High Quality Used Rubber Mixing Mill Price, Lab Rubber Two R

-

Supplier: Dongguan Right Instrument Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Forrest Young -

Price: $6500.00 /set -

Min. Order: 1 set

| Packaging Detail: | High Quality Used Rubber Mixing Mill Price, Lab Rubber Two Roll Mill is packed in a polybag, then packed as export safety wooden case; | Type: | Open Mixing Mill; |

| Year: | 2019; | Roller face width: | 320mm; |

| Brand Name: | RIGHT; | Port: | Shenzhen; |

| Roller Diameter: | 120,160,200,250mm; | Warranty: | 12 Months; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Roller temperature: | RT~300℃; |

| Place of Origin: | Guangdong China (Mainland); | Picking device: | SUS304 Stainless steel hopper; |

| Product name: | High Quality Used Rubber Mixing Mill Price, Lab Rubber Two Roll Mill; | Temp Accuracy: | ±3℃; |

| After-sales Service Provided: | Field installation, commissioning and training; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

| Dimension(L*W*H): | 1000x1100x1400mm; | Mixing capacity: | 0.3~2kg; |

| Weight: | 2T; | Voltage: | 220V/380V; |

| Supply Ability: | 200 Set/Sets per Month; | Condition: | New; |

| Heating method: | electrical heating; | Certification: | ISO; |

| Power(W): | 4.5KW; |

High Quality Used Rubber Mixing Mill Price, Lab Rubber Two Roll Mill

What Specification Of Rubber Two Roll Mill?

Technical Parameter

Model Project | RT-110A-1 | RT-110A-2 | RT-110A-3 | RT-110A-4 |

Roller Diameter (metric /inch) | 120mm/4in | 160mm/6in | 200mm/8in | 250mm/10in |

Roller face width | 320mm | 320mm | 320mm | 320mm |

Mixing capacity | 0.3~2kg | 0.5~3kg | 1~10kg | 2~15kg |

Picking device | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper |

Roller temperature | RT~300℃ | RT~300℃ | RT~300℃ | RT~300℃ |

Heating method | electrical heating | electrical heating | electrical heating | electrical heating |

Temp Accuracy | ±3℃ | ±3℃ | ±3℃ | ±3℃ |

temperature controller | PID control | PID control | PID control | PID control |

Roller Rev | frequency control | frequency control | frequency control | frequency control |

Roller ratio adjusted according requirements | 1:1.22/1:1.35 1:1.4 | 1:1.22/1:1.35 1:1.4 | 1:1.1/1:1.22 1:1.4/1:1.7 | 1:1.1/1:1.22 1:1.4/1:1.7 |

Roller hardness | 50~60HRC | 50~60HRC | 50~60HRC | 50~60HRC |

Roller processing | Mirror polishing chrome plated | Mirror polishing chrome plated | Mirror polishing chrome plated | Mirror polishing chrome plated |

Roller spacing | 0.1~8mm adjustable | 0.1~8mm adjustable | 0.1~8mm adjustable | 0.1~10mm adjustable |

Spacing display mode | Calibration/digital display | Calibration/digital display | Calibration/digital display | Calibration/digital display |

Safety device | Collision type emergency stop | Collision type emergency stop | Collision type emergency stop | Collision type emergency stop |

Safety device number | 7 PCS | 7 PCS | 7 PCS | 7 PCS |

Special function | Emergency stop inversion | Emergency stop inversion | Emergency stop inversion | Emergency stop inversion |

Motor power | 4.5KW | 5.5KW | 7.5KW | 15KW |

Power voltage | 3phase,AC380V | 3phase,AC380V | 3phase,AC380V | 3phase,AC380V |

Dimension | 1*1.1*1.4(M) | 1*1.1*1.5(M) | 1.5*1.2*1.5(M) | 1.5*1.3*1.6(M) |

Weight | ≈2T | ≈2.5T | ≈3.4T | ≈4T |

Equipment summary:

High Quality Used Rubber Mixing Mill Price, Lab Rubber Two Roll Mill is suitable for plastic industry polymer material mixing and processing such as, PVC, color master

batch. Making the raw material and compound mixing, and achieve the required color and quality. The machine

adopts special heated mold, roll surface temperature uniformity, never take off a layer, sample thickness can be

mixed, the machine safety protection device, convenience to use.

