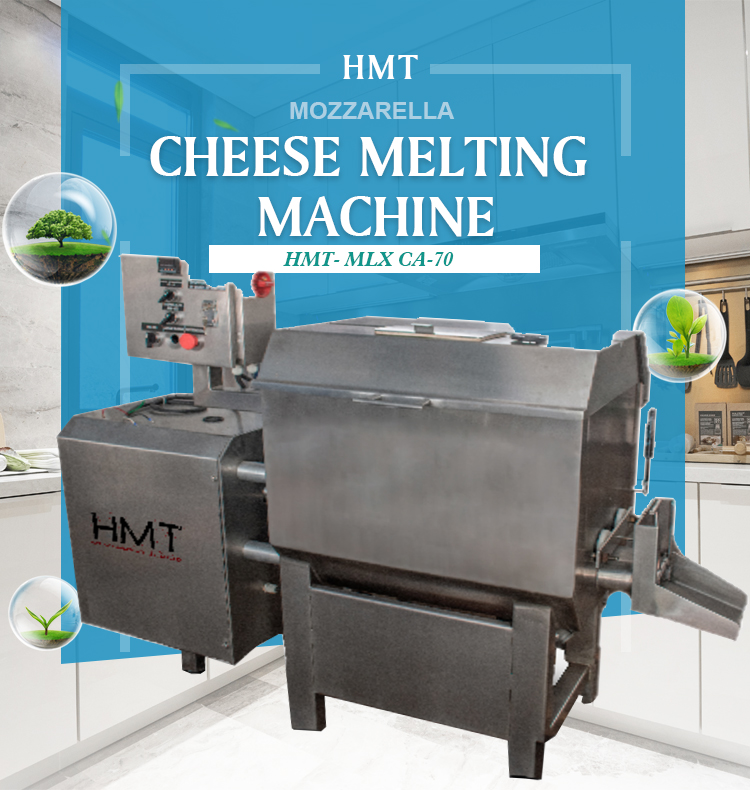

Professional Wholesale Mozzarella Cheese Chocolate Melting Machine

-

Supplier: HM Tecnologia S.A. de C.V. -

Region: La Libertad, El Salvador -

Contact: Mr Hember Melendez -

Price: $5000.00 /unit -

Min. Order: 1 unit

| payment terms: | Wire Transfer, Western Union, MoneyGram | Supply capacity: | 10 units per month |

| Voltage: | 220V/440V | port: | Puerto Acajutla / Puerto Manzanillo / Puerto Veracruz |

| Material: | Stainless Steel 304 | brand: | HMT |

| Showroom location: | Germany, Mexico, Spain, Argentina, Chile | Pressure steam feed: | 1kg/ha 1.5kg/hour |

| Mixer Type: | dairy industry | Main selling point: | high productivity |

| Packaging and Shipping: | 10 units per month. | After Warranty Service: | Online support, spare parts |

| delivery time: | 45 days | Local service location: | Canada, United States, Mexico, Russia, Spain, Japan, Argentina, Colombia, South Africa |

| Certification: | ISO 9001 | Health status: | new |

| Applicable industries: | Mechanical Repair Shops, Food and Beverage Plants, Farms, Food Stores, Food and Beverage Stores, Pharmaceuticals | Packaging Details: | Ordinary packaging is a wooden box. If it is exported to European countries, the wooden box will be fumigated. If the container is too tight, we will use pe film packaging or according to customer's special requirements. |

| After-sales service provided: | Preventive and corrective services. | place of origin; place of origin: | salvador |

| Warranty: | 1 year | After-sales service provided: | Online support |

| Function: | Cooking and casting of food |

cheese processing and melting machine

The cheese processing melting machine is a device designed and patented by our company for the cooking and pouring of food, through the controlled movement of our parallel helical belts, rotational movement + translation, we achieve a perfect elliptical movement. The result is maximum kneading, homogenization, yarn and pasteurization of the product.

Application areas:

1. The production of pasta cheese, such as quesillo, mozzarella, processed cheese, etc. Various pasta with cheese.

2. The making and cooking of refried beans.

3. Processing and pasteurization of various viscous sauces.

4. Processing and pasteurization of natural pulp such as zapote, papaya, orange pulp, etc.

Technical Description:

1. Rugged stainless steel construction AISI (American Iron and Steel Institute) nutritional grade 304.

2. Half-cane horizontal with jacket for low or high pressure steam passage.

3. Advanced flip cover with process viewer and safety sensor.

4. Manual or pneumatic knife product discharge nozzle

5. The mechanical sealing system is placed on the kneading slats for easy maintenance and cleaning

6. Electronic change of kneading plate speed

7. Product Pasteurization Digital Temperature Indicator

Available models and capacities

| Melting machine role model | cooking utensils role model | ||

cheese processing and melting machine

| aspect L*W*H/mm | volume LT | nominal consumption One | |||

cooking utensils

| capacity l/h | gear motor life value | ||||

main feature

1) Simple structure, easy installation and maintenance

2) Pneumatic part, electrical part and operation part all adopt advanced world-renowned brand components.

3) Double operation of the first and second stages of pneumatic or manual valves

4) Low energy consumption and high efficiency motor

5) Homogeneous block with high efficiency and low noise

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* View our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers can repair machinery overseas.

| port | |

| Packaging and Shipping | |

-

500L 1000L 2000L cheese production line mozzarella cheese making machine cheese barrel

-

Stainless Steel Cheese Making Cooking Bucket with Double Whisk

-

Ice cream production line/ice cream machinery

-

Fully automatic electric 50/L stainless steel 304 centrifugal milk cream separator

-

Stainless steel 25L new milk mixer

-

Fully automatic continuous UHT milk production line, UHT milk processing plant

-

Fully automatic ice cream factory production line equipment rod extrusion sandwich bon bon ball cone extruder

-

Small mozzarella cheese production line mozzarella cheese making machine watt

-

Hot sale cheap 200 liters vertical 100 500 liters milk cooling tank price

-

milk jug, milk bucket, stainless steel jug

Other Products

-

$7700.00 / unit

$7700.00 / unit -

$7700.00 / unit

$7700.00 / unit