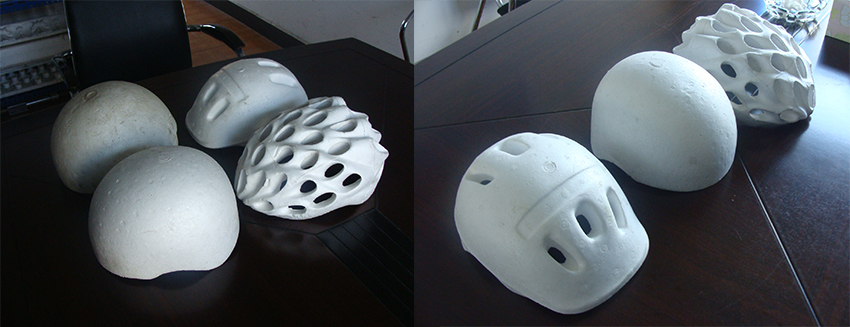

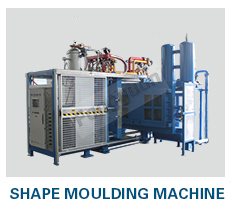

Fangyuan Custom Automatic Vacuum EPS Foam Bicycle Helmet Liner Manufacturing Foam Plastic Molding Machine

-

Supplier: Hangzhou Fangyuan Plastics Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms ying huang -

Price: $40000.00 /set -

Min. Order: 1 set

| Origin: | Zhejiang, China | Mechanical test report: | if |

| strength: | 50 | weight: | 10 tons |

| Applicable industries: | earnings per share | Name: | Bicycle Helmet Forming Machine |

| Local service locations: | Egypt, Brazil, India, Mexico | brand: | square circle |

| Core components: | PLC, motor, pump | application: | TV packaging, fish box, vegetable and fruit box, EPS box, building |

| color: | Blue Bicycle Helmet Forming Machine | Showroom location: | Egypt, Turkey, Vietnam, Saudi Arabia, Indonesia, Pakistan, India, Algeria |

| automation: | automatic | After-sales service provided: | With overseas service center |

| After Warranty Service: | On-site maintenance and repair services | Plastic processing: | earnings per share |

| Certification: | ISO9001, CEISO9001:2015 | Dimensions (L*W*H): | 4500*6200*4100 |

| Core component warranty: | 1 year | Warranty: | 1 year, 1 year |

| Die size: | According to product size | advantage: | High efficiency and small footprint |

| Marketing Type: | normal product | HS: | 84778000 |

| Main selling points: | automatic | port: | Shanghai |

| Blow molding type: | foam machine | Package preview: | |

| Health status: | new | Supply capacity: | 2000 sets per year |

| payment terms: | L/C, T/T, 20% T/T, balance L/C | Video outbound inspection: | if |

| Voltage: | 380V | Packaging Details: | wooden. HS 84778000. Custom eps foam bike helmet molding machine |

| Product maximum height: | 180 |

SPZ9M bicycle helmet forming machine

1. The machine adopts PLC control, touch-type visual human-machine interface, and can easily set and select time and process parameters according to the requirements of different products.

2. This machine adopts the pressure heating control method. The heating system is equipped with a supplementary balance valve control, which can effectively adjust the steam pressure at the outlet of the steam valve, and achieve different outlet pressures in different heating stages through specific control, so as to increase product stability. sex. Users can adjust it according to their needs.

3. The machine is driven by a hydraulic system, equipped with a differential circuit, and runs smoothly.

4. The machine is equipped with a pressure feeding system, and the user can choose the pressure feeding method according to the process to achieve more sufficient feeding into the mold, thereby reducing defective products caused by insufficient feeding.

5. Steam, compressed air, cooling water, and vacuum purge pipelines are located above or below the machine for easy maintenance, and each pipeline has a different color. Among them, the compressed air pipeline is a rectangular pipeline above the pressure plate, which is generally the same color as the machine.

6. The distance between the movable mold and the fixed mold is detected by a rotary encoder, and the distance is converted into a number and displayed directly on the touch screen. The feeding interval and other positions of the machine can be adjusted by simply adjusting the relevant values on the touch screen.

7. The system has perfect fault detection function. For example: machine safety, motor overload, etc., and troubleshooting methods are available online.

8. The machine has multiple safety protection devices:

A. Motor overload is protected by thermal relay.

B. The safety door is closed and protected by a proximity switch.

C. When the motor fails, the computer will automatically shut down and give an alarm

The lights come on.

D. The heating system is controlled by multiple sensors, which can control the heating

precise.

|

No. |

thing |

unit |

Technical data |

|

|

1 |

Die size |

mm |

According to product size |

|

|

2 |

Product Size |

mm |

According to product size |

|

|

3 |

product height |

mm |

180 |

|

|

13 |

compressed air |

main entry |

inch |

2.5 inches |

|

work pressure |

MPa |

0.6~0.8 |

||

|

consume |

rice3/cycle |

1.4 |

||

|

14 |

drainage system |

Diameter |

inch |

5 inches |

|

15 |

Pump |

pressure |

High pressure + low pressure (MPa) |

16+5 |

|

16 |

engine |

hydraulic |

kW/rev/min |

7.5/980 |

|

feed |

kW/rev/min |

1.5/3000 |

||

|

number 17 |

Tank volume |

I |

240 |

|

|

18 |

Dimensions |

length x width x height |

mm |

4500×6200×4100 |

|

19 |

cycle |

sec/cycle |

|

|

|

20 |

weight |

time |

10 |

|

-

Professional Manufacturer Nissei ASB Machinery Plastic Injection Stretch Blow Molding Cosmetic Bottle Mold

-

Factory Price High Quality SJ-A50 Single/Double Wrap Film Blowing Machine

-

Chinese supplier of full automatic tennis ball making machine

-

PP FILM BLOWING MACHINE

-

Medicine Bottle Blow Molding Machine Small HDPE pehd PP ABS PS Plastic Automatic Cheap Low Price Stretch Extrusion

-

plastic vacuum machine making toy ball doll pvc vinyl toy football machine

-

ABS Furniture Plastic Blow Molding Machine Price

-

USB Interface Vertical Injection Molding Machine Price Favorable

-

Factory Price Semi Automatic 4 Cavity PET Plastic Bottle Blow Molding Machine Plastic Bottled Water Production Line

-

ABC three-layer PE co-extrusion blown film machine

Other Products

-

$20000.00 / set

$20000.00 / set -

$8800.00 / set

$8800.00 / set -

$42000.00 / set

$42000.00 / set -

$57000.00 / set

$57000.00 / set