Reference standard:

GB 6038-2006 Rubber ingredients of rubber testing, mixing and Vulcanization equipment and operating

procedures.

GBT 13577-1992 Mill for rubber and plastics

HGT 2149-2004 Open rubber mixing machine, plastic mixing mill test methods

JBT 53113-1999 Open plastic mixing mill product quality grading

Technique Feature:

1.The core technology from Taiwan, The main parts adopt the French schneider.

2.The whole floor,easy installation, driving mode is uniaxial output ensure the torsion big,Imported bearings

reduce rubbing force to ensure save electricity, low noise and rubber thickness uniform parallel controllable.

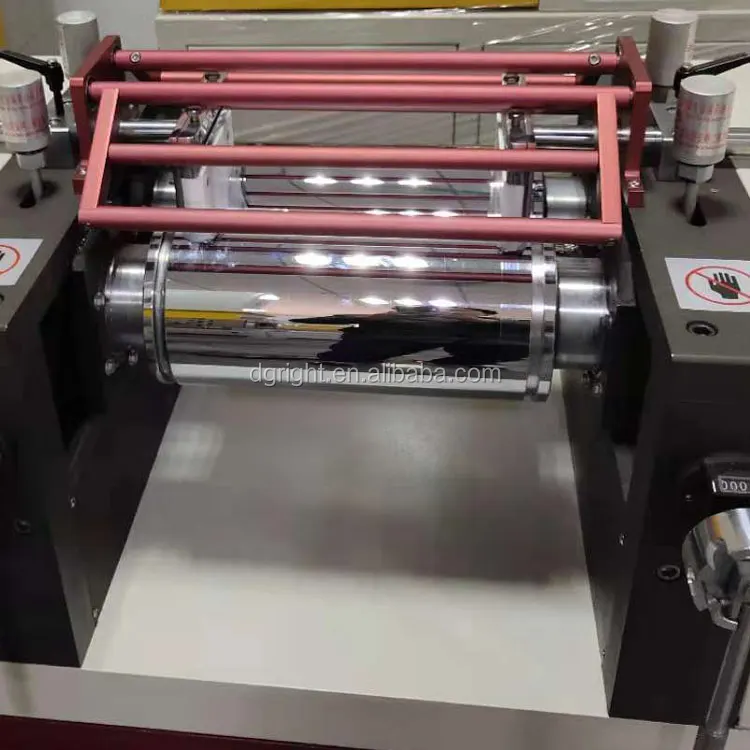

3.Roll adopts the vanadium titanium alloy chilled cast iron,roll hardness(HRC)50-60,surface is hard

wear-resisting, durable. Roller lumen finish machining to ensure that the roller body cooling quickly and evenly.

4.The machine adopts manual adjustment mode, Thickness control precision,easy operation,High safety factor .

5.The machine is equipped with an emergency brake, When emergency accidents,four corners have

emergency switch, a number of brake system, convenient quick stop machine.

6.Transmission device adopts hardened reducer,compact structure,transmission efficiency,little noise.

7.Automatic oiling device to ensure that long-term oil for driving part,Make up the pump forget supply damage

to part of serious consequences.

8.Two motor driven,arbitrary roller speed ratio before and after implementation,easy to operation;

9.Integral plate,easy installation.Driving mode is uniaxial output to ensure the big torque,imported bearings

to reduce friction to save electricity, reduce noise, and Rubber thickness uniform parallel controllable.

10.Transmission device adopts double double frequency converter control,Low noise, long service life.

What Product Picture Of Rubber Two Roll Mill?

Click for More Information!!!

*Shippment

-By sea

-By plane

-By couriers, TNT, DHL, FEDEX, UPS, etc.

*Standard Export carton

1.Inner Package: Thin plastic film surround the machine;

2.Outer Package: Internationally standard package export safety wooden case.

What Related Product Of Rubber Two Roll Mill?

