Factory direct sales of automatic material turning rubber and plastic PVC mixing electromechanical heating double-roller rubber mixing machine

-

Supplier: Dongguan Zhongli Instrument Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Cathy Lin -

Price: $3000.00 /set -

Min. Order: 1 set

| Health status: | new | Marketing Type: | New Products 2020 |

| Front roller speed (rpm): | 1 - 19 rpm | Video shipment inspection: | if |

| Package preview: | Dimensions (L*W*H): | 960*550*1150 mm | |

| temperature: | Room temperature~300℃ | Certification: | EU/ISO |

| Showroom location: | not any | Warm up time: | Room temperature~150℃ for about 20min |

| Weight (kg): | 380 kg | brand: | ZL |

| Roll ratio (front/rear): | 1:1.25 | Core components: | PLC, engine, motor |

| Voltage: | 380V | cooling method: | water cooling (option) |

| Mixing capacity: | 0.5-1kgs / 2-3kgs / 5-7kgs | weight: | 380 kg |

| Applicable industries: | Manufacturing plant, rubber and plastic industry | Reel Diameter(mm): | 16 mm |

| After warranty service: | online support | Origin: | Guangdong, China |

| Core component warranty: | 2 years | port: | Shenzhen |

| Mechanical test report: | if | Coil Length(mm): | 35 mm |

| Roller size: | Diameter 3.9"* L13.7" | product name: | Factory direct electric heating double roller rubber temperature machine |

| Warranty: | 2 years | Supply capacity: | Annual output of 200 electric heating double-roller rubber temperature machines |

| Temperature Accuracy: | ±3℃ | Drum rotation ratio: | Standard rotation ratio 1:1.25 |

| Packaging Details: | Manufactory direct selling automatic material turning rubber and plastic PVC mixer electric heating double-roller rubber temperature machine packed in plastic bags and exported in safe wooden boxes | Power (kW): | 2.5 |

| Main selling points: | long lasting | Year: | custom |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Electro heating Two Roll Rubber Warming Mill for any payment method |

Factory direct sales of automatic material turning rubber and plastic PVC mixing electromechanical heating double-roller rubber mixing machine

introduce:

plastic mill rubber mill

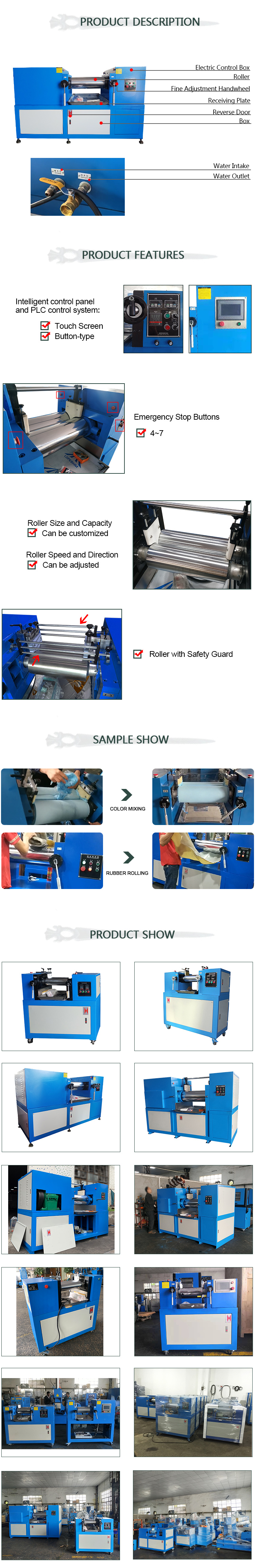

It provides unparalleled performance for mastication and mixing of natural rubber, synthetic rubber, EVA or PVC pellets and various chemical raw materials. This machine is mainly used for mastication, thermal grinding and mixing of natural rubber and synthetic rubber in rubber product factories.

application:

plastic mill rubber mill

It is widely used in the mixing of polymers such as polyvinyl chloride and color masterbatch in the rubber and plastic industry. It consists of rolls, bearings, gap adjustment devices, electrical control systems, safety devices, etc.

