injection Stretch Blow Molding Cosmetic Bottle Mold

-

Factory Price High Quality SJ-A50 Single/Double Wrap Film Blowing Machine

-

Chinese supplier of full automatic tennis ball making machine

-

PP FILM BLOWING MACHINE

-

Fangyuan Custom Automatic Vacuum EPS Foam Bicycle Helmet Liner Manufacturing Foam Plastic Molding Machine

-

Medicine Bottle Blow Molding Machine Small HDPE pehd PP ABS PS Plastic Automatic Cheap Low Price Stretch Extrusion

-

plastic vacuum machine making toy ball doll pvc vinyl toy football machine

-

ABS Furniture Plastic Blow Molding Machine Price

-

USB Interface Vertical Injection Molding Machine Price Favorable

-

Factory Price Semi Automatic 4 Cavity PET Plastic Bottle Blow Molding Machine Plastic Bottled Water Production Line

Other Products

-

$4500.00 - $5000.00 / set

$4500.00 - $5000.00 / set -

$10500.00 / set

$10500.00 / set -

$4000.00 / set

$4000.00 / set