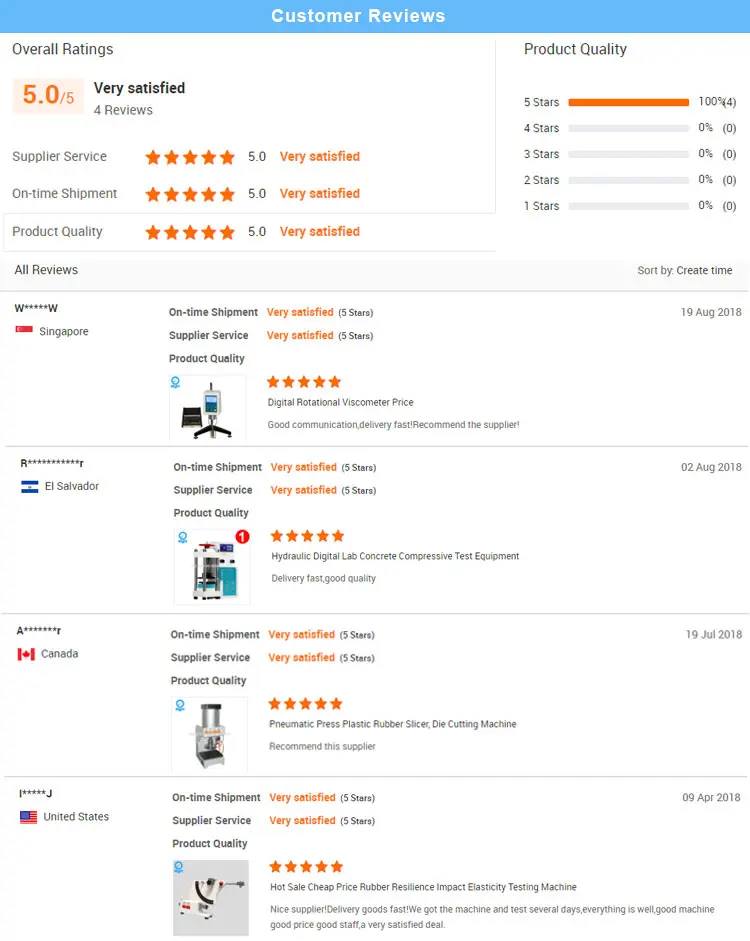

Dongguan Right Testing Machine Co.,Ltd is specialize in rubber and plastic testing machine over 10 years,With our advanced technologies and best customer service, Our product has exported to more than 100 countries and regions,which win favorable comments from customers worldwide.

Our production line have turning machine,griding machine,milling machine,CNC machining center and sheet metal bending machine,design department has 5 people special for design and research new product.With these advantages,we can control product quality from source.

If you have any inquiry or concern,Sales and after service department will reply you within 24 hours.

CLICK HERE BACK TO HOME

Q1: How long is the delivery time?

A:Normally 5-10 working days after received deposit,we have our own factory,the delivery time can be adjust flexible.

Q2: What is the warranty for the equipment?

A: One year. We can provide you lifelong technical support.

Q3: What is the payment terms?

A: T/T, L/C, Western Union, etc

Q4: How about the products quality?

A: Our products apply to ISO, ASTM, GB, etc

Q5: Is it OK to print my logo on machine product?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q6. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

or 100% L/C at sight .

Q7: Can we test sample before place order?

A: Of course,we can test sample and provide test report to you with free.

How To Contact Us?

Send Your Inquiry Details in the Below,Click "Send" Now!

-

Rubber grinder made in China

-

CE standard two-roll rubber mixing machine

-

Two-roll mill, two-roll rubber mill, rubber two-roll mill

-

Mini Rubber Sheet Rolling Machine, Rubber Silicone Mixing Machine, Rubber Rolling Machine

-

Laboratory double-roll rubber and plastic color mixing machine, high quality and low price

-

kneading machine, rubber kneading machine, kneading machine

-

XKP-560 Double Roller Rubber Crusher Waste Tire Rubber Crusher

-

EVA&Rubber Kneader

-

Factory direct sales of automatic material turning rubber and plastic PVC mixing electromechanical heating double-roller rubber mixing machine

-

New Double Roller Rubber Mixing Machine

Other Products

-

$1000.00 / set

$1000.00 / set -

$5000.00 / set

$5000.00 / set -

$1000.00 / set

$1000.00 / set