Technical Parameters:

|

Model

|

|

ZL-3018-76 |

ZL-3018-120 |

ZL-3018-160 |

ZL-3018-200 |

ZL-3018-230 |

ZL-3018-300 |

ZL-3018-400 |

|

Roll diameter |

mm |

76 |

120 |

160 |

200 |

230 |

300 |

400 |

|

Roll surface length |

mm |

300 |

350 |

350 |

500 |

650 |

650 |

900 |

|

Stirring capacity |

Kilogram |

0.002-0.6 |

0.002-2 |

0.002-2.8 |

0.002-5 |

0.005-10 |

1-15 |

5-30 |

|

Front roller surface speed |

Rotating speed |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

|

friction ratio |

|

1:1.30 |

1:1.35 |

1:1.35 |

1:1.35 |

1:1.27 |

1:1.27 |

1:1.27 |

|

Gap range |

mm |

0-3 |

0-6 |

0-6 |

0-8 |

0-12 |

0-12 |

0-15 |

|

driving force |

kilowatt |

1 |

1.5 |

2.2 |

7.5 |

11 |

30 |

37 |

|

heating method |

Electric heating, oil heating (optional) |

|||||||

|

cooling method |

water cooling (option) |

|||||||

|

Roll temperature |

Room temperature -- 300℃ |

|||||||

|

Roll hardness |

Hardness 50 ~ 60 |

|||||||

|

temperature accuracy |

±2°C (we use high-precision PID microcomputer controller) |

|||||||

|

safety devices |

It has 6 safety buttons and safety guards are optional |

|||||||

|

machine weight |

Kilogram |

160 |

460 |

660 |

860 |

1960 |

2960 |

3800 |

|

Dimensions |

mm |

1100x400x1180 |

1100x550x1380 |

1200x650x1380 |

2200x750x1380 |

2200x950x1580 |

2600x950x1580 |

5295x1789 x170 |

|

strength |

380V three phase 50-60hz |

|||||||

feature:

1. Roll structure: drilled roll, drilled roll, grooved roll

2. The speed ratio can be designed according to the customer's formula and processing requirements.

3. The frame, frame cap and base are welded and annealed to relieve stress.

4. The material of the roll is chilled alloy cast iron with a hardness of 70HB.

5. Braking and emergency stop devices to ensure the safety of personnel and equipment.

6. Automatic oil supply or grease lubrication, easy to maintain and protect the machine.

7. Humanized design control system ensures labor safety.

8. Gap adjustment method: manual or electric

Intelligent control panel and PLC control system:

1. Real-time data recording and export of mixing time, temperature (mixing chamber and front and rear rotors), punching pressure, current, torque, formula code.

2. The control system can set up to 20 mixing steps, saving 20 formula spaces.

3. The control system can remotely import process recipes and data monitoring, and communicate with MES through the Ethernet communication interface.

4. Reserve the Ethernet communication interface and 20% of the control points. A touch screen is provided.

Color customization:

-

Rubber grinder made in China

-

CE standard two-roll rubber mixing machine

-

Two-roll mill, two-roll rubber mill, rubber two-roll mill

-

Mini Rubber Sheet Rolling Machine, Rubber Silicone Mixing Machine, Rubber Rolling Machine

-

Laboratory double-roll rubber and plastic color mixing machine, high quality and low price

-

kneading machine, rubber kneading machine, kneading machine

-

XKP-560 Double Roller Rubber Crusher Waste Tire Rubber Crusher

-

EVA&Rubber Kneader

-

New Double Roller Rubber Mixing Machine

-

High Quality Open Mill/Two Roll Mixer/Rubber Mixer

Other Products

-

$4000.00 / set

$4000.00 / set -

$2560.00 / set

$2560.00 / set -

$2888.00 / set

$2888.00 / set -

$3100.00 / set

$3100.00 / set -

$5000.00 / set

$5000.00 / set -

$2800.00 / set

$2800.00 / set -

$5000.00 / set

$5000.00 / set -

$2300.00 / set

$2300.00 / set -

$2888.00 / set

$2888.00 / set -

$2650.00 / set

$2650.00